Crystal face modulated low-platinum alloy catalyst and preparation method and application thereof in fuel cell

A composite catalyst, platinum alloy technology, applied in battery electrodes, circuits, electrical components, etc., to achieve strong operability, promote large-scale commercial applications, and improve oxygen reduction electrocatalytic activity and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

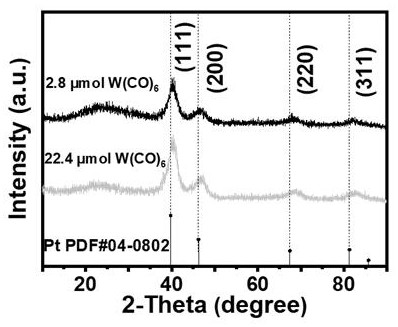

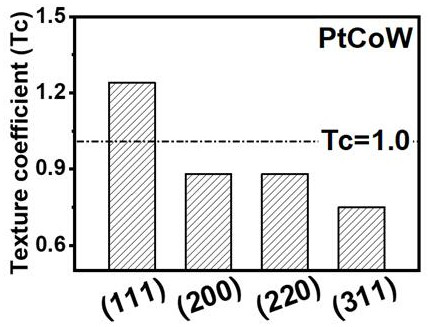

[0036] When the reaction system is ethylene glycol and deionized water, a platinum-cobalt-tungsten alloy nanoparticle composite catalyst with preferred crystal plane orientation is prepared, and the steps are as follows:

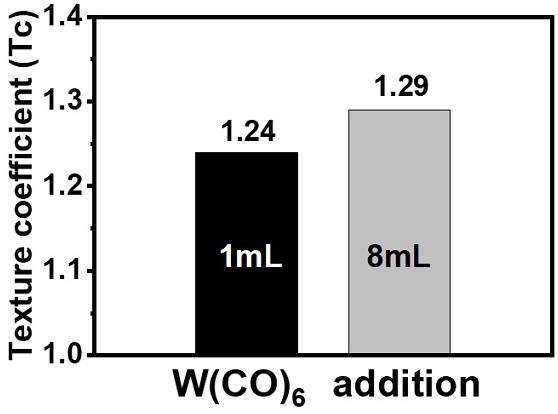

[0037] (1) Take 14.2 mL of ethylene glycol and 23.7 mL of deionized water, take a certain amount of commercial carbon black powder and add it to the above solution, ultrasonicate for 60 min, add 9.3 mL of 0.01 M chloroplatinic acid ethylene glycol solution and 0.31 mL of 0.1 M cobalt chloride ethylene glycol solution and 1 mL of DMF solution with a concentration of 2.8 mM tungsten hexacarbonyl, and adjust the pH of the solution to 10 with NaOH solution to obtain a suspension;

[0038] (2) Put the suspension obtained in step (1) into a reaction kettle, place it in a vacuum drying oven at 200°C for reduction reaction, and react at this temperature for 3 h. After the reaction was finished, black slurry was obtained;

[0039] (3) Suction filter the black slurry...

Embodiment 2

[0042] Preparation of Platinum-Cobalt-Wungsten Alloy Nanoparticle Composite Catalysts with Preferential Orientation of Crystal Faces When the Reaction System Is Ethylene Glycol and Deionized Water

[0043] (1) Take 14.2 mL of ethylene glycol and 23.7 mL of deionized water, take a certain amount of commercial carbon black powder and add it to the above solution, sonicate for 30 minutes, add 9.3 mL of 0.01 M chloroplatinic acid in ethylene glycol solution and 0.31 mL of 0.1 M cobalt chloride in ethylene glycol and 8 mL of 2.8 mM tungsten hexacarbonyl in DMF. And adjust the pH of the solution to 8 with NaOH solution to obtain a suspension;

[0044] (2) Put the suspension obtained in step (1) into a reaction kettle, place it in a vacuum drying oven at 160°C for reduction reaction, and react at this temperature for 5 h. After the reaction was finished, black slurry was obtained;

[0045] (3) Suction filter the black slurry obtained in step (2), wash with deionized water, and dry ...

Embodiment 3

[0048] When the reaction system is ethylene glycol and deionized water, a platinum-cobalt-molybdenum alloy nanoparticle composite catalyst with preferred crystal plane orientation is prepared, and the steps are as follows:

[0049] (1) Take 14.2 mL of ethylene glycol and 23.7 mL of deionized water, take a certain amount of commercial carbon black powder and add it to the above solution, ultrasonicate for 60 min, add 9.3 mL of 0.01 M chloroplatinic acid ethylene glycol solution and 0.31 mL of 0.1 M cobalt chloride ethylene glycol solution and 1 mL of DMF solution with a concentration of 2.8 mM molybdenum hexacarbonyl, and adjust the pH of the solution to 10 with NaOH solution to obtain a suspension;

[0050] (2) Put the suspension obtained in step (1) into a reaction kettle, place it in a vacuum drying oven at 210°C for reduction reaction, and react at this temperature for 3 h. After the reaction was finished, black slurry was obtained;

[0051] (3) Suction filter the black sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com