A two-stage swirl urea injector

A technology of injector and urea, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of difficult to meet the atomization effect, flow consistency, poor processing technology, and difficult to ensure the consistency of atomized particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

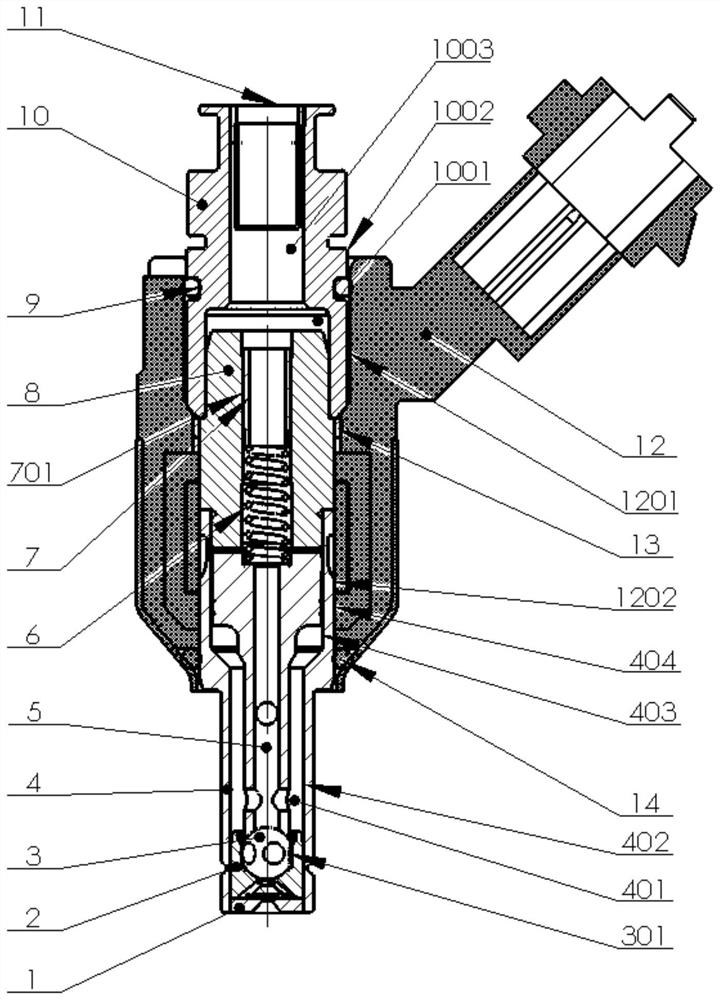

[0028] Structure of the present invention, further concrete description is as follows in conjunction with accompanying drawing:

[0029] see Figure 1 to Figure 6 , the two-stage swirl urea injector shown in the figure mainly includes the electromagnet part 12, the oil inlet joint, the iron core spring assembly and the injection valve assembly. The oil inlet joint includes a filter screen support 10, a filter screen 11 and an O-ring seal 9. A middle hole 1003 is arranged in the filter screen support 10 , and the filter screen 11 is placed in the middle hole 1003 .

[0030] The iron core spring assembly includes an iron core 8 , a spring upper seat 7 and a spring 6 .

[0031] The injection valve assembly includes a valve stem 5 , a nozzle body 4 , a steel ball 3 , a valve seat 2 , and a nozzle plate 1 .

