Acidic low-level radioactive waste liquid treatment method and system, and nuclear fuel post-treatment plant system

A treatment method and technology of a treatment system, which is applied in the field of reprocessing plant system, treatment method and system of acidic low-level radioactive waste liquid, and can solve problems such as limited purification effect, inability to change waste liquid, difficulty in meeting discharge requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

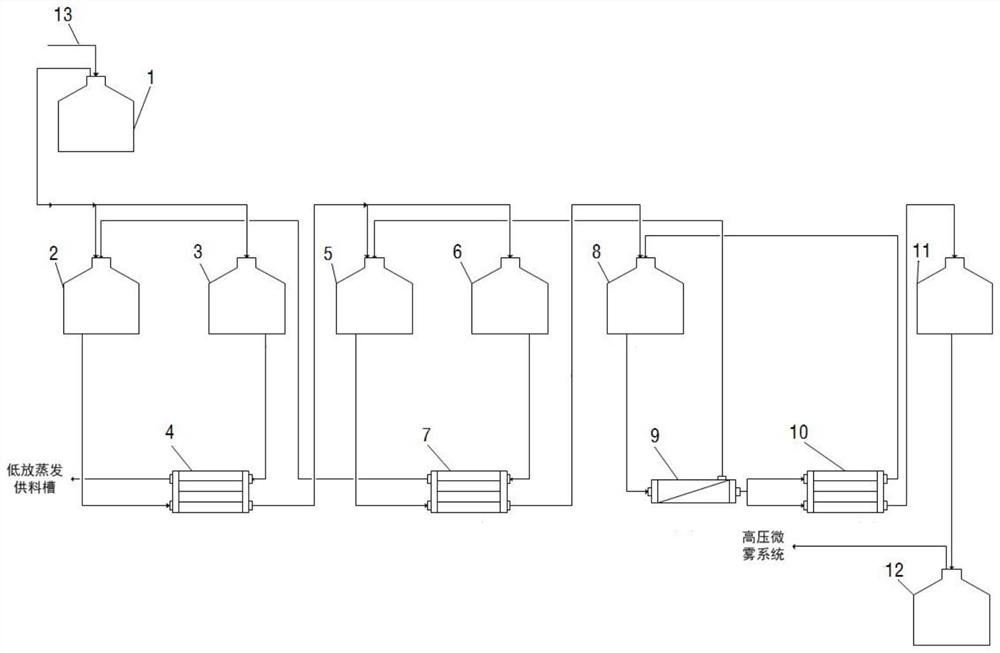

[0049] Such as figure 1 As shown, this embodiment discloses a treatment method for acidic low-level radioactive waste liquid, including:

[0050] The acidic low-level radioactive waste liquid is subjected to multi-stage acid separation treatment, and the concentrated liquid nitric acid is separated to obtain the light waste liquid;

[0051] Then, the thin waste liquid is subjected to multi-stage fine treatment to separate nuclides (such as cesium, strontium, etc.) to obtain a purified liquid.

[0052] This embodiment also discloses a type-selected treatment system for low-level radioactive waste liquid, including an acid treatment device and a fine treatment device, wherein:

[0053] Acid treatment device, which is used for multi-stage acid separation treatment of acidic low-level radioactive waste liquid, and separates concentrated liquid nitric acid to obtain light waste liquid;

[0054] The fine treatment device is connected with the acid treatment device, and is used to ...

Embodiment 2

[0057] This embodiment discloses a treatment method for acidic low-level radioactive waste liquid, including:

[0058] (1) The acidic low-level radioactive waste liquid is subjected to multi-stage acid separation treatment, and the concentrated liquid nitric acid is separated to obtain light waste liquid. Among them, the multi-stage acid separation treatment mainly adopts the electric drive membrane (electric drive membrane technology) technology, which includes The following steps: if figure 1 As shown, the acidic low-level waste liquid is first passed into the electrodialysis membrane stack 4 (the working principle of the electrodialysis membrane stack is: the anion and cation exchange membranes are alternately arranged between the positive and negative electrodes, and separated by a separator , under the action of an electric field, using the selective permeability of the ion-exchange membrane, the charged particles in the solution are separated by migration through the ion...

Embodiment 3

[0072] Such as figure 1 As shown, this embodiment discloses a treatment system for acidic low-level radioactive waste liquid, including an acid treatment device and a fine treatment device, wherein:

[0073] Acid treatment device, which is used for multi-stage acid separation treatment of acidic low-level radioactive waste liquid, and separates concentrated liquid nitric acid to obtain light waste liquid;

[0074] The fine treatment device is connected with the acid treatment device, and is used to receive the light waste liquid obtained after treatment by the acid treatment device, and separate nuclides such as cesium and strontium in the light waste liquid obtained above to obtain a purified liquid.

[0075] In some embodiments, the acid treatment device includes a primary acid separation unit and a secondary acid separation unit, wherein: the primary acid separation unit includes a primary acid separation membrane stack, and the primary acid separation membrane stack prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com