A printing plate decontamination and scratch removal double-effect cleaning liquid and preparation method thereof

A plate cleaning solution and scratch technology, applied in the direction of chemical instruments and methods, gel preparation, silicon compounds, etc., can solve the problems of poor antibacterial performance, inability to protect and repair the plate, and affect the mission of use, so as to ensure cleanliness and reduce The chance of small scratches or scratches, the effect of good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

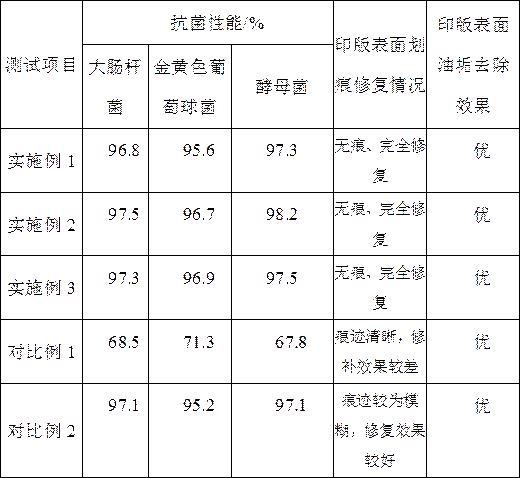

Examples

Embodiment 1

[0030] A printing plate decontamination and scratch double-effect cleaning liquid, prepared from the following components by weight: 1.0 parts of gum arabic, 0.5 parts of polyvinyl alcohol, 0.8 parts of hydroxyethyl cellulose, and 0.53 parts of nanopotassium Feldspar powder, 0.7 part sodium dodecylbenzene sulfonate, 0.3 part castor oil, 0.2 part squalane, 0.7 part repair aid, 0.4 part dimethyl sulfate, 0.32 part dextrin, 0.3 part citric acid, 1.0 part Phosphoric acid, 0.4 parts of triethanolamine, 0.4 parts of D-mannitol and 40 parts of deionized water.

[0031] The preparation method of repair auxiliary agent comprises the following steps:

[0032] Ⅰ. Accurately weigh the appropriate amount of tetraethyl silicate, dimethyldimethoxysilane and absolute ethanol according to the ratio of the amount of substances to 1:0.25:6. Transfer to an ice-water bath, and then add an appropriate amount of acid solution to the mixed solution while stirring, so that the acid solution and the m...

Embodiment 2

[0045] The printing plate decontamination and scratch removal double-effect plate cleaning solution provided in this embodiment and the preparation method are roughly the same as in Example 1, the main difference is that the proportioning of each raw material is different, specifically:

[0046] 1.2 parts of gum arabic, 0.6 parts of polyvinyl alcohol, 1.0 parts of hydroxyethyl cellulose, 0.6 parts of nano potassium feldspar powder, 0.9 parts of sodium dodecylbenzenesulfonate, 0.38 parts of castor oil, 0.3 parts of squalane, 1.0 parts Repair aid, 0.45 parts of dimethyl sulfate, 0.35 parts of dextrin, 0.32 parts of citric acid, 1.2 parts of phosphoric acid, 0.45 parts of triethanolamine, 0.5 parts of D-mannitol and 45 parts of deionized water.

Embodiment 3

[0048] The printing plate decontamination and scratch removal double-effect cleaning solution provided in this embodiment and the preparation method are roughly the same as in Example 1, the main difference is that the proportioning of each raw material is different, specifically:

[0049] 1.5 parts of gum arabic, 0.8 parts of polyvinyl alcohol, 1.3 parts of hydroxyethyl cellulose, 0.65 parts of nano potassium feldspar powder, 1.2 parts of sodium dodecylbenzenesulfonate, 0.45 parts of castor oil, 0.4 parts of squalane, 1.2 parts Repair aid, 0.5 part of dimethyl sulfate, 0.38 part of dextrin, 0.35 part of citric acid, 1.5 part of phosphoric acid, 0.5 part of triethanolamine, 0.7 part of D-mannitol and 50 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com