Inverse gravity filling forming device of large-size complex amorphous alloy component

An amorphous alloy and anti-gravity technology, which is applied in the field of anti-gravity filling and forming devices for large-scale and complex amorphous alloy components, can solve problems such as high viscosity, low flow performance, and difficulty in filling complete components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

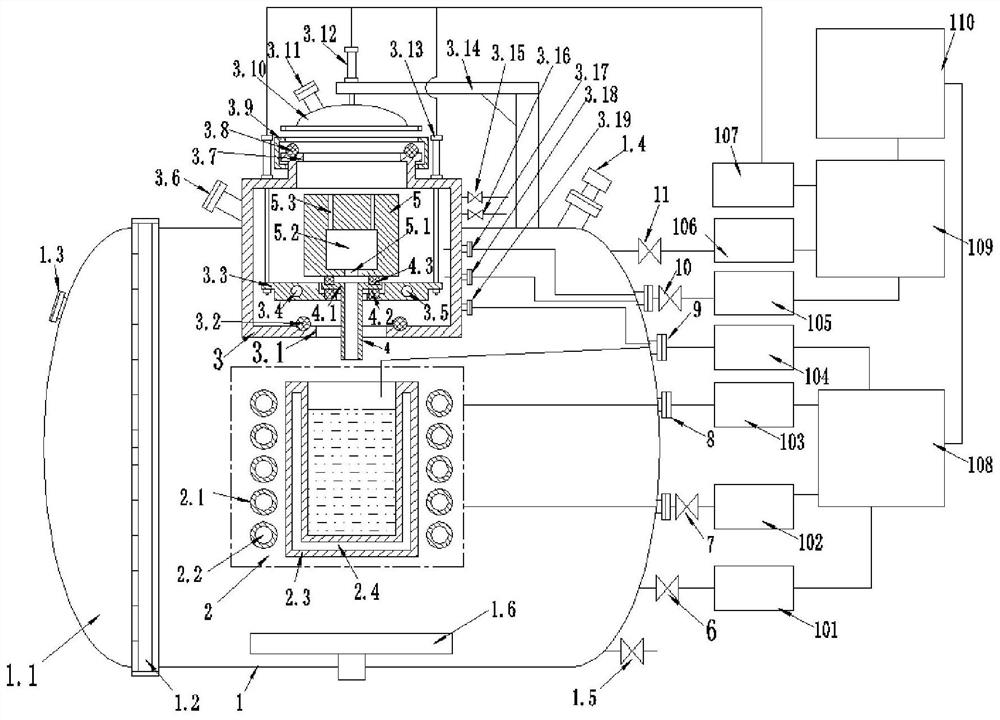

[0041] Specific implementation mode two: combination Figure 1-Figure 6 This embodiment is described. The large-scale and complex amorphous alloy component described in this embodiment is an anti-gravity filling and forming device. The melting chamber includes a melting chamber shell 1, a melting chamber door 1.1, a melting chamber locking ring assembly 1.2, and a melting chamber observation window 1.3 , The smelting cabin can adjust the camera 1.4 and the smelting cabin exhaust valve 1.5; the smelting cabin shell 1 is a cylindrical shell with one end open, the axis direction of the smelting cabin shell 1 is set horizontally, and the smelting cabin door 1.1 is locked through the smelting cabin The sealing cover of the ring assembly 1.2 is installed on the opening end of the smelting cabin shell 1, the smelting cabin observation window 1.3 is installed on the smelting cabin door 1.1, the smelting cabin adjustable camera 1.4 is installed on the top seal of the smelting cabin shel...

