High-emissivity and high-entropy ceramic material and preparation method and application thereof

A high-emissivity, ceramic material technology, applied in the field of high-entropy ceramic materials, can solve the problems that limit the wide application of LaMgAl, and achieve the effects of favorable spectral emissivity, reduced band gap, and pure phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a method for preparing a high-emissivity high-entropy ceramic material described in the above technical solution, comprising the following steps:

[0031] Mix lanthanum source, neodymium source, gadolinium source, samarium source, rare earth oxide, magnesium source and aluminum source, and perform cold pressing to obtain a green body; the lanthanum source, neodymium source, gadolinium source, samarium source, rare earth oxide The molar ratio of lanthanum element, neodymium element, gadolinium element, samarium element, rare earth element, magnesium element and aluminum element in the magnesium source and aluminum source is (0.4-x):0.2:0.2:0.2:x:1:11; The rare earth oxides include Pr 6 o 11 , CeO 2 or Eu 2 o 3 ;

[0032] Insulating the green body in stages to obtain a high-emissivity high-entropy ceramic material;

[0033] The step-by-step heat preservation process includes: the first stage: the calcination temperature is 1300-1350°C,...

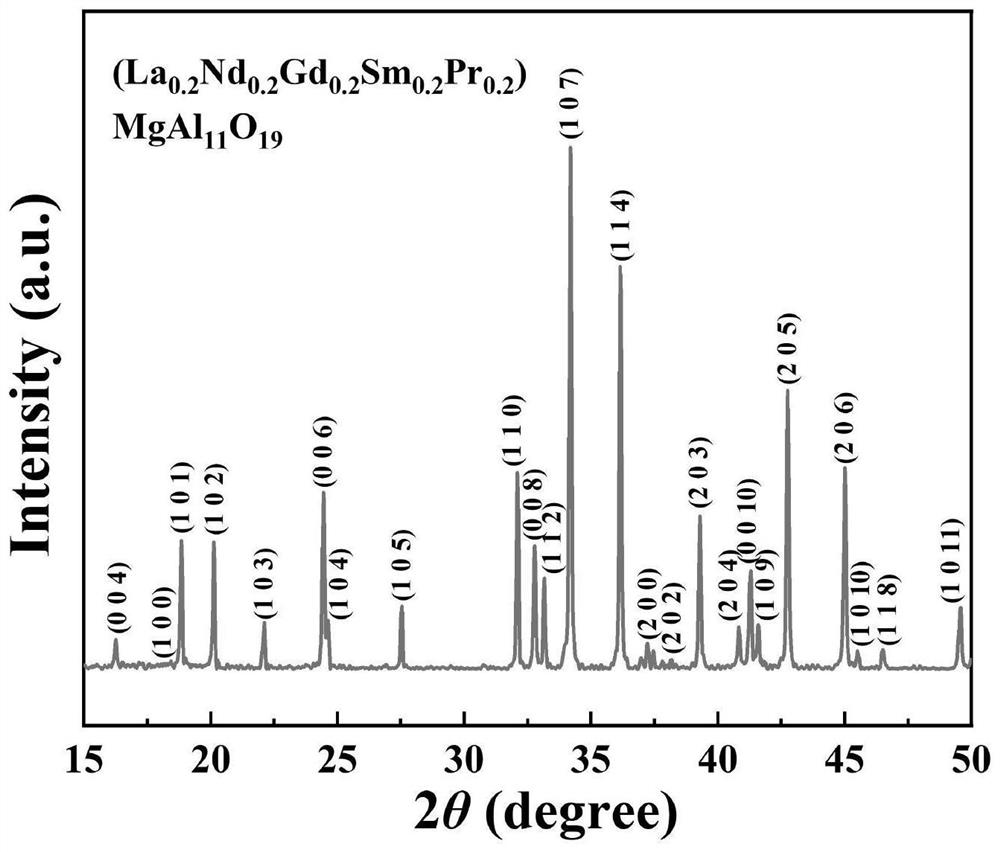

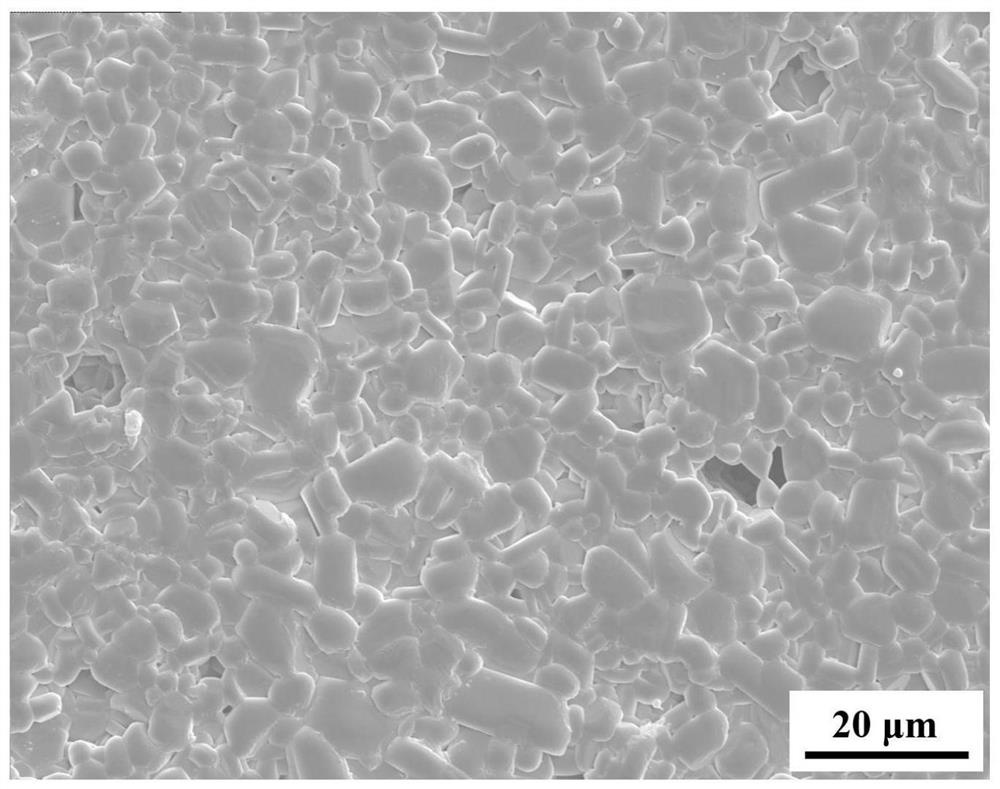

Embodiment 1

[0048] La 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Nd 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Gd 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Sm 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Pr 6 o 11 Powder (average particle size 50nm, purity ≥ 99.9%), Al 2 o 3 Powder (average particle size is 50nm, purity ≥ 99.9%) and MgO powder (average particle size is 50nm, purity ≥ 99.9%) according to (La 0.2 Nd 0.2 Gd 0.2 S m 0.2 PR 0.2 )MgAl 11 o 19 The stoichiometric ratio is batched, where La 2 o 3 Powder, Nd 2 o 3 Powder, Gd 2 o 3 Powder, Sm 2 o 3 Powder, Pr 6 o 11 powder, MgO powder and Al 2 o 3 The molar ratio of the powder is 0.2:0.2:0.2:0.2:0.067:2:11. Mix the obtained mixture with absolute ethanol and perform wet ball milling. The ball milling speed is 300rpm and the ball milling time is 6h to obtain light gray mixed powder body;

[0049] Put the light gray mixed powder into a stainless...

