Quenching tower salt ash softening agent in rotary kiln incineration process and application method

An application method, the technology of quenching tower, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of limited operating space, low efficiency, poor lighting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

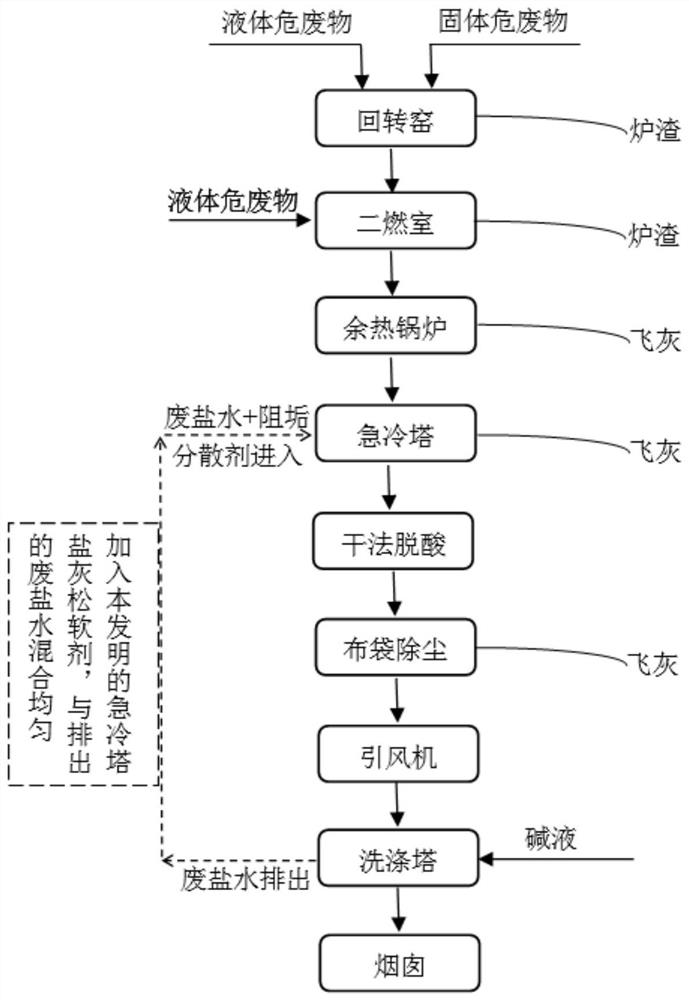

[0026] In the comprehensive hazardous waste disposal plant, when the waste brine is reused in the incineration quench tower, because the waste brine contains a large amount of soluble inorganic salts, a large amount of agglomerated ash will be produced with the evaporation of water under high temperature conditions, resulting in hazardous waste Disposal enterprises often need to shut down furnaces and production for manual cleaning, which affects the production efficiency and hazardous waste treatment capacity of enterprises.

[0027] experiment method:

[0028] In order to simulate the temperature, scale sample and brine of the on-site quench tower, the test method is designed:

