Ultrasonic preparation method of protein peptide-polysaccharide nanoparticles loaded with bioactive components

A bioactive ingredient and nanoparticle technology, which is applied in the field of ultrasonic treatment technology to prepare composite nanoparticles, can solve the problems of large amount of ethanol added, increased preparation cost, unfavorable freeze-drying, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

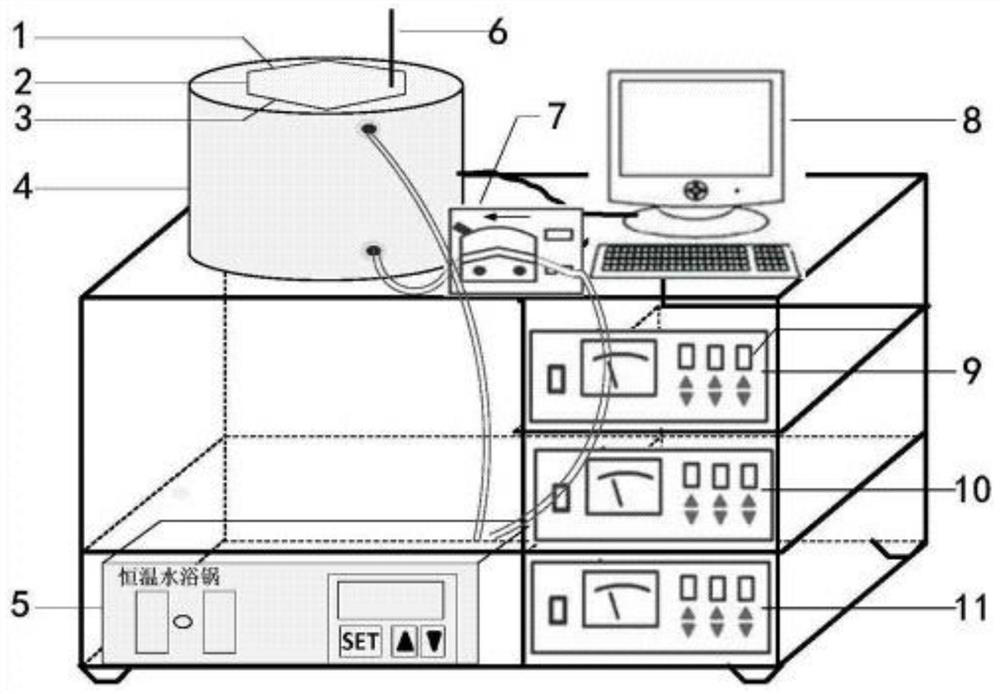

Method used

Image

Examples

Embodiment 1

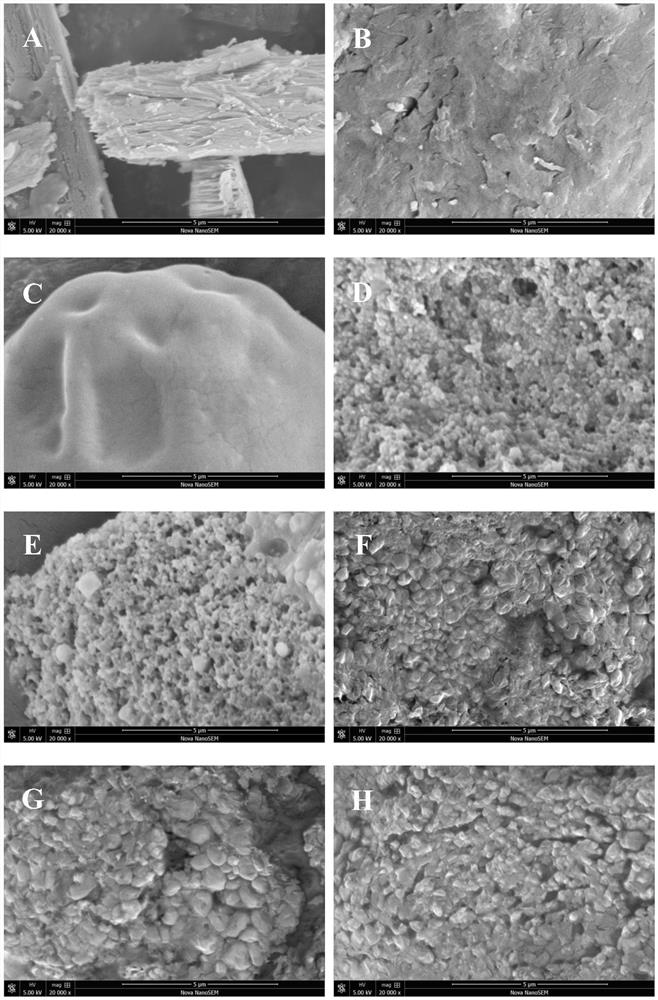

[0040] Example 1: Optimization of casein phosphopeptide concentration in the preparation of quercetin-loaded casein phosphopeptide-chitosan composite nanoparticles