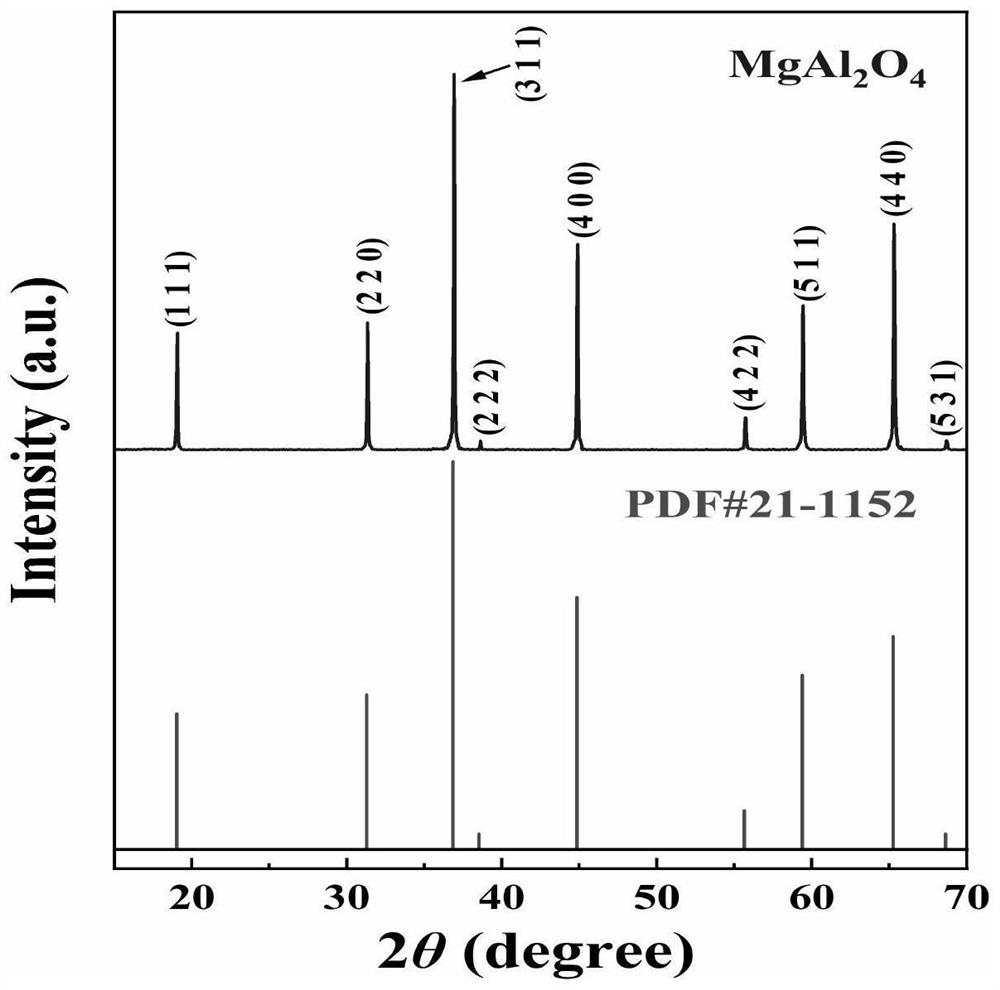

Embodiment 2

[0052] La 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Nd 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Gd 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), Sm 2 o 3 Powder (average particle size 50nm, purity ≥ 99.9%), CeO 2 Powder (average particle size 50nm, purity ≥ 99.9%), Al 2 o 3 Powder (average particle size is 50nm, purity ≥ 99.9%) and MgO powder (average particle size is 50nm, purity ≥ 99.9%) according to (La 0.2 Nd 0.2 Gd 0.2 S m 0.2 Ce 0.2 )MgAl 11 o 19 The stoichiometric ratio is batched, where La 2 o 3 Powder, Nd 2 o 3 Powder, Gd 2 o 3 Powder, Sm 2 o 3 Powder, CeO 2 Powder, Al 2 o 3 The molar ratio of the powder and the MgO powder is 0.2:0.2:0.2:0.2:0.4:11:2, the resulting mixture is mixed with absolute ethanol, and wet ball milled, the ball milling speed is 325rpm, and the ball milling time is 5h, to obtain Light blue mixed powder;

[0053] Put the light blue mixed powder into a stainless steel mold, ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com