Alloying method for inducing icosahedron quasicrystal phase to be subjected to in-situ synthesis to reinforce cast aluminum-lithium alloy

An in-situ self-generated and icosahedral technology, applied in the field of in-situ self-generated and strengthened cast Al-Li alloys induced by quasi-crystalline phases, can solve the problems of aggravated coplanar slip tendency and decreased strength and toughness of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

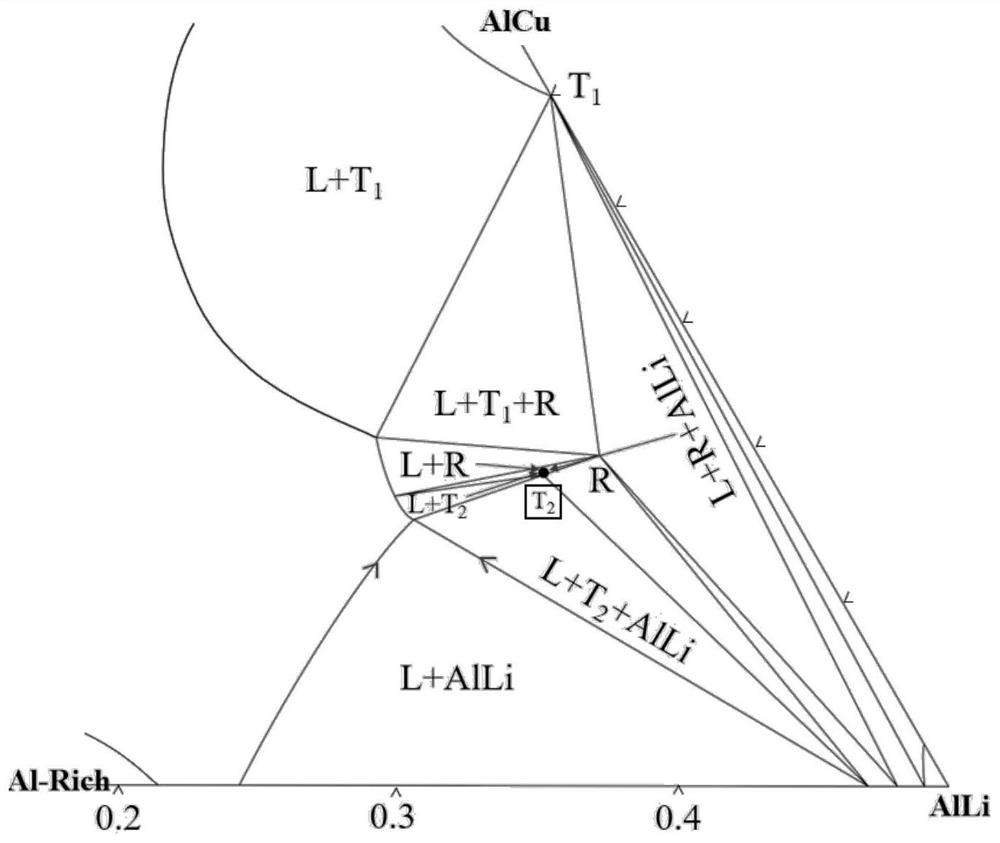

[0031] Specific implementation mode 1: This implementation mode is an alloying method for in situ authigenic casting aluminum-lithium alloy induced by icosahedral quasi-crystal phase, which is specifically carried out according to the following steps:

[0032] 1. Select pure aluminum, pure magnesium, pure lithium particles, Al-50Cu master alloy, Al-4Zr master alloy and aluminum-based master alloy containing alloying elements, and then remove the surface oxide scale and surface layer from the above-mentioned selected raw materials;

[0033] Wrap pure magnesium and pure lithium particles with aluminum foil;

[0034] The aluminum-based master alloy containing alloying elements is an Al-10Ni master alloy, and the finally prepared aluminum-lithium alloy is composed of: 1.8% to 3.2% Li, 0.5% to 2% Cu, 0.5% %~1.8% Mg, 0.04%~0.21% Zr, 0.2%~0.95% Ni, and the rest is Al;

[0035]The aluminum-based master alloy containing alloying elements can also be an Al-4V master alloy, and the fina...

specific Embodiment approach 2

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the aluminum-based master alloy containing alloying elements described in step 1 is an Al-10Ni master alloy, and the final prepared aluminum-lithium alloy is divided by mass The array is: 2.51% Li, 1.11% Cu, 1.38% Mg, 0.21% Zr, 0.24% Ni, and the rest is Al. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum-based master alloy containing alloying elements described in step 1 is an Al-10Ni master alloy, and the aluminum-lithium alloy finally prepared is as follows: The mass fraction composition is: 2.35% Li, 0.96% Cu, 1.22% Mg, 0.19% Zr, 0.44% Ni, and the rest is Al. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com