A kind of polyurethane/cotton cellulose composite aerogel insole and preparation method thereof

A technology of composite airgel and cotton cellulose, which is applied in the direction of insoles, footwear, clothing, etc., to achieve the effects of expanding application fields, easy promotion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

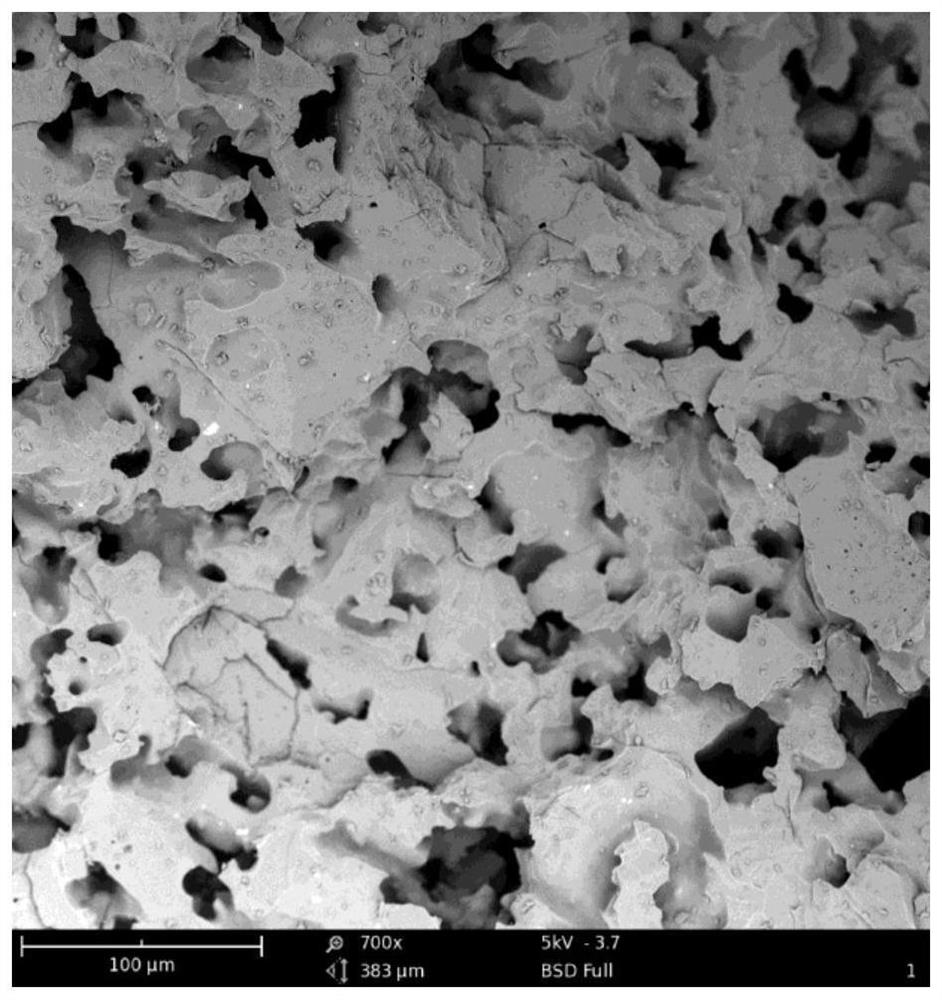

Image

Examples

Embodiment 1

[0026] In this embodiment, a polyurethane / cotton cellulose composite aerogel insole is prepared by the following method, including the following steps:

[0027] (1) Preparation of water-based polyurethane: add 0.75mol polyethylene glycol with a molecular weight of 2000 to a three-necked flask, vacuumize at 93°C for 1.5h to remove moisture; cool to 70°C, add 0.225mol toluene diisocyanate to react , the reaction time is 1.5h; refer to the method of HG / T2409-1992 to determine the content of NCO, add 0.02mol dimethylol propionic acid to carry out chain extension reaction for 0.75h; cool down to 5 ℃, add dissolved 3% sodium bisulfite A mixed solution of 80 mL of isopropanol and 200 mL of water was stirred at a high speed for 0.75 h; after the reaction, the pH value was adjusted to 3.5 to obtain an aqueous polyurethane emulsion;

[0028] (2) Preparation of cotton cellulose solution: Dissolve 20g waste cotton fabric in 150mL sodium hydroxide-urea-water mixed solution at -7°C, the mas...

Embodiment 2

[0032] In this embodiment, a polyurethane / cotton cellulose composite aerogel insole is prepared by the following method, including the following steps:

[0033] (1) Preparation of water-based polyurethane: 0.5 mol of polyethylene glycol with a molecular weight of 2000 was added to a three-necked flask, and vacuumed at 90 ° C for 1 h to remove moisture; cooled to 60 ° C, 0.15 mol of toluene diisocyanate was added to react, The reaction time is 1h; refer to the method of HG / T2409-1992 to measure the content of NCO, add 0.01mol dimethylolpropionic acid to carry out chain extension reaction for 0.5h; cool down to 0°C, add 80mL isopropyl alcohol dissolved in 1% sodium bisulfite A mixed solution of propanol and 160 mL of water was stirred at high speed for 0.5 h; after the reaction, the pH value was adjusted to 3 to obtain an aqueous polyurethane emulsion;

[0034] (2) Preparation of cotton cellulose solution: Dissolve 20g waste cotton fabric in 150mL sodium hydroxide-urea-water mix...

Embodiment 3

[0038] In this embodiment, a polyurethane / cotton cellulose composite aerogel insole is prepared by the following method, including the following steps:

[0039] (1) Preparation of water-based polyurethane: 1 mol of polyethylene glycol with a molecular weight of 2000 was added to a three-necked flask, and vacuumed at 95 °C for 2 h to remove moisture; cooled to 80 °C, 0.3 mol of toluene diisocyanate was added to react. The time is 2h; refer to the method of HG / T2409-1992 to measure the content of NCO, add 0.03mol dimethylolpropionic acid to carry out chain extension reaction for 1h; cool down to 8 ℃, add 150mL of isopropanol dissolved with 5% sodium bisulfite and A mixed solution of 450 mL of water was stirred at high speed for 1 h; after the reaction, the pH value was adjusted to 4 to obtain an aqueous polyurethane emulsion;

[0040] (2) Preparation of cotton cellulose solution: Dissolve 20g waste cotton fabric in 150mL sodium hydroxide-urea-water mixed solution at -10°C, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com