Three-dimensional scaffold with controllable internal surface, and preparation method thereof

A three-dimensional stent, internal surface technology, used in medical science, surgery, additive processing, etc., to achieve the effect of easy operation, wide material applicability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

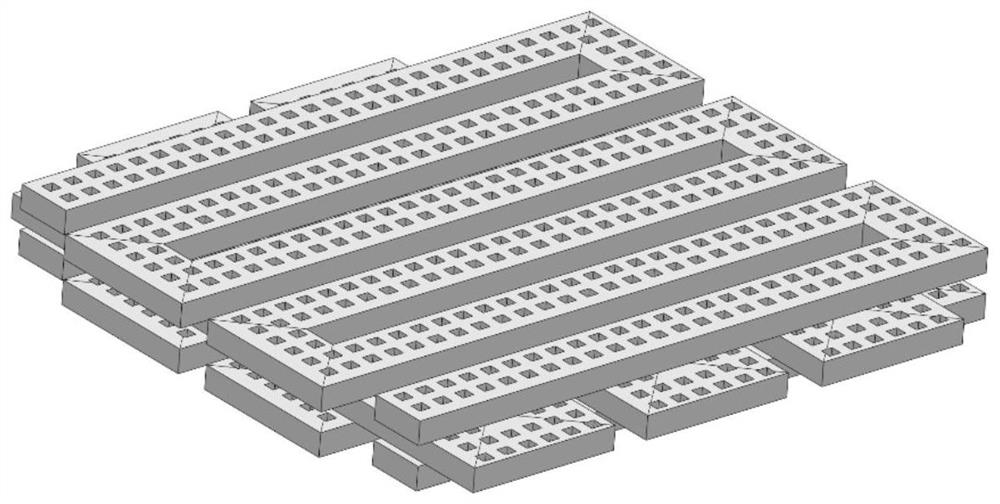

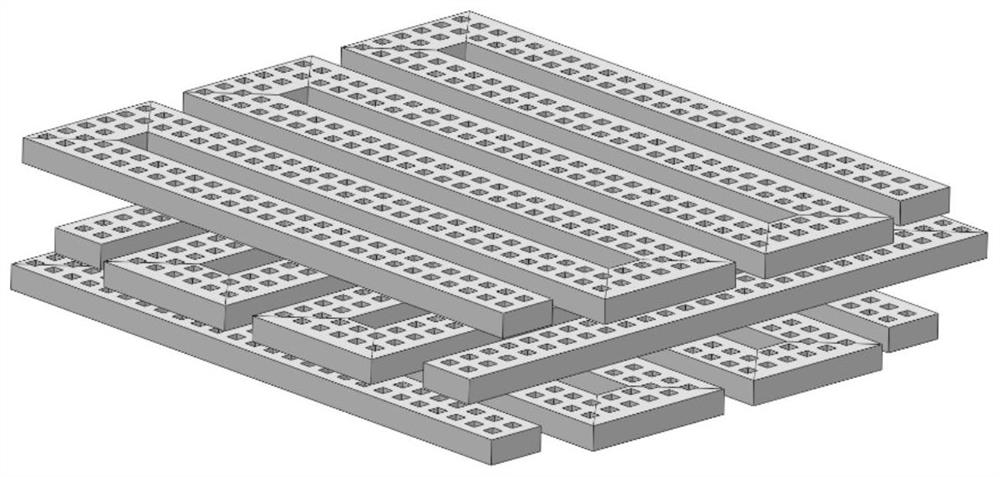

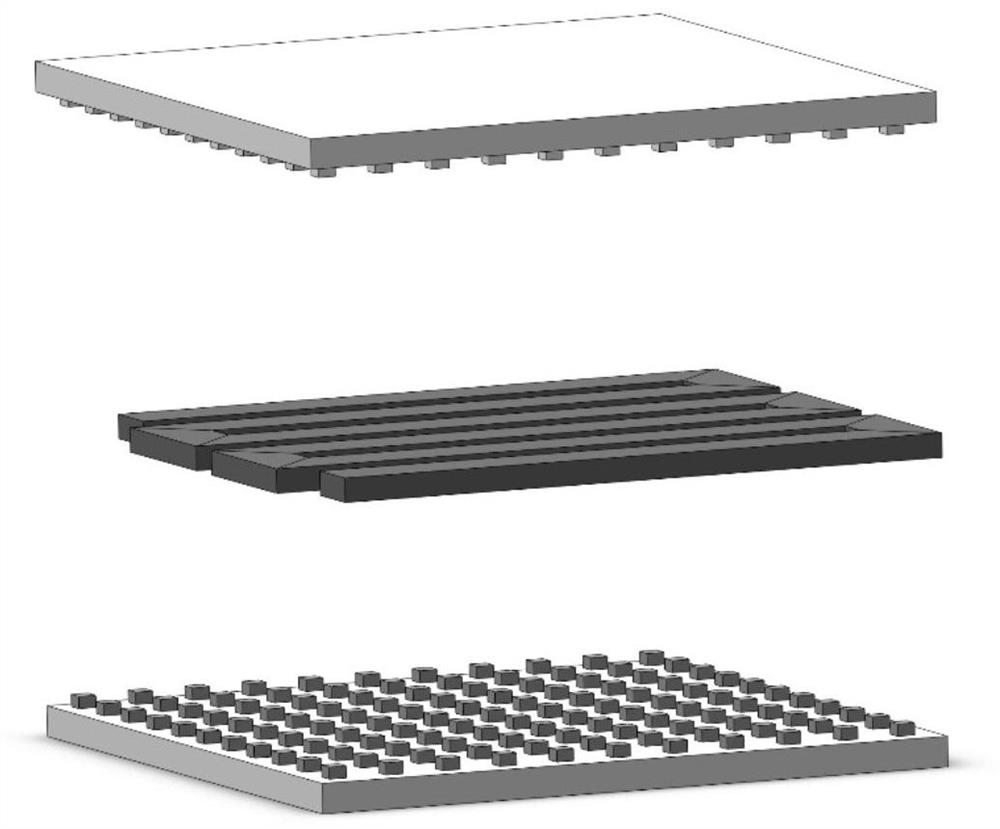

[0047] (1) Build as figure 1 The three-dimensional internal surface microtopography support model shown (when building the three-dimensional support model, the software SolidWorks 2017 was used to construct), and the support model was segmented into slices of 0.25mm (the segmentation figure is as follows figure 2 ), the two-dimensional sheet model is obtained, and its structure is as follows image 3 Shown in the middle layer;

[0048](2) Use a 3D printer to print polycaprolactone (PCL) wires according to the two-dimensional sheet model and its data, and prepare 3-10 two-dimensional sheet materials of this structure; wherein, the printing temperature is 80°C, The printing speed is 4mm / s, and the thickness of the two-dimensional scaffold sheet material is 0.25mm;

[0049] (3) Construct a pit-like pattern model with a size of 30×30 μm and an interval of 10 μm (when constructing a micro-pattern model, use the software CorelDrawX8 to construct it), and use a photolithography ma...

Embodiment 2

[0058] (1) Build as figure 1 The three-dimensional internal surface microtopography support model shown (when constructing the three-dimensional support model, the software SolidWorks 2017 is used to construct), and the support model is divided into 0.25mm slices to obtain a two-dimensional slice model;

