Controllable porous calcium phosphate scaffold and preparation method thereof

A porous calcium phosphate and calcium phosphate technology, applied in the field of bone repair medical materials, can solve the problems of changing the degradation rate of the stent, the single through-hole structure, and the low degree of control, achieve good cell compatibility, meet the requirements of bone repair, The effect of easy process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

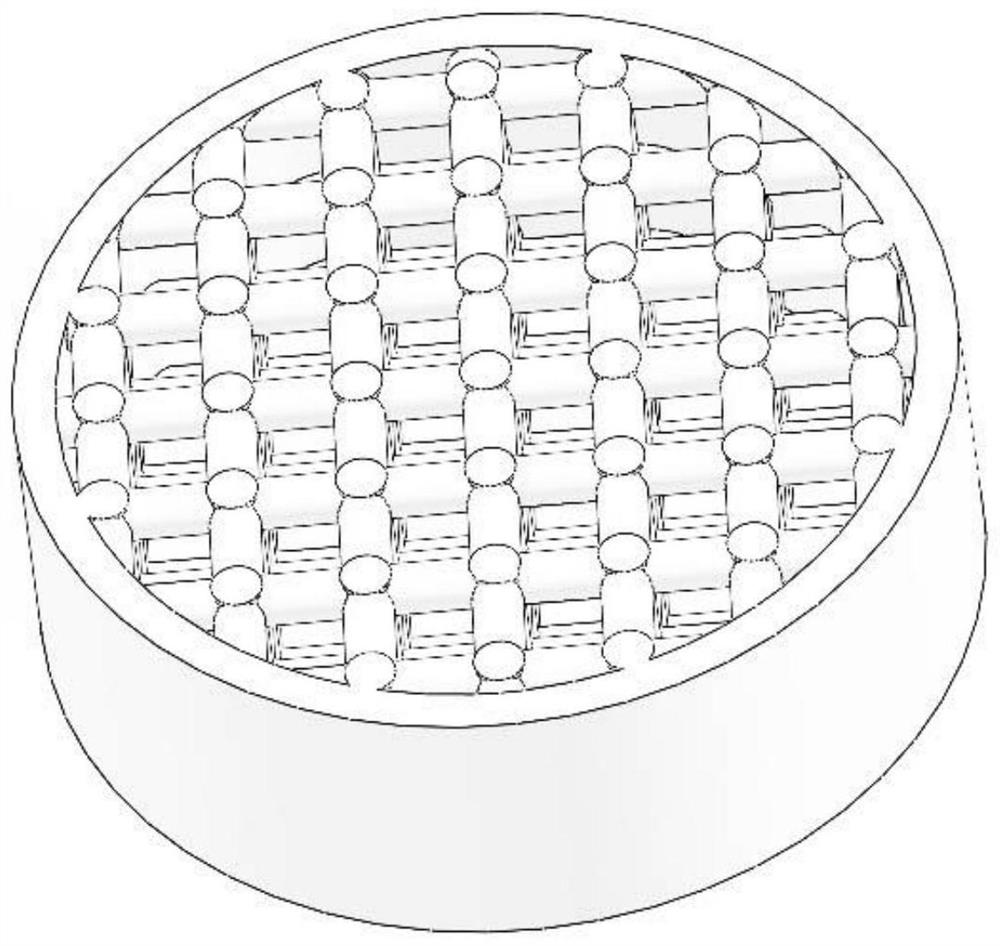

[0054] figure 1 It is a software modeling diagram of the calcium phosphate stent, and the shape of the calcium phosphate stent is matched and designed according to the defect site of the patient.

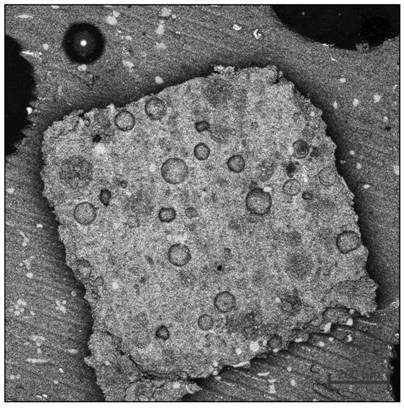

[0055] as attached figure 2 As shown, a controllable porous calcium phosphate scaffold, the composition of the calcium phosphate scaffold includes calcium phosphorus ceramics and calcium phosphate bone cement, the calcium phosphate scaffold is provided with a pore structure, the pore structure includes a macroporous structure, a microporous structure A pore structure and a through-hole structure, the calcium phosphate scaffold has a crystal structure, and a through-hole structure is arranged between the crystal structures.

[0056] Further, the calcium phosphorus ceramics include one or more combinations of hydroxyapatite and tricalcium phosphate.

[0057] Further, the calcium phosphate bone cement includes tetracalcium phosphate, octacalcium phosphate, calcium dihydrogen phospha...

Embodiment 2

[0072] This embodiment is carried out on the basis of the above-mentioned embodiment 1, and the similarities with the above-mentioned embodiment 1 will not be repeated.

[0073] This embodiment mainly introduces the regulation method of the pore structure of the scaffold.

[0074] The method for adjusting the aperture of the macroporous structure includes adjusting model precision and 3D printer precision; the source of the macroporous structure is that the sacrificial mold prepared by the printer is obtained after demoulding, so the size and shape of the macroporous structure depend on The size and shape of the printed sacrificial mold, and the minimum size of the sacrificial mold depend on the accuracy of the printer, so the size and shape of the macro-pore structure is prepared by building a model with software and demoulding after 3D printing.

[0075] The method for adjusting the pore diameter of the microporous structure includes adjusting the size and shape of the pore-...

Embodiment 3

[0080] This embodiment is carried out on the basis of the above-mentioned embodiment 1, and the similarities with the above-mentioned embodiment 1 will not be repeated.

[0081] This embodiment mainly introduces a preparation method of a scaffold with 60% porosity, 400 μm penetrating macropores, 60 μm spherical micropores, and appropriate amount of intercrystalline through holes.

[0082] Photosensitive resin is used as the sacrificial mold material for the bracket, 60 μm PMMA microspheres are used as the pore-forming agent, and the pouring slurry is a mixture of hydroxyapatite and α-tricalcium phosphate.

[0083] Implementation steps include:

[0084] S301. Prefabricate photosensitive resin sacrificial model with SLA 3D printer: first use solidworks software to construct a cylinder model with a diameter of 10mm and a height of 3mm, and build an interconnected cylinder structure in this model, with a diameter of 400μm, and form a 400μm after demoulding The through-macro holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com