A core for a roll of material

A core and coil technology, applied in the core field of coils, can solve problems such as cracking, machine damage, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Referring to Figure 1, there is shown a core 2 made of cardboard material. The core 2 is shown positioned between two mounting parts 4, 6 which are schematically shown and which may form suitable parts of a wide range of printing machines. The core 2 may be required to have a length of 700mm to over 4300mm. When the paper roll 8 is almost used up on the core 2, the core can be rotated at a speed of 1400-2900 rpm.

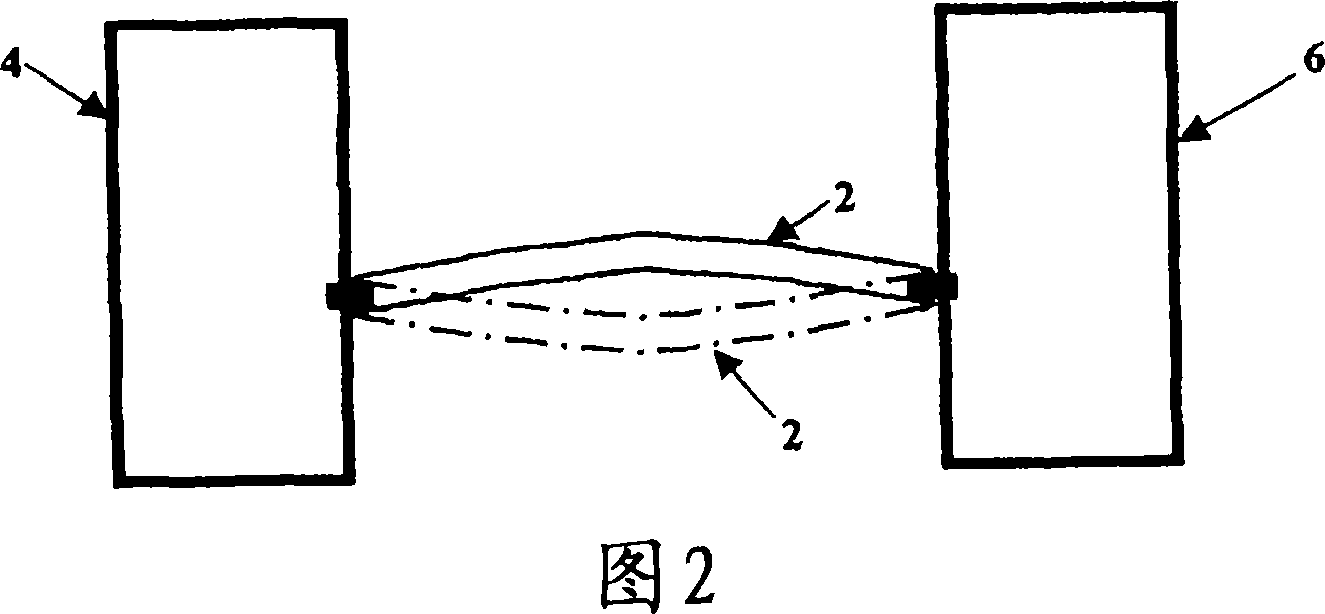

[0030] Figure 2 shows how the core 2 has a tendency to start spinning uncontrollably. As a result of the deformation of the core 2 into the shape shown in FIG. 2 , the core 2 is subjected to a high degree of vibration and rotates out of a straight line.

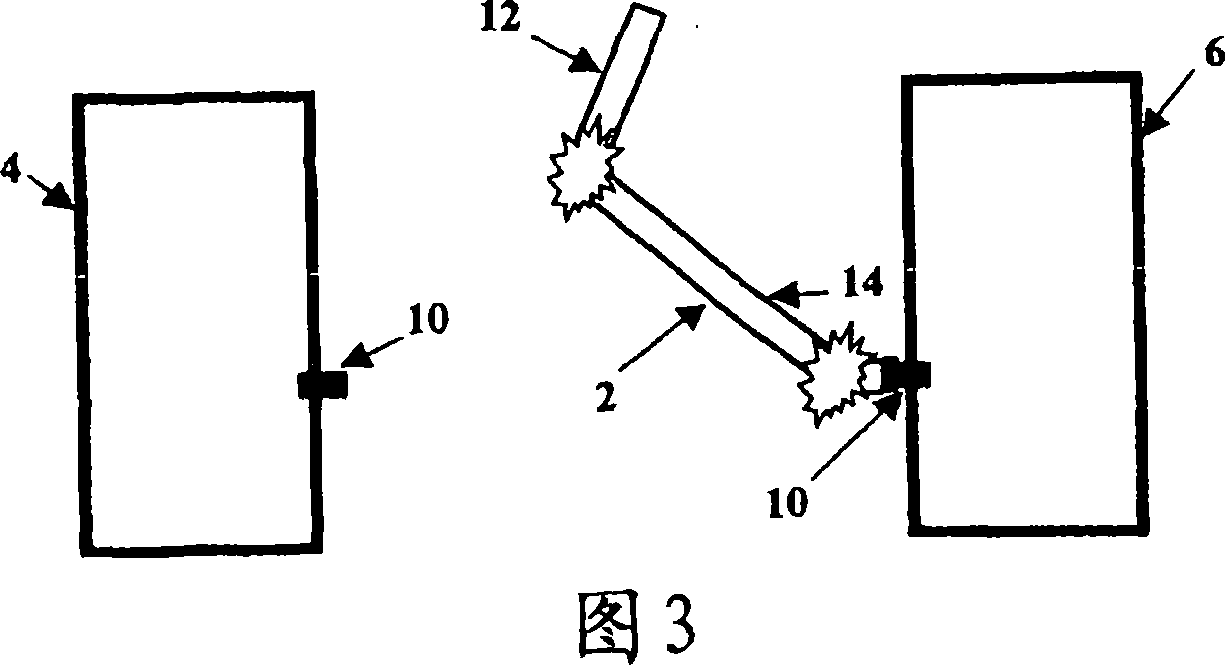

[0031] FIG. 3 shows what happens if the rotation of the core 2 continues when the core 2 is in the situation shown in FIG. 2 . More specifically, it can be seen from FIG. 3 that the core 2 has been broken into large sections loosened from the mounting part 10 . Large fractured sections 12 , 14 of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com