[0041] (1) dissolving the casein phosphopeptide in distilled water so that the concentrations of the casein phosphopeptide are (1.0, 1.5, 2.0, 2.5, 3.0) mg / ml respectively, and adjusting the pH of the solution to 11;

[0042] (2) Chitosan is dissolved in 1% glacial acetic acid solution, and magnetically stirred until completely dissolved;

[0043] (3) dissolving quercetin in absolute ethanol to prepare quercetin stock solution;

[0044] (4) Stir the casein phosphopeptide solution in step (1) at a constant speed, and slowly add the quercetin stock solution in step (3) according to the mass ratio of quercetin to casein phosphopeptide is 1:15;

[0045] (5) Under the condition of stirring at room temperature, according to the mass ratio of casein phosphopeptide and chitosan as 1:1, an equal volume of step (2) chitosa...

Embodiment 2

[0050] Example 2: Optimization of the mass ratio of casein phosphopeptide to chitosan in the preparation of quercetin-loaded casein phosphopeptide-chitosan composite nanoparticles

[0051] (1) dissolving the casein phosphopeptide in distilled water so that the concentration of the casein phosphopeptide is 1.5 mg / ml, and adjusting the pH of the solution to be 11;

[0052] (2) Chitosan is dissolved in 1% glacial acetic acid solution, and magnetically stirred until completely dissolved;

[0053] (3) dissolving quercetin in absolute ethanol to prepare quercetin stock solution;

[0054] (4) Stir the casein phosphopeptide solution in step (1) at a constant speed, and slowly add the quercetin stock solution in step (3) according to the mass ratio of quercetin to casein phosphopeptide is 1:15;

[0055] (5) Under the condition of stirring at room temperature, according to the mass ratio of casein phosphopeptide and chitosan (1:0, 1:3, 1:2, 1:1, 2:1, 3:1), An equal volume of step (2) ...

Embodiment 3

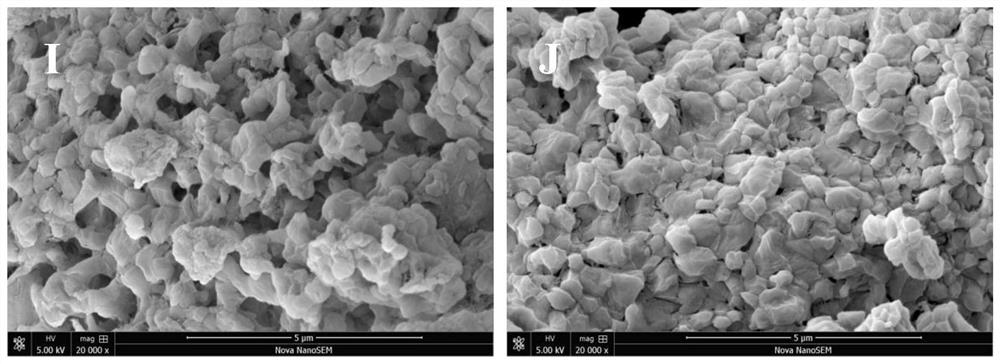

[0060] Example 3: Optimization of the mass ratio of quercetin to casein phosphopeptide in the preparation of quercetin-loaded casein phosphopeptide-chitosan composite nanoparticles

[0061] (1) dissolving the casein phosphopeptide in distilled water so that the concentration of the casein phosphopeptide is 1.5 mg / ml, and adjusting the pH of the solution to be 11;

[0062] (2) chitosan is dissolved in 1% glacial acetic acid solution, and magnetically stirred until completely dissolved;

[0063] (3) dissolving quercetin in absolute ethanol to prepare quercetin stock solution;

[0064] (4) The casein phosphopeptide solution in step (1) was stirred at a constant speed, according to the mass ratio of quercetin and casein phosphopeptide (1:5, 1:10, 1:12.5, 1:15, 1:20), slowly add step (3) quercetin stock solution;

[0065](5) Under the condition of stirring at room temperature, according to the mass ratio of casein phosphopeptide and chitosan as 1:1, an equal volume of step (2) ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com