Fuel salt loop system and operation method

An operation method and salt circuit technology, which are applied in the fields of reactor fuel elements, greenhouse gas reduction, nuclear reactors, etc., can solve the problems of single-stack power increase of molten salt reactors and the complexity of the reactor body, so as to eliminate pump shutdown accidents, simplify design, improve Effects of Inherent Security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

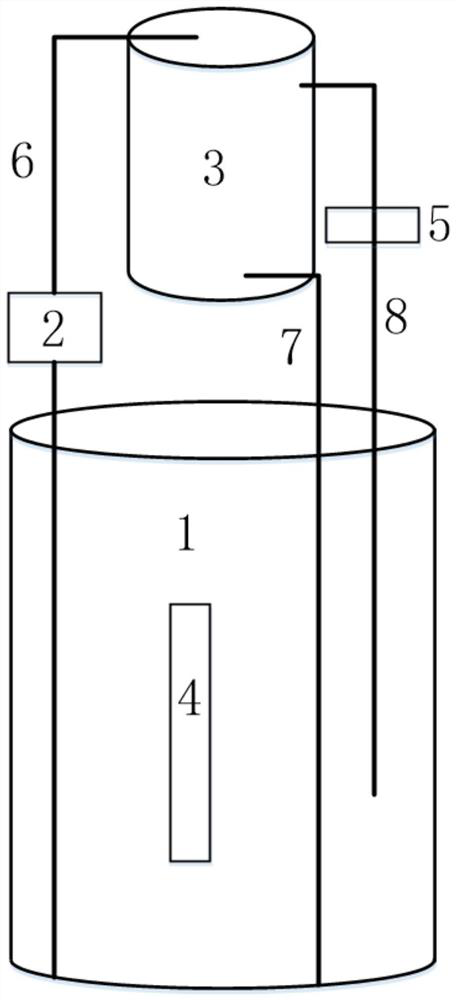

[0039] Such as figure 1As shown, the fuel salt loop system includes a fuel salt pool 1, a main pump 2, a stack container 3, a heat exchanger 4, a liquid level control valve 5, a stack container inlet pipe 6, a stack container outlet pipe 7, and a liquid level control pipe 8. The fuel salt flows among the fuel salt pool 1, the main pump 2, the stack container inlet pipe 6, the stack container outlet pipe 7, the liquid level control pipe 8, and the stack container 3, forming a fuel salt loop system. The fuel salt pool 1 is used to carry fuel salt and neutron poisons, the bottom of the stack container 3 is higher than the top of the fuel salt pool 1, the stack container inlet pipe 6 is arranged at the bottom of the stack container 3, and is provided with a main pump 2, and a stack container outlet pipe 7 It is arranged on the upper part of the stack container 3 and is provided with an outlet valve. The other end of the stack container inlet pipe 6 and the other end of the stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com