Preparation and application of durable high-flux emulsion separation membrane material

An emulsion separation, high-throughput technology, applied in the field of materials, to achieve high-efficiency and high-throughput separation, good organic solvent resistance, and overcome the effects of low separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

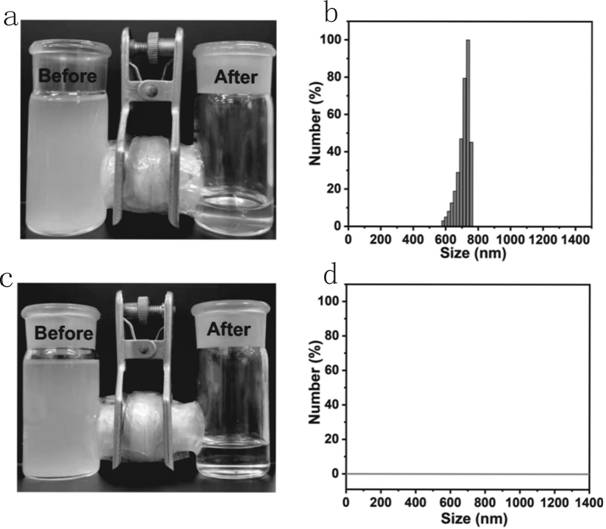

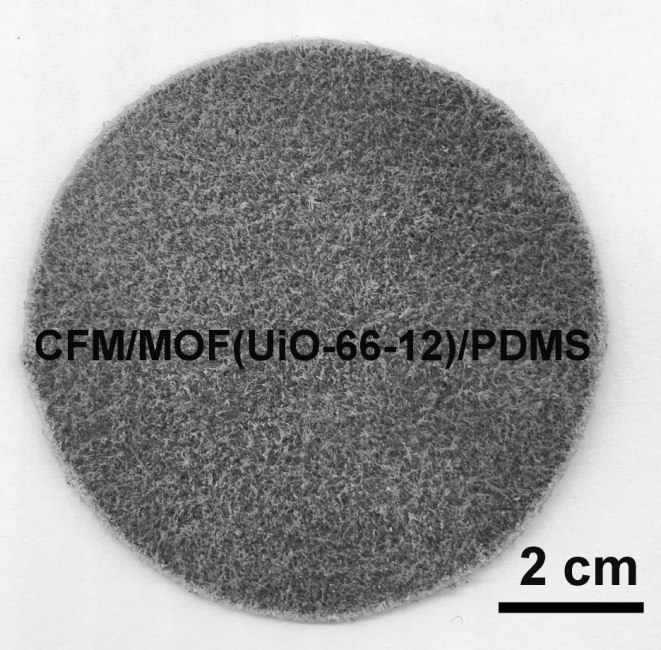

[0058] (1) Preparation of CFM / MOF(UiO-66-12) / PDMS membrane:

[0059] 0.318 g of zirconium tetrachloride was ultrasonically dissolved in 108 mL of N, N-dimethylformamide, then 0.228 g of terephthalic acid was added, and the above mixed solution was reacted in a reactor at 120 °C for 24 h, and then cooled to room temperature , after centrifugation at 8000 rpm and vacuum drying at 60°C, UiO-66NPs were obtained; 20 mg UiO-66NPs were dispersed in 100 mL deionized water, and then the Soak CFM in UiO-66NPs suspension and sonicate for 1.0h, take it out and dry at 60°C to obtain CFM loaded with UiO-66NPs seed crystals; mix 70 mL N, N-dimethylformamide, 0.71 mL 70wt% The zirconium n-propoxide solution was mixed with 40 mL glacial acetic acid, then 750 mg terephthalic acid was added, and the CFM loaded with UiO-66NPs seed crystals was immersed in the above mixed solution for 12 h, and then dried to obtain CFM / MOF ( UiO-66) membrane; the CFM / MOF (UiO-66) membrane was placed in 30 mL of 5...

Embodiment 2

[0073] (1) Preparation of CFM / MOF(UiO-66-15) / PDMS membrane:

[0074] 0.318 g of zirconium tetrachloride was ultrasonically dissolved in 108 mL of N, N-dimethylformamide, then 0.228 g of terephthalic acid was added, and the above mixed solution was reacted in a 120ºC reactor for 24 h, and then cooled to room temperature. After centrifugation at 8000 rpm and vacuum drying at 60 °C, UiO-66NPs were obtained; 20 mg UiO-66NPs were dispersed in 100 mL deionized water, and then CFM with a diameter of 8.0 cm and a thickness of 1.5-1.8 mm Soaked in UiO-66NPs suspension and sonicated for 1.0h, took it out and dried at 60°C to obtain CFM loaded with UiO-66NPs seeds; 70 mL N, N-dimethylformamide, 0.71 mL 70wt% normal The zirconium propoxide solution was mixed with 40 mL of glacial acetic acid, then 750 mg of terephthalic acid was added, and the CFM loaded with UiO-66NPs seed crystals was immersed in the above mixed solution for 15 h, and the CFM / MOF (UiO -66) membrane; place the CFM / MOF(U...

Embodiment 3

[0081] (1) Preparation of CFM / MOF(UiO-66-18) / PDMS membrane:

[0082] 0.318 g of zirconium tetrachloride was ultrasonically dissolved in 108 mL of N, N-dimethylformamide, then 0.228 g of terephthalic acid was added, and the above mixed solution was reacted in a reactor at 120 °C for 24 h, and then cooled to room temperature , after centrifugation at 8000 rpm and vacuum drying at 60°C, UiO-66NPs were obtained; 20 mg UiO-66NPs were dispersed in 100 mL deionized water, and then the Soak CFM in UiO-66NPs suspension and sonicate for 1.0h, take it out and dry at 60°C to obtain CFM loaded with UiO-66NPs seed crystals; mix 70 mL N, N-dimethylformamide, 0.71 mL 70wt% The zirconium n-propoxide solution was mixed with 40 mL glacial acetic acid, then 750 mg terephthalic acid was added, and the CFM loaded with UiO-66NPs seed crystals was immersed in the above mixed solution for 18 h, and then dried to obtain CFM / MOF ( UiO-66) membrane; the CFM / MOF (UiO-66) membrane was placed in 30 mL of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com