[0059] (2) Use a 3D printer to print polycaprolactone (PCL) wires according to the two-dimensional sheet model and its data, and prepare 3-10 two-dimensional sheet materials of this structure; wherein, the printing temperature is 80°C, The printing speed is 4mm / s, and the thickness of the two-dimensional scaffold sheet material is 0.25mm;

[0060] (3) Construct a micro-groove pattern model with a size of 2 cm × 40 μm and an interval of 10 μm (when constructing a micro-pattern model, use the software CorelDrawX8 to construct it), and use a photolithography machine to make SU-8 photoresist on a silicon wafer Obtain the required micro-pattern through processes such as gluing, g...

Embodiment 3

[0066] (1) Build as Figure 12 The three-dimensional internal microtopography + poly(hydroxyethyl methacrylate) hydrophilic layer alternating scaffold model shown (when constructing the three-dimensional scaffold model, the software SolidWorks 2017 was used to construct it), and the scaffold model was segmented into slices of 0.25mm , to obtain a two-dimensional sheet model,

[0067] (2) Use a 3D printer to print polycaprolactone (PCL) wires according to the two-dimensional sheet model and its data, and prepare 3-10 two-dimensional sheet materials of this structure; wherein, the printing temperature is 80°C, The printing speed is 4mm / s, and the thickness of the two-dimensional scaffold sheet material is 0.25mm;

[0068] (3) Construct a pit-shaped pattern model with a size of 30 μm×30 μm and an interval of 10 μm (when constructing a micropattern model, use the software CorelDraw X8 to construct it), and use a photolithography machine to make SU-8 photoresist on silicon On the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com