specific Embodiment approach 3

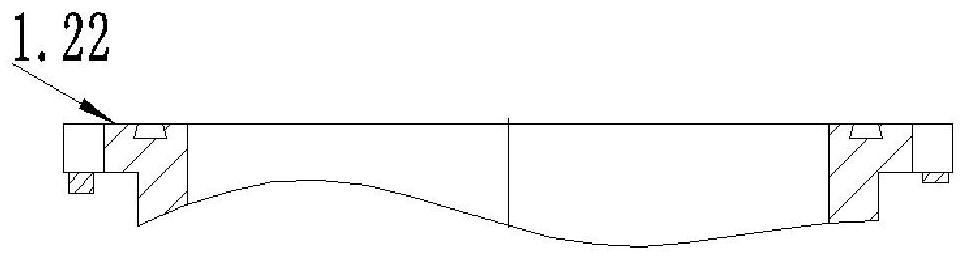

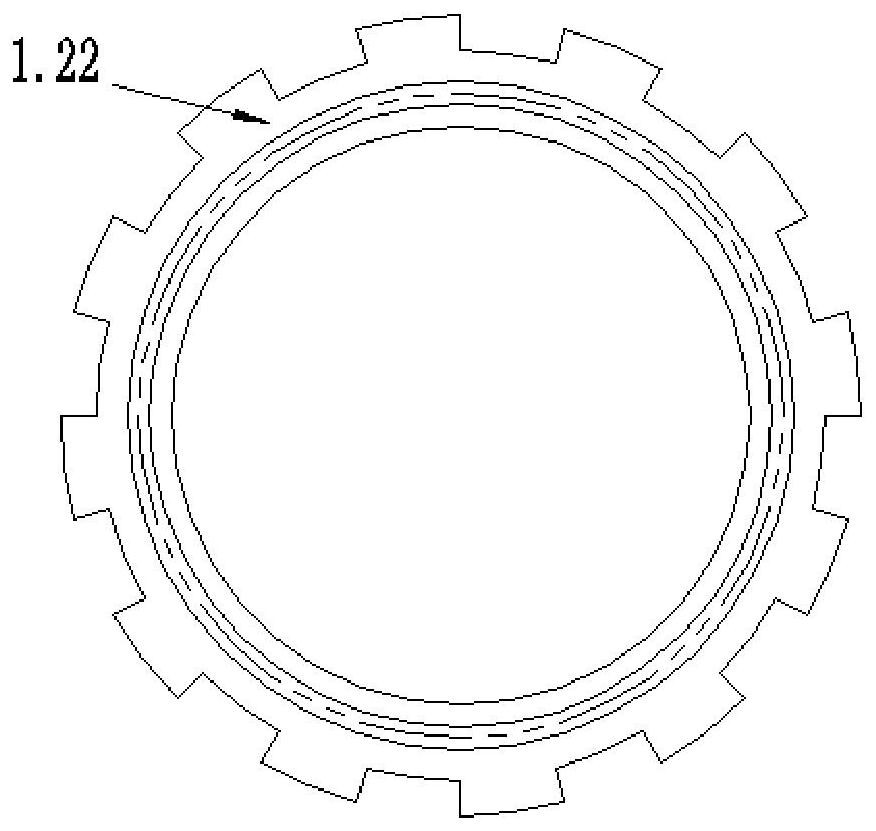

[0044] Specific implementation mode three: combination Figure 1-Figure 6 Describe this embodiment, the reverse gravity filling and forming device for large-scale complex amorphous alloy components described in this embodiment, the smelting cabin locking ring assembly 1.2 includes a smelting cabin locking ring 1.21, two locking flanges 1.22 and two locking Oil cylinder 1.23, a locking flange 1.22 is provided with sawtooth-shaped protrusions evenly distributed along the radial direction, the melting cabin locking ring 1.21 is an annular body, and the inner side wall of the annular body is processed with annular grooves in the radial direction, and the melting cabin locking ring 1.21 The side wall on one side is processed with a zigzag groove matching each zigzag protrusion on the locking flange 1.22, and another locking flange 1.22 is fixedly installed on the opening end of the melting cabin shell 1, and the melting cabin door 1.1 There is a locking flange 1.22 with saw-tooth-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com