Methods to reduce molybdenum content after chamber maintenance

A chamber and content technology, used in discharge tubes, climate sustainability, final product manufacturing, etc., can solve problems such as less than ideal, and achieve the effect of reducing cleaning times, improving manufacturing yield, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

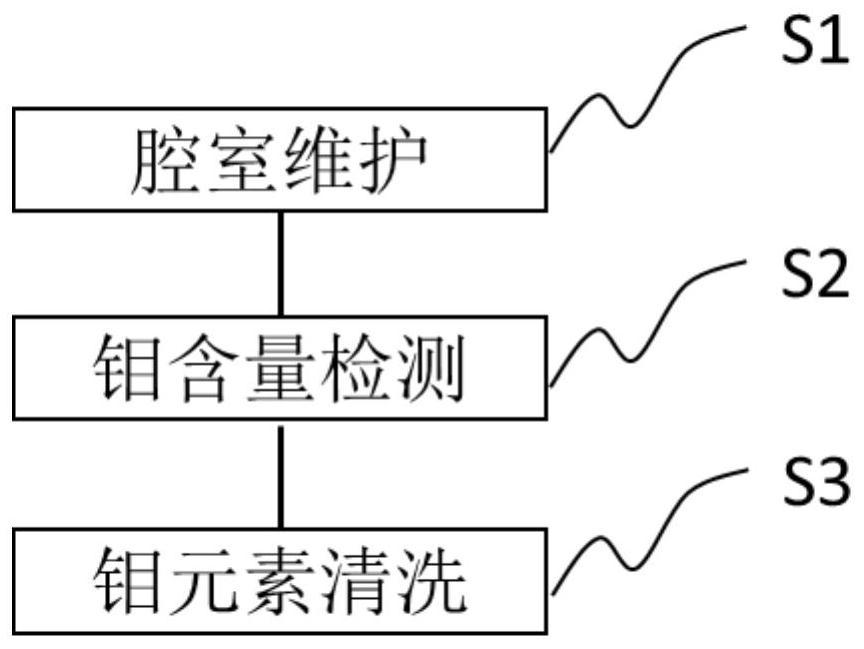

[0024] The method for reducing the molybdenum content after the maintenance of the chamber of Example 1 comprises the following steps:

[0025] S1, chamber maintenance;

[0026] Chamber maintenance mainly includes replacement of components and cleaning of the chamber.

