Residual stress standard test block valuing and tracing method

A residual stress and standard test block technology, applied in the direction of force/torque/power measuring instrument calibration/testing, measuring devices, instruments, etc., can solve the problem that there is no relatively perfect method for the calibration of residual stress testing equipment, and achieve reliable traceability , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

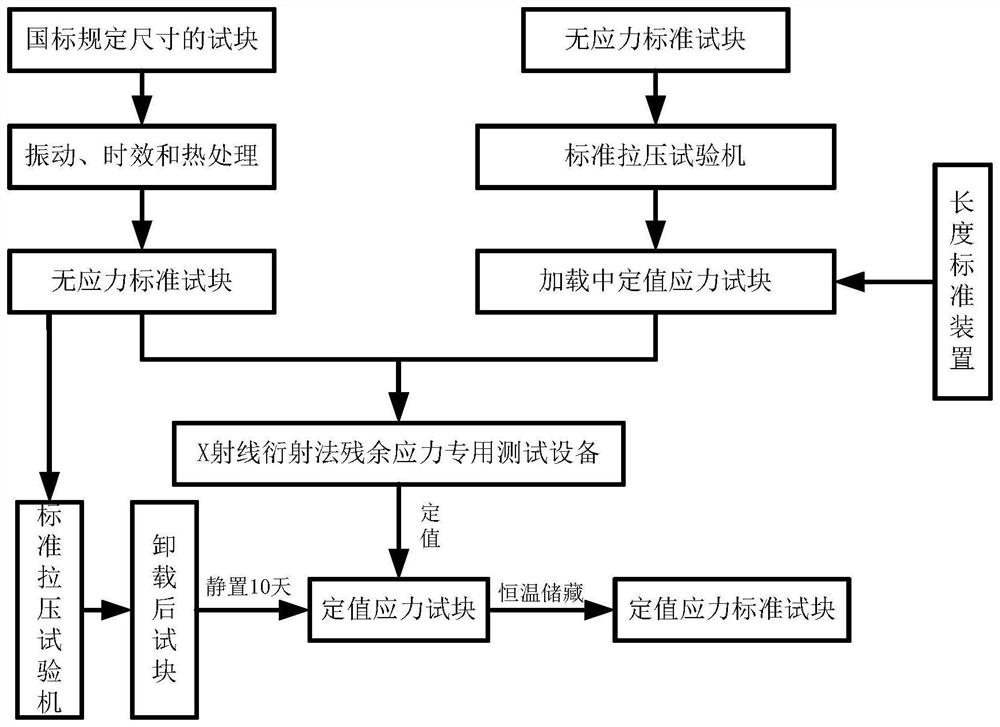

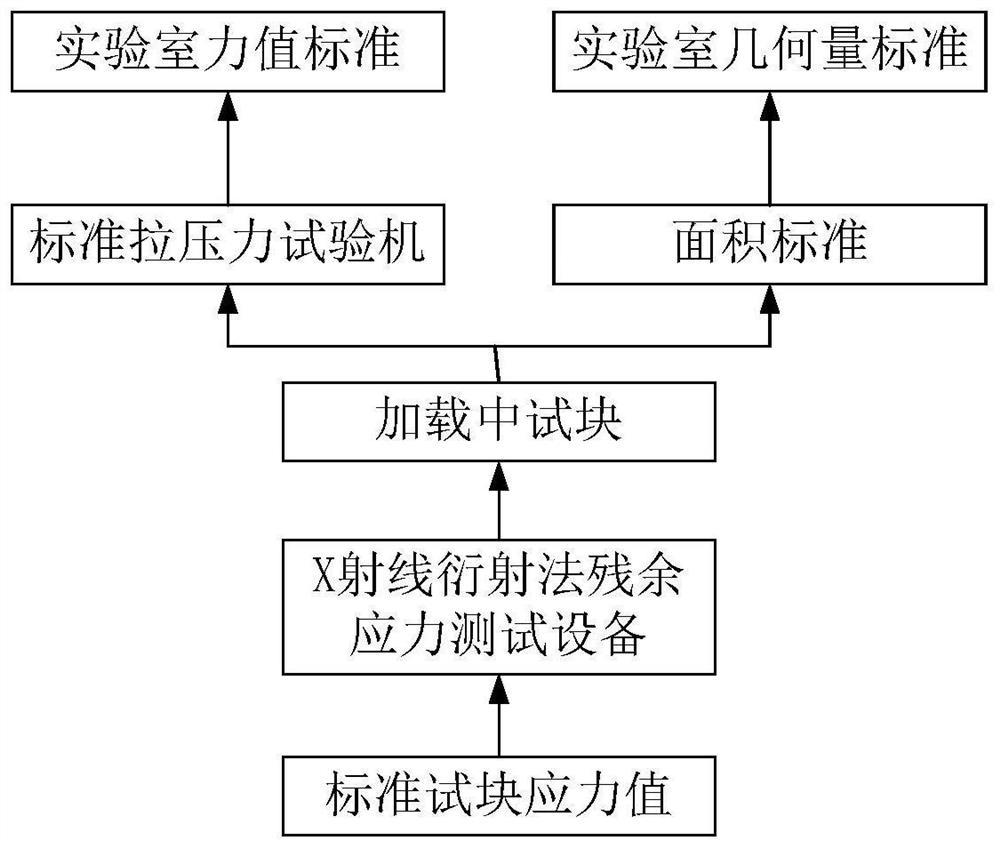

[0018] This embodiment discloses a residual stress standard test block determination and traceability method, the determination process is as follows figure 1 As shown, the standard fixed value stress test block can be traced back to the laboratory force value standard and length standard, using the calibrated X-ray diffraction residual stress test equipment as the transfer standard to determine the value of the test block, and the fixed value stress standard Test block, used for calibration of residual stress testing equipment.

[0019] This embodiment discloses a method for determining the value of a residual stress standard test block as follows: firstly, using a combination of vibration, aging and heat treatment to eliminate stress on a test block with a specified size and structure in the national standard to obtain a stress-free standard test block. Utilize the standard tension-compression testing machine to load the stress-free standard test block, which becomes the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com