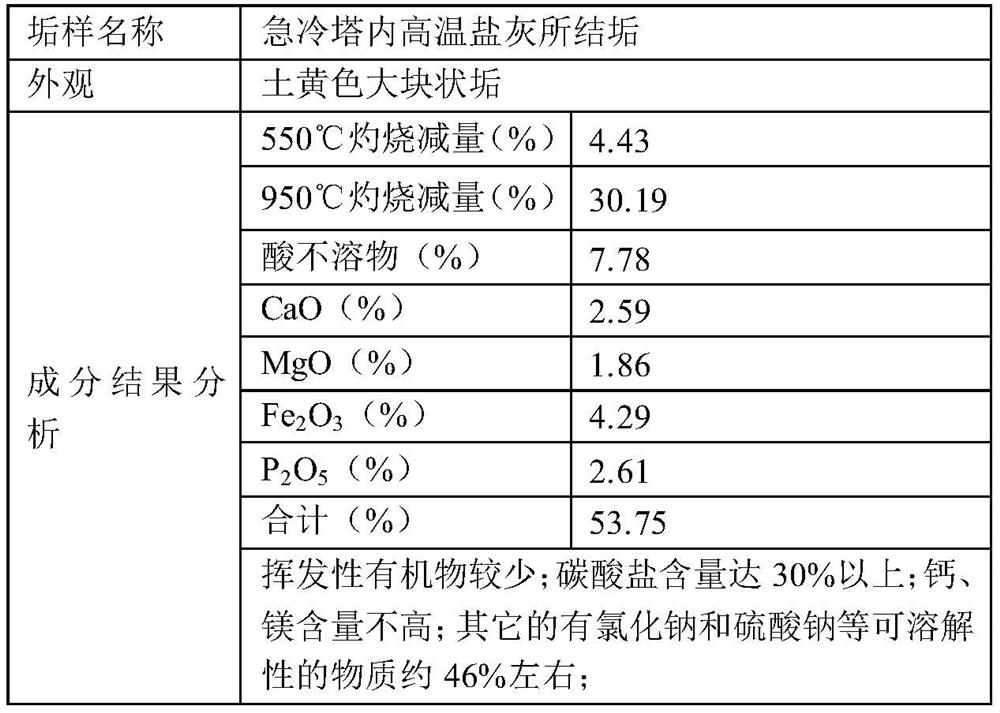

[0029] A. Scale sample: Take the scale sample from the lower part of the on-site quench tower, and do scale sample analysis (see the data in Table 1), grind the scale sample into fine powder, and use it for preparing the test solution. Add 5-10% to the test sample.

Embodiment 2

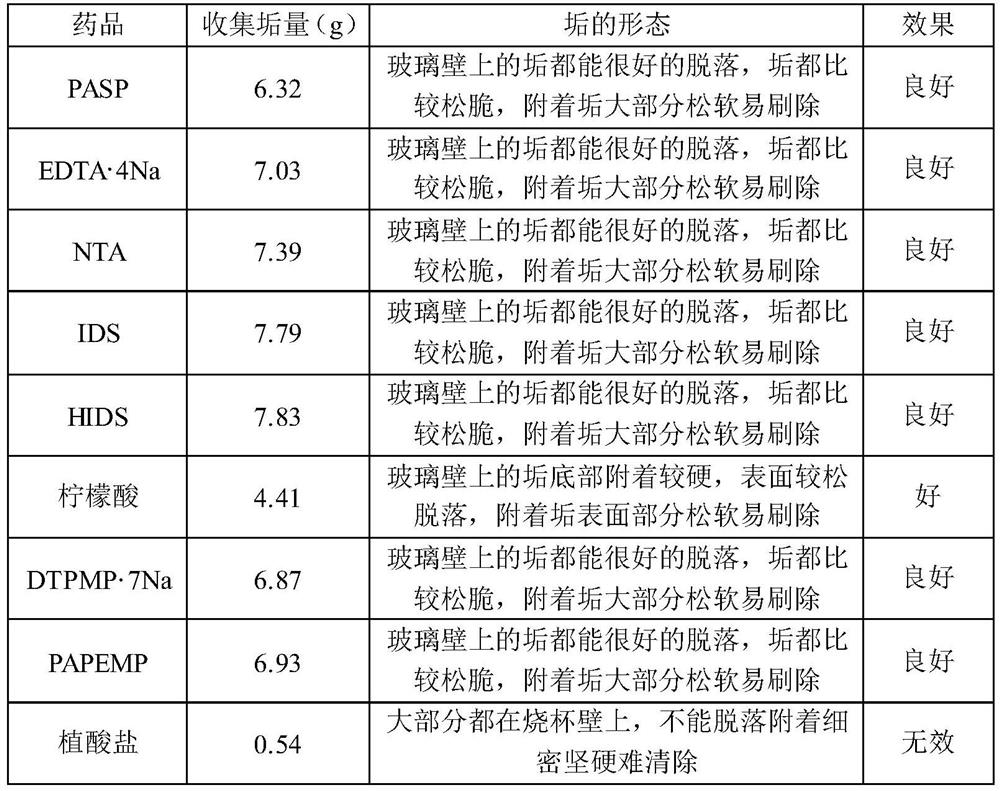

[0046] The medicine in Table 2 is carried out compatibility test, and concrete formula is as follows:

[0047] ①Compatibility test 1 formula: PASP 20%, EDTA 4Na 5%, NTA 10%, HIDS 20%, citric acid 10%, DTPMP 7Na 10%, PAPEMP 10%, phytate 3%, ferrocyanide Potassium 3%, Isovitamin C 2%, Sodium Hydroxide 7%;

[0048] ②Compatibility test 2 formula: PASP 15%, EDTA 4Na 10%, NTA 20%, HIDS 6%, citric acid 10%, DTPMP 7Na 12%, PAPEMP 8%, phytate 4%, ferrocyanide Potassium 5%, Isovitamin C 3%, Sodium Hydroxide 7%;

[0049] ③Compatibility test 3 formula: EDTA·4Na 10%, ATMP·4Na 25%, PAAS 25%, citric acid 10%, DTPMP·7Na 12%, PAPEMP 8%, phytate 4%, sodium hydroxide 6%;

[0050] ④ Formula of compatibility test 4: HEDP·4Na 25%, MA-AA·Na 25%, DTPMP·7Na 10%, PAPEMP 10%, EDTA·4Na 5%, citric acid 10%, potassium ferrocyanide 5%, Isovitamin C 3%, sodium hydroxide 7%.

[0051] The specific results are shown in Table 3.

[0052] Table 3 Effects after drug compatibility

[0053]

[0054]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com