Annealing method in the production of medium and high voltage electronic aluminum foil for high-capacity and high-strength capacitors

An electronic aluminum foil, high-strength technology, applied in the direction of coating, metal rolling, anti-corrosion coating, etc., can solve the problems of shortening the production cycle, uneven casting structure, etc., and achieve the elimination of uneven casting, uniform grain size, avoid The effect of moisture residual oxidation

Active Publication Date: 2022-05-31

广西广投正润新材料科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

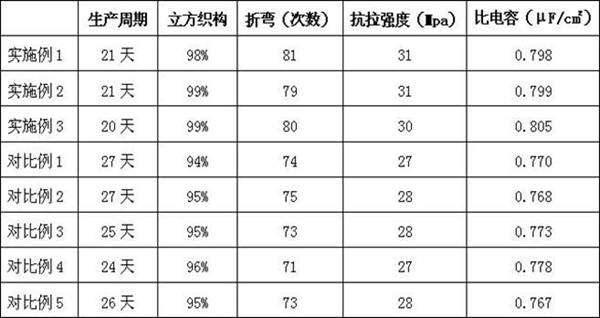

[0006] Aiming at the deficiencies in the prior art, the present invention provides an annealing method in the production of medium and high voltage electronic aluminum foils for high-capacity and high-strength capacitors, using a continuous air cushion furnace for homogenization and annealing for many times to improve the problem of uneven casting structure, thereby improving performance and cubic texture, to obtain a high-capacity high-strength high-voltage high-purity aluminum foil for capacitors, which not only improves the specific capacity, but also shortens the production cycle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0056] The step 1) described by the continuous air cushion furnace adopts the belt type to carry out intermediate annealing and the step 3) described by the continuous air cushion furnace.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an annealing method in the production of medium and high-voltage electronic aluminum foil for high-capacity and high-strength capacitors. The continuous air-cushion furnace adopts a belt type to perform intermediate annealing. The aluminum strip is heated evenly, and the heating time is controlled by the speed of the continuous air-cushion furnace. The time is stable and controllable, which ensures the consistency of grain recrystallization growth, the obtained structure is uniform, eliminates internal stress, and reduces the degree of work hardening of aluminum foil; the finished aluminum foil is annealed through a continuous air cushion furnace, and multi-zone different temperatures are used for annealing In this way, the recrystallization growth rate of the grains is controlled, ensuring that the non-cubic texture is transformed into a cubic texture, increasing the ratio of the cubic texture, and enriching trace elements on the surface to increase the corrosion porosity; Rapid cooling and winding to prevent surface damage caused by thermal adhesion.

Description

Annealing method in the production of medium and high voltage electronic aluminum foil for high capacity and high strength capacitors technical field The present invention relates to the technical field of high-voltage electronic aluminum foil processing, in particular to high-capacity high-strength capacitors with high Annealing methods in the production of piezo-electric foils. Background technique Miniaturization is the inevitable trend of the development of aluminum electrolytic capacitors, along with the rapid development of electrical and electronic industries, aluminum electrolytic capacitors Capacitors continue to develop towards high performance, miniaturization and integration, so it is necessary to improve the specific capacity of high-purity aluminum foil to meet the needs of aluminum electric To solve the demand for miniaturization of capacitors, it is also necessary to increase the output of pure aluminum foil to meet the increasing market demand. The a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F1/04C22F1/02C23G5/06B21B3/00B21B1/40C09D1/00C09D5/08

CPCC22F1/04C22F1/02C23G5/06B21B3/00B21B1/40C09D1/00C09D5/08B21B2003/001Y02E60/13

Inventor 胡传彬黄奎覃雪伍志铭李永春贾桂龙刘挺尹建平黄玉芳

Owner 广西广投正润新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com