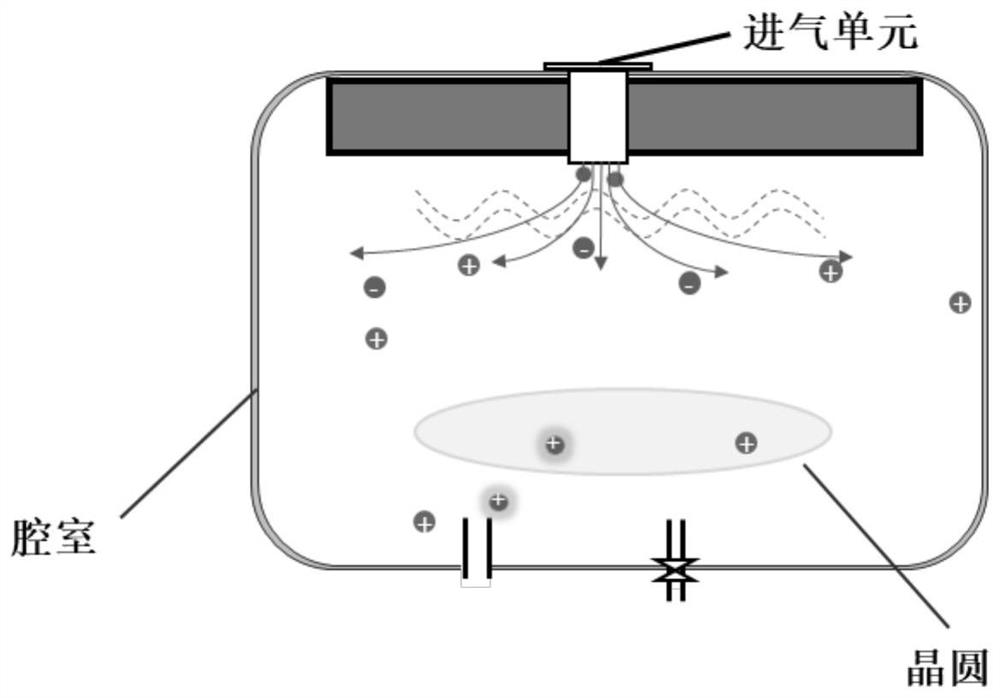

[0027] like figure 2 As shown, chamber cleaning typically utilizes a method of injecting a process gas, such as injecting a first process gas. The first process gas is injected through an air inlet unit, and the air inlet unit is located in the middle position of the top of the cavity. The flow rate of the first process gas can be controlled between 100 sccm and 1000 sccm. The first process gas is ionized to form a plasma before being passed through. The first process gas may be a gas that meets preset process requirements, such as a gas containing elements such as oxygen and fluorine, which is not limited here. At the same time, the reacted gas is discharged through the exhaust unit. This cleaning proce...

Embodiment 2

[0037] Embodiment 2 The method for reducing molybdenum content after chamber maintenance comprises the following steps:

[0038] S1, chamber maintenance;

[0039] Same as Example 1.

[0040] S2, chamber molybdenum content detection;

[0041] Same as Example 1.

[0042] S3, molybdenum element cleaning;

[0043] The number of PE-TEOS wafers placed in this step is obtained by calculation. Other methods are the same as in Example 1.

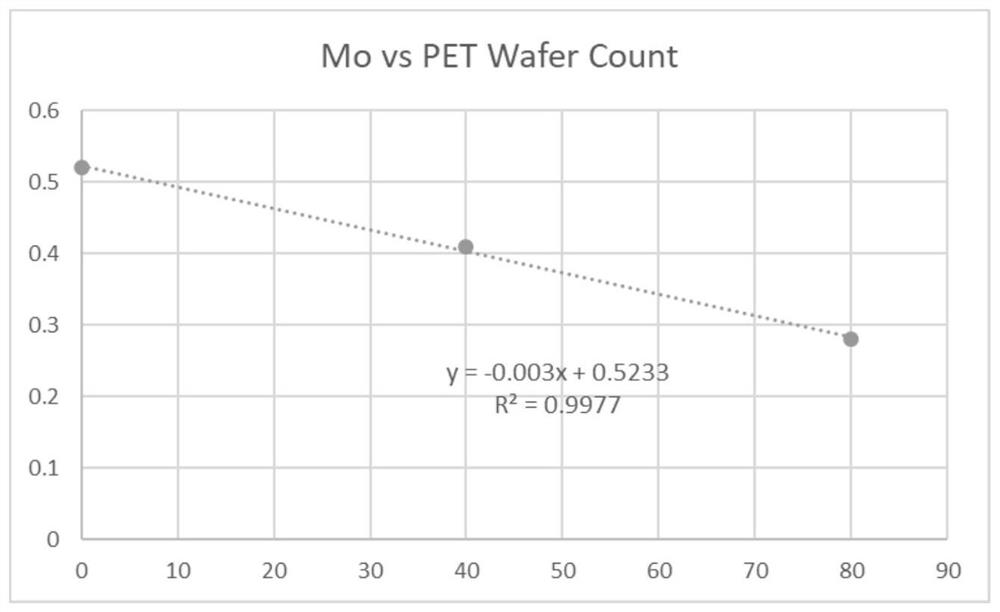

[0044] The calculation of the number of PE-TEOS wafers placed can be obtained according to the curve fitted by the experiment, such as image 3 . When the upper limit of the concentration requirement of molybdenum element is determined, the number of PE-TEOS wafers can be determined. For example, the upper limit of concentration is set to 0.4, the number of PE-TEOS wafers is 40pcs, the upper limit of concentration is set to 0.3, and the number of PE-TEOS wafers is 80pcs.

[0045] By using the above method, different numbers of PE-TEOS wafers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com