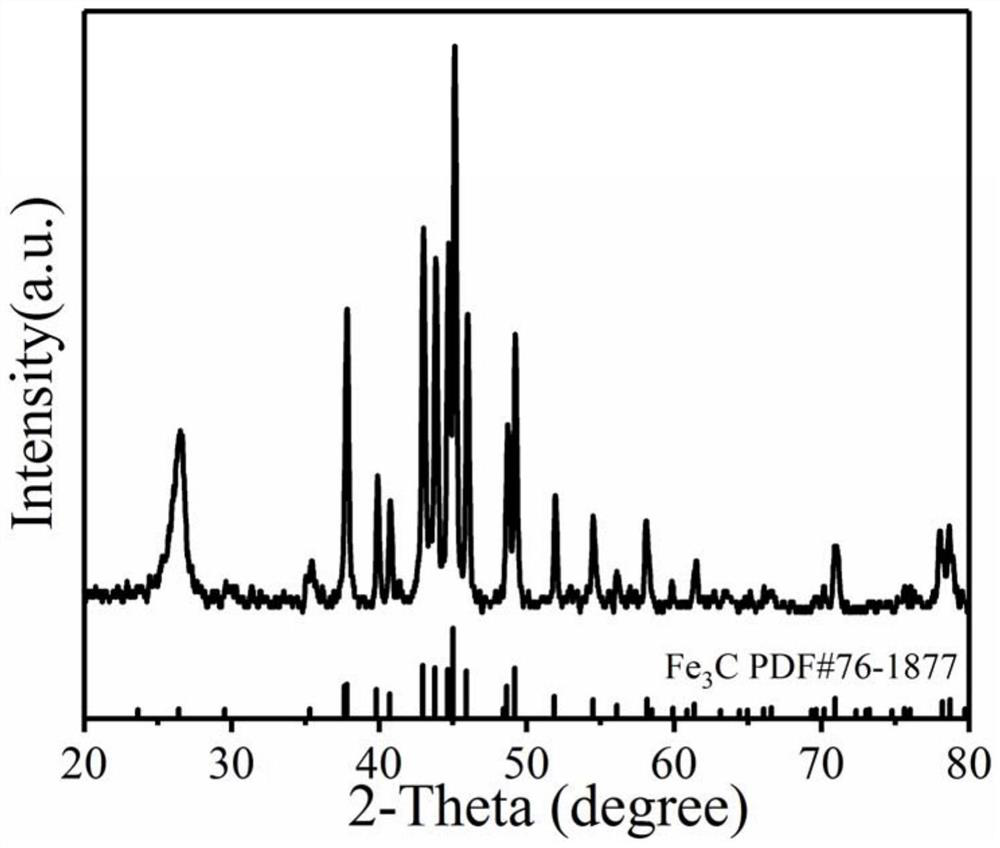

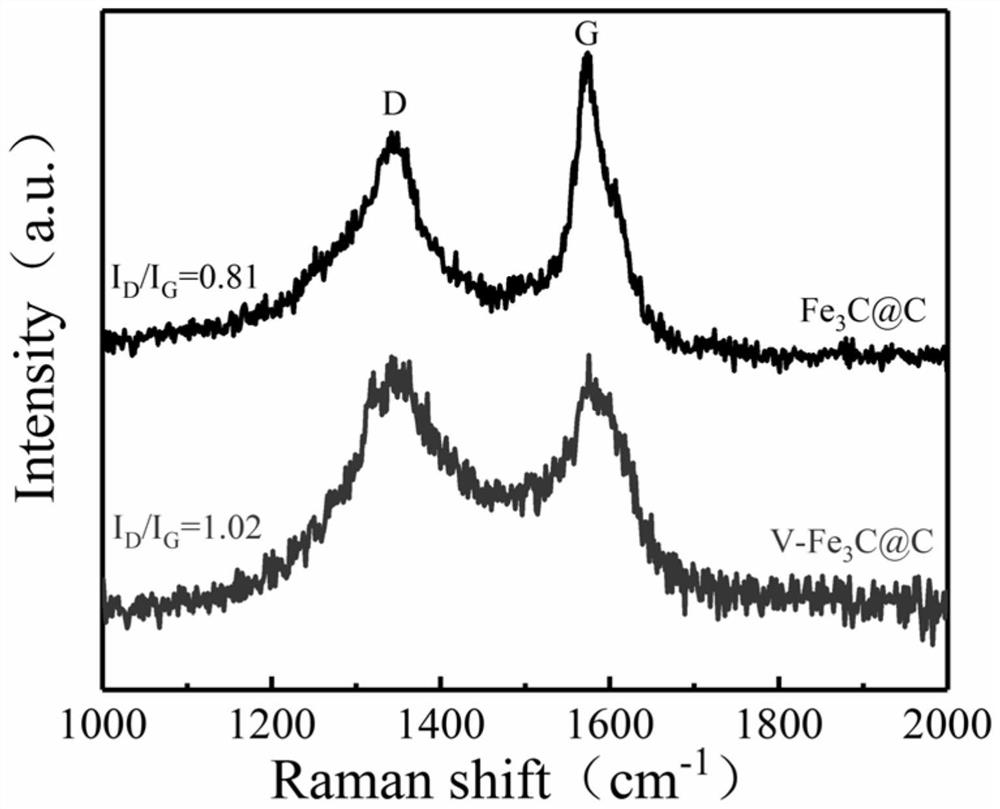

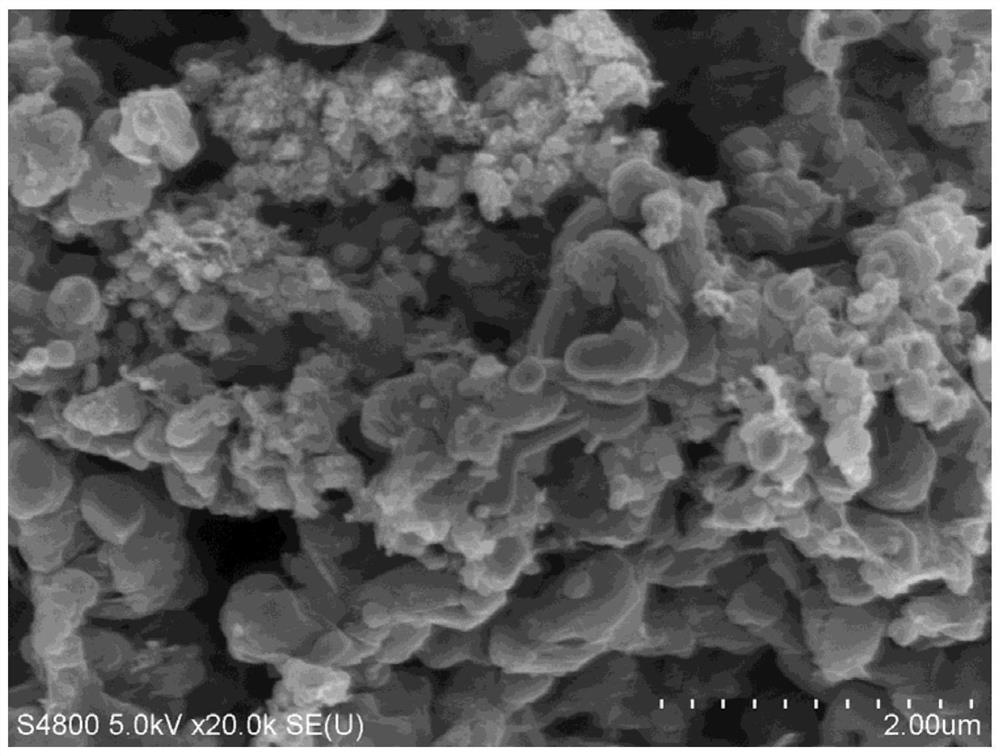

A kind of vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, preparation method and application thereof

An electrocatalyst and carbon coating technology, applied in the field of electrochemical catalysis, can solve the problems of limited application and limited electrocatalytic performance, and achieve the effects of high performance, optimized electronic conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention is a method for preparing a vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, comprising the following steps:

[0029] (1) Weigh sodium orthovanadate (Na 3 VO 4 ), ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dicyandiamide (C 2 H 4 N 4 ) and NaCl as a template (NaCl does not participate, protects, promotes V doping), and controls Na 3 VO 4 : FeCl 3 ·6H 2 O:C 2 H 4 N 4 : The mass ratio of NaCl is (0.01~0.06): (0.2~0.7): (2~4.5): (1~3.5), transfer the above substances to a beaker, add ethanol and stir well in a magnetic stirrer for 20~45 min , and then dried in a vacuum dryer at 60~80°C for 12~16 h to obtain the mixed raw materials. By mixing fully in this way, the reaction is uniform and the reaction is sufficient;

[0030] (2) Put the material obtained in step (1) into the porcelain boat, and place it in the heating position of the tube furnace, then vacuumize the tube furnace and pass argon as a pro...

Embodiment 1

[0034] The present invention is a method for preparing a vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, comprising the following steps:

[0035] (1) Weigh sodium orthovanadate (Na 3 VO 4 ), ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dicyandiamide (C 2 H 4 N 4 ) and sodium chloride (NaCl), and control Na 3 VO 4 : FeCl 3 ·6H 2 O:C 2 H 4 N 4 : The mass ratio of NaCl is 0.06:0.7:4.5:1, transfer the above substances to a beaker, add ethanol, stir well in a magnetic stirrer for 45 min, and then put them in a vacuum dryer for 60o C was dried for 12 h to obtain mixed raw materials;

[0036] (2) Put the material obtained in step (1) into the porcelain boat, and place it in the heating position of the tube furnace, then evacuating the tube furnace and feeding it with argon as a protective atmosphere, and the gas flow rate is 40 sccm / min .

[0037] (3) Set the heating rate of the tube furnace to 4 o C / min and raise the temperature t...

Embodiment 2

[0040] The present invention is a method for preparing a vanadium-doped carbon-coated iron carbide multifunctional composite electrocatalyst, comprising the following steps:

[0041] (1) Weigh sodium orthovanadate (Na 3 VO 4 ), ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dicyandiamide (C 2 H 4 N 4 ) and sodium chloride (NaCl), and control Na 3 VO 4 : FeCl 3 ·6H 2 O:C 2 H 4 N 4 : The mass ratio of NaCl is 0.05:0.6:4:1.5, transfer the above substances to a beaker, add ethanol, stir well in a magnetic stirrer for 40 min, and then put them in a vacuum dryer for 60 minutes. o C was dried for 12 h to obtain mixed raw materials;

[0042] (2) Put the material obtained in step (1) into the porcelain boat, and place it in the heating position of the tube furnace, then evacuate the tube furnace and pass argon gas as a protective atmosphere, and the gas flow rate is 50 sccm / min .

[0043] (3) Set the heating rate of the tube furnace to 6 o C / min, and raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com