A kind of gradient diamond/copper composite material and its preparation method

A composite material and diamond technology, applied in the field of gradient diamond/copper composite material and its preparation, can solve the problems of difficult bonding, low expansion coefficient and welding performance, high thermal conductivity, etc. High-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

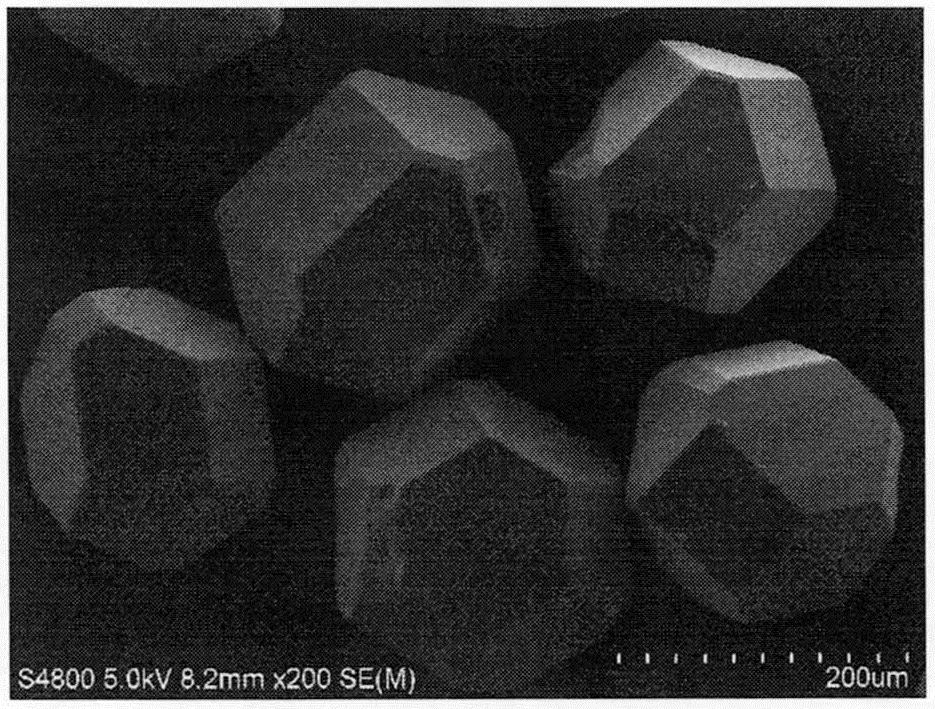

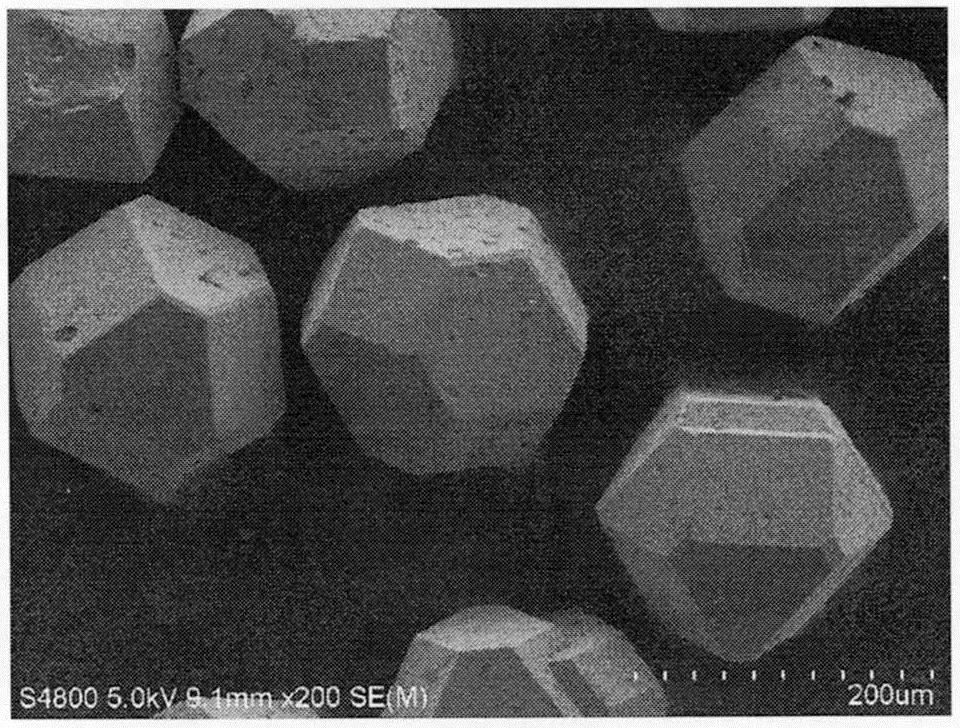

[0029] The preparation of tungsten-coated diamond particles on the surface, the specific process includes: put the diamond particles in ethanol and clean them with ultrasonic vibration for 30 minutes, take them out and wash them with deionized water until they are neutral, then put them in acetone and clean them with ultrasonic vibrations for 30 minutes, take them out and use them again. Wash with deionized water until neutral. Then put the cleaned diamond particles into 15% NaOH solution and boil for 10min, take it out and wash with deionized water until neutral, then put the diamond particles into 30% HNO 3 Boil in the solution for 30 minutes, take it out, wash it with deionized water until it is neutral, and dry it to obtain a surface-activated diamond. Put the pretreated diamond, high-purity tungsten powder, and tungsten trioxide mixed powder into a ball mill tank at a mass ratio of 1:1, and use a planetary ball mill mixer at a speed of 200r / min to rotate forward and rever...

Embodiment 2

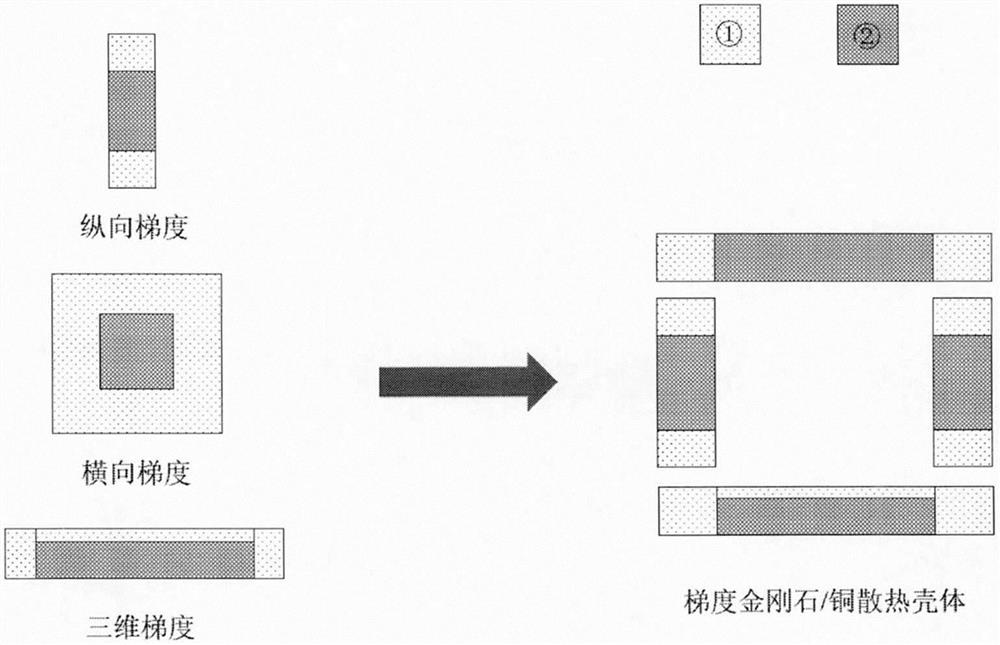

