An integrated prefabricated drainage structure construction method for bridges

A construction method and construction technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of high construction design requirements of bridge drain pipes, inconsistent construction quality control on site, and no effective connection measures, so as to avoid main girder diseases , Excellent impact resistance, and the effect of increasing the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

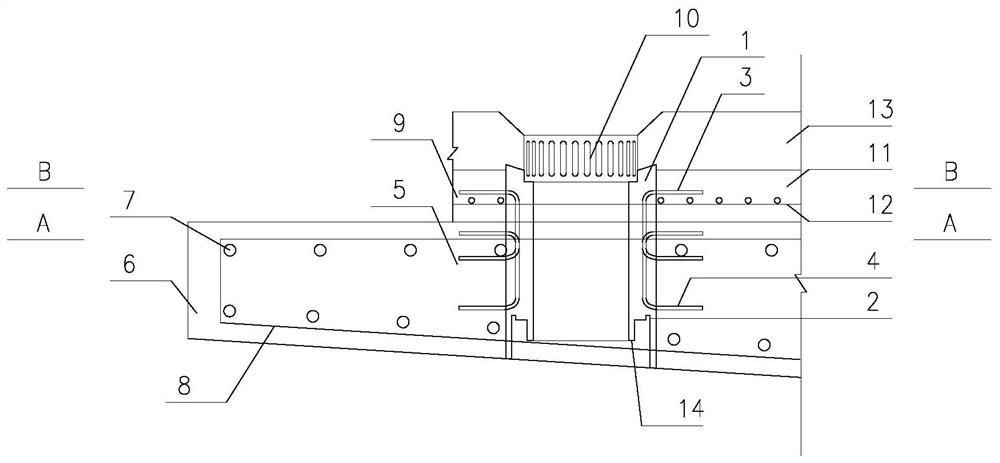

[0025] An integrated prefabricated drainage structure construction method for bridges, comprising the following steps:

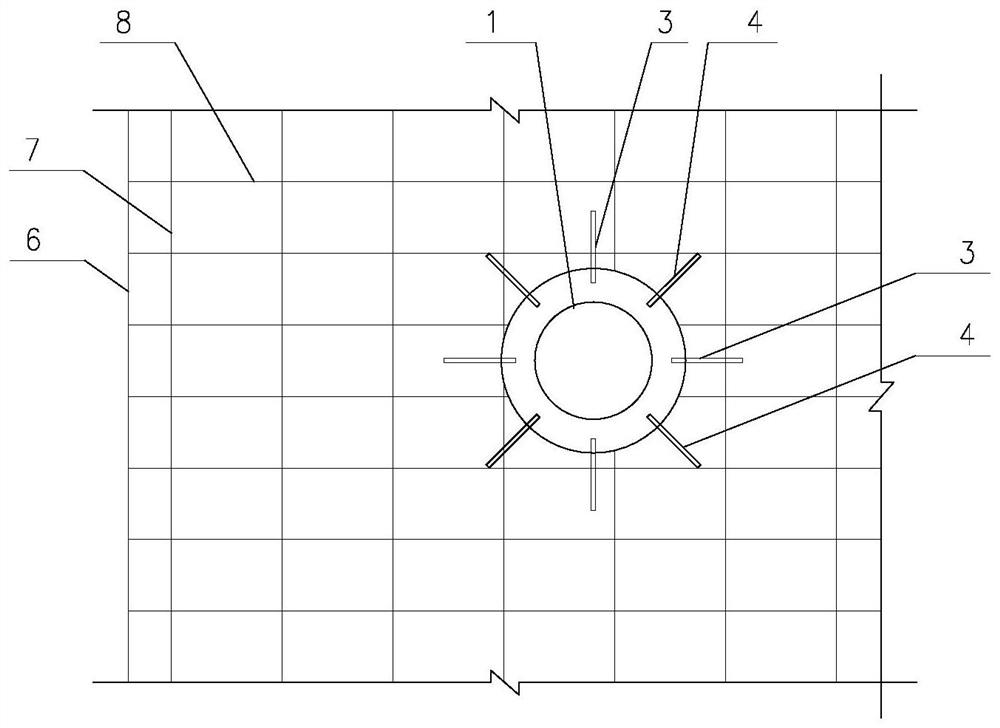

[0026] 1) Prefabricated drain hole drain pipe 1, poured with ultra-high performance concrete, set with dripping edge 2, drain pipe fixing device 14, first embedded connecting steel bar 4 and second embedded connecting steel bar 3, drain steel pipe 10 embedded In the prefabricated scupper drain pipe;

[0027] 2) After the main girder flange plate 6 template is installed and the main girder flange plate longitudinal bars 7 and main girder flange plate stirrups 8 are bound, install the prefabricated drain hole drain pipe 1, and connect the first pre-embedded connecting steel bar 4 with the main girder flange plate longitudinal bars 7 or the main beam flange plate stirrups 8 are connected, and then the main beam concrete is poured;

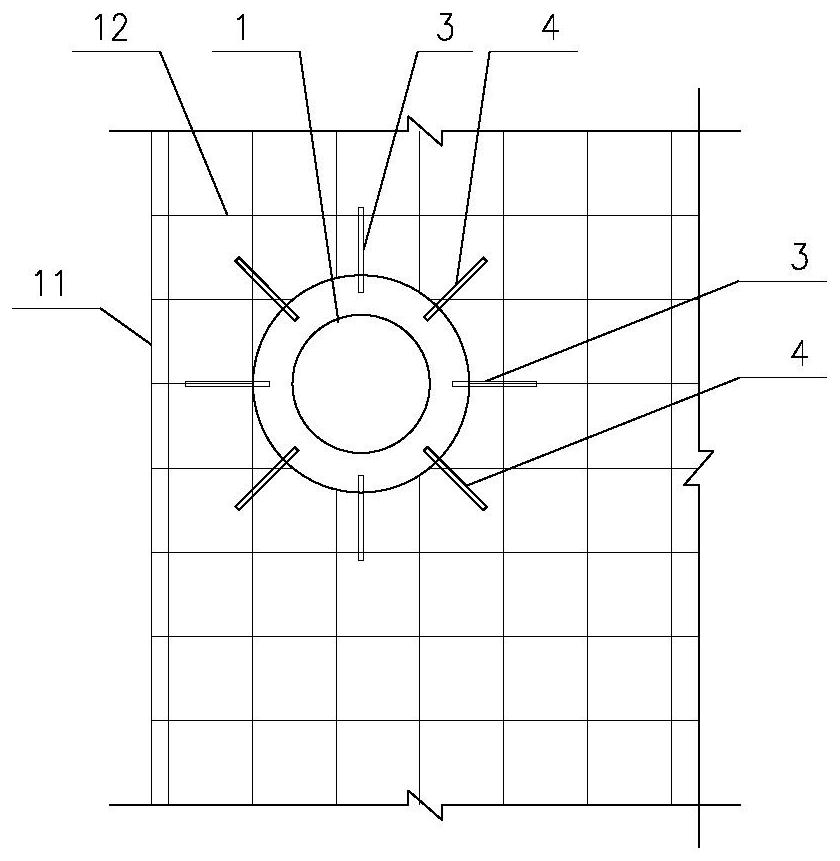

[0028] 3) Concrete bridge deck paving After the reinforcement mesh 12 is laid, the second pre-embedded connecting steel bar 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com