Carbon nanotube epoxy resin composite material electrode and preparation method and application thereof

A carbon nanotube and epoxy resin technology, which is applied in the field of tobacco chemistry, can solve the problems affecting the stability and service life of electrodes, the carbon nanotube modified layer is easy to fall off, the carbon nanotube modified layer is peeled off, etc., and achieves significant electrocatalytic activity. , the effect of low cost of raw materials and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of carbon nanotube epoxy resin composite electrode

