Bipolar electrode, preparation method thereof and wastewater treatment system

A bipolar electrode and anode technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve redox synergy, insufficient mass transfer efficiency, and dehalogenation of pollutants Problems such as poor degradation effect can be achieved to reduce material impedance and charge transport energy barrier, improve mass transfer efficiency and catalyst activity, and solve the effects of mass transfer limitation and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

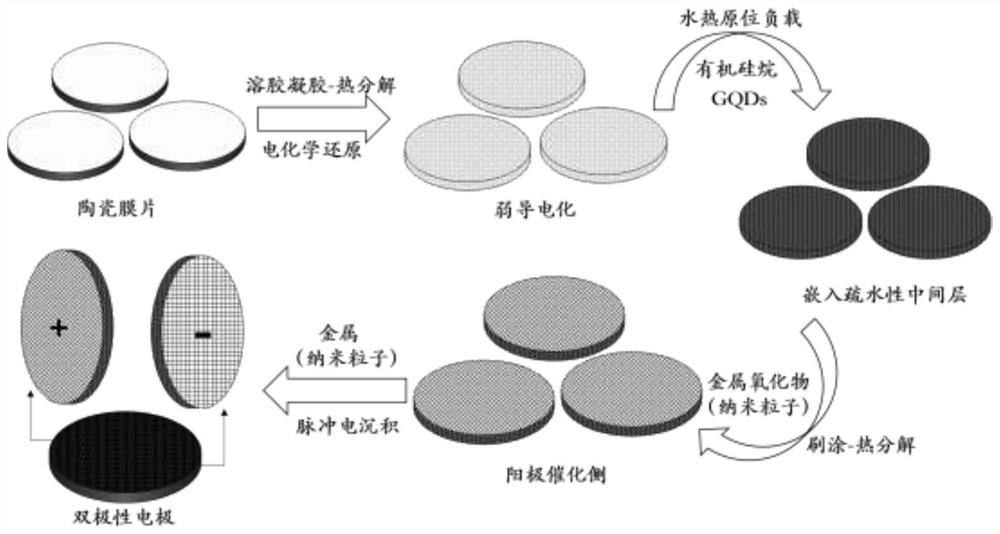

[0030] A method for preparing a bipolar electrode, comprising: performing weak electro-chemical modification on a ceramic film to obtain a matrix; performing hydrothermal synthesis-hydrophobic treatment on the matrix, embedding GQDs in its skeleton, and forming an intermediate layer on the surface of the matrix; Metal oxides and metals are respectively loaded on both sides of the layer, and an anode catalyst layer and a cathode catalyst layer are formed on both sides of the middle layer.

[0031] Specifically, step 1, first place the ceramic membrane in deionized water to ultrasonically clean it for 5-15 minutes, then keep it in an acidic solution at 98°C for 1-2h, then rinse it with deionized water until it is neutral, and then clean it at 90-105°C Drying under the sun; a titanium oxide layer is formed on the surface of the ceramic membrane by immersion-thermal decomposition method, wherein the composition of the immersion solution includes: tetrabutyl titanate with a volume f...

Embodiment 1

[0038] Step 1. Select Al with a diameter of 3cm, a thickness of 2.5mm, and an average pore diameter of 3μm 2 o 3 For the ceramic membrane, first place the ceramic membrane in deionized water and ultrasonically clean it for 15 minutes, then keep it in an acidic solution with a pH of 2 at 98°C for 2h, then rinse it with deionized water until neutral, and then dry it at 105°C. A titanium oxide layer is formed on the surface of the ceramic membrane by immersion-thermal decomposition method, wherein the immersion liquid composition includes: 80% tetrabutyl titanate by volume fraction, 20% ethanol by volume fraction and 0.1mol / L HNO 3 , the immersion time is 5min, and after taking it out, it is dried at a temperature of 105°C. After repeating immersion-drying 3 times, it is calcined at a calcination temperature of 500°C for 15min. The ceramic membrane loaded with titanium oxide is used as the cathode, and the graphite is used as the anode, and the 10mA / cm 2 Electrochemical reducti...

Embodiment 2

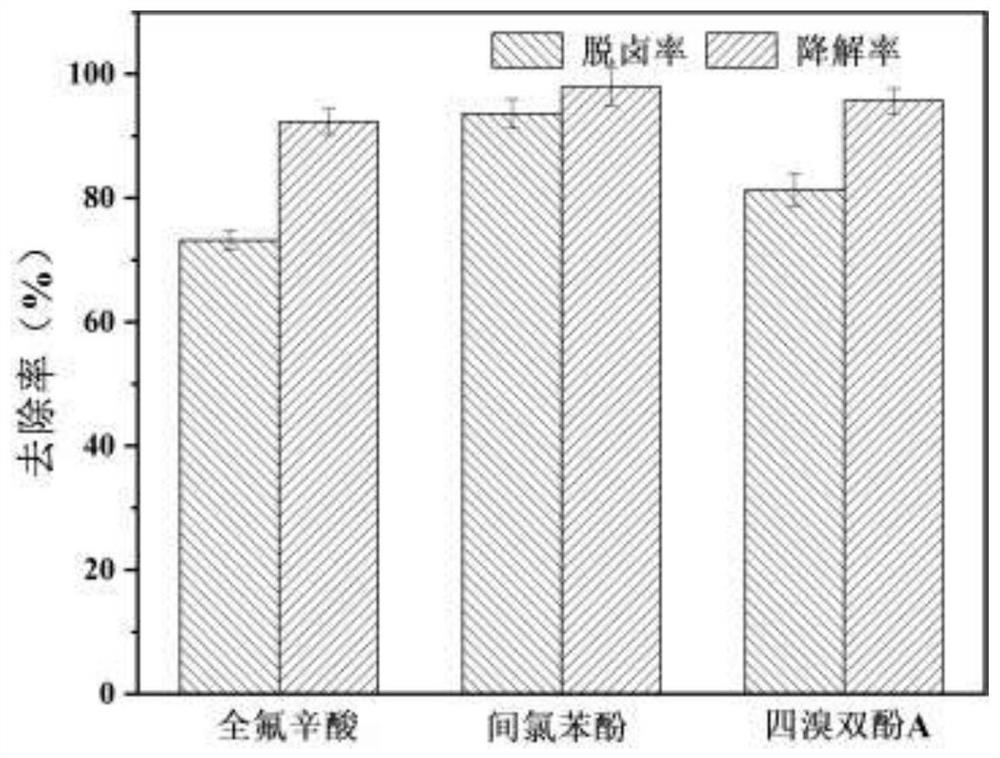

[0042] Sb-SnO 2 @Al 2 o 3 / GQDs@Pd-Fe bipolar electrode is the core, and the three typical halogenated pollutants simulated wastewater of perfluorooctanoic acid, m-chlorophenol and tetrabromobisphenol A are treated to evaluate their dehalogenation degradation effect. The specific processing method is as follows:

[0043] (1) Sb-SnO 2 @Al 2 o 3 / GQDs@Pd-Fe bipolar electrode 1 is installed in the electrolytic component 1, and the structure is as follows figure 2 The flow-through electrocatalytic wastewater treatment system shown;

[0044] (2) Prepare 1mg / L perfluorooctanoic acid solution, m-chlorophenol solution and tetrabromobisphenol solution respectively, with deionized water and 5mmol / L Na 2 SO 4 as solvent and supporting electrolyte respectively;

[0045] (3) Set the power supply 5 to output continuous DC power supply mode, the applied voltage is 3.0V, the set flow rate of the water pump is 5mL / min, the waste water in the waste water pool 3 enters the electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com