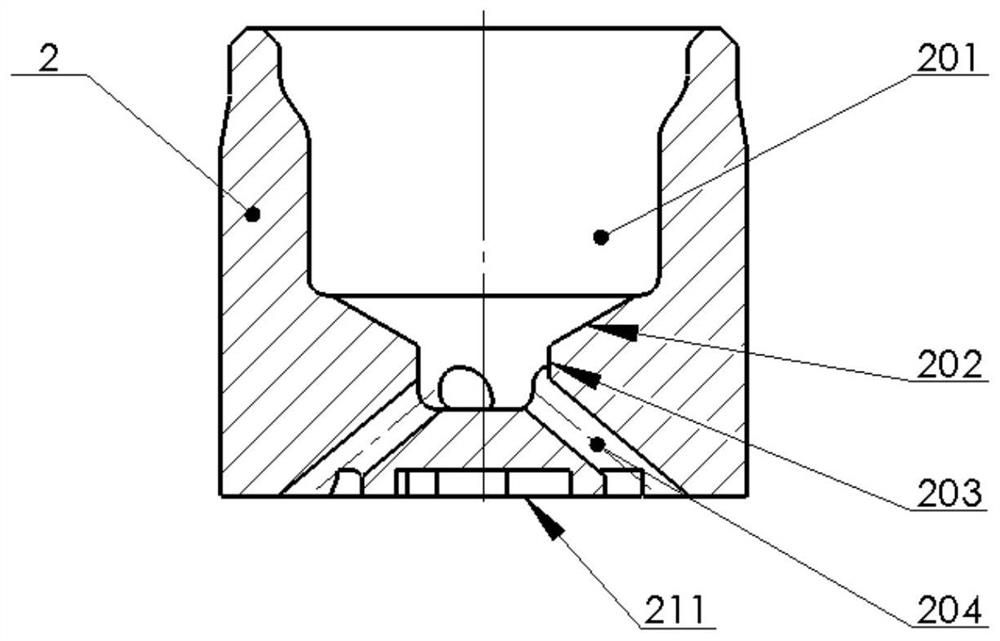

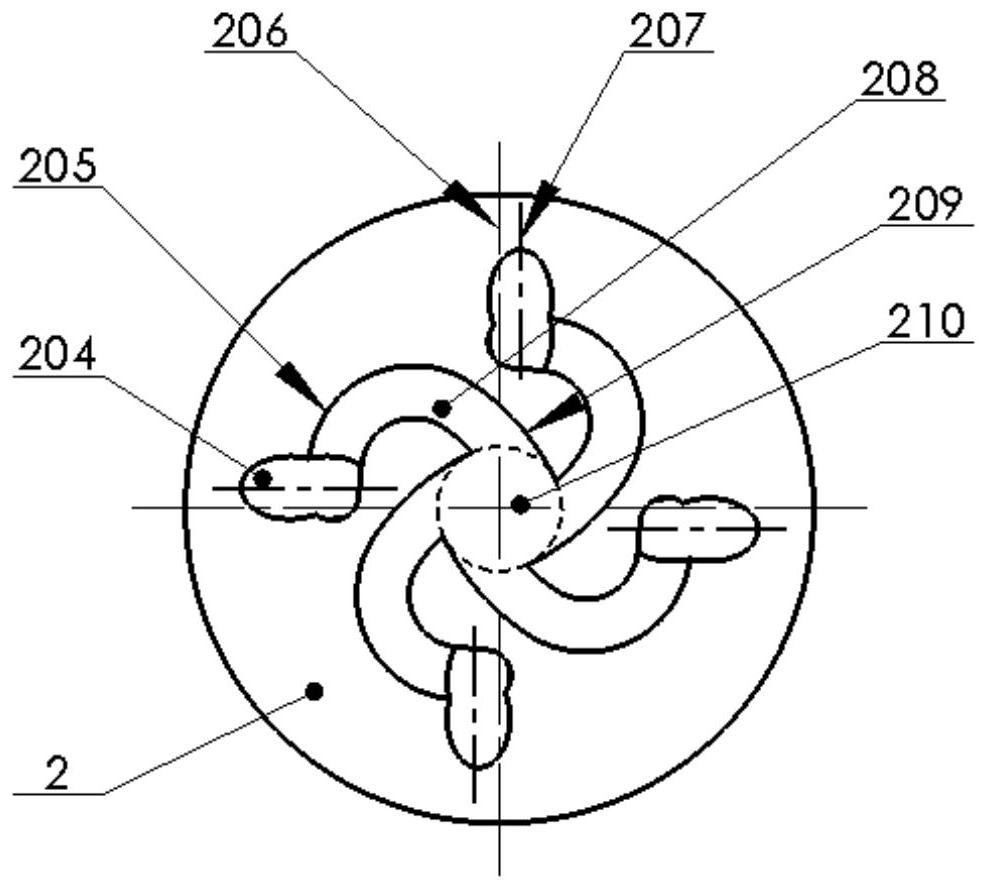

[0032] The valve seat 2 is fixed at the lower end of the inner hole 402 of the nozzle body 4 by laser welding. See especially figure 2 and image 3 , The valve seat 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com