[0034] This embodiment is a gradient diamond / copper composite heat dissipation material. The preparation process is the same as that of Embodiment 1, the only difference is that the diamond in the composite material is distributed in a transverse gradient, and the gradient filling method is set in a high-strength graphite mold and the mold The tungsten wire mesh with the same shape and smaller size divides the mold into two areas in the lateral direction, and fills 10% and 50% of the designed amount of mixed powder with the volume fraction of diamond in the outer and inner parts respectively to realize the mixed powder transverse gradient packing. After molding process, get such as Figure 5 The laterally graded diamond / copper composite is shown.

Embodiment 3

[0036] This embodiment is a gradient diamond / copper composite heat dissipation material. The preparation process is the same as that of Embodiment 1. The only difference is that the diamond in the composite material is distributed in a three-dimensional gradient, that is, there are both horizontal and vertical gradients, and the gradient filling method is also Use both ways at the same time. After molding process, get such as Figure 6 The 3D gradient diamond / copper composite is shown.

[0037] According to the longitudinal and transverse gradient diamond / copper composite materials prepared in Examples 1, 2, and 3 of the present invention, after proper size adjustment, arrangement and combination, they can be directly welded as Figure 7 The gradient diamond / copper heat dissipation shell shown, pattern ① represents a lower diamond volume fraction, and pattern ② represents a higher diamond volume fraction; the bottom plate and cover plate of the shell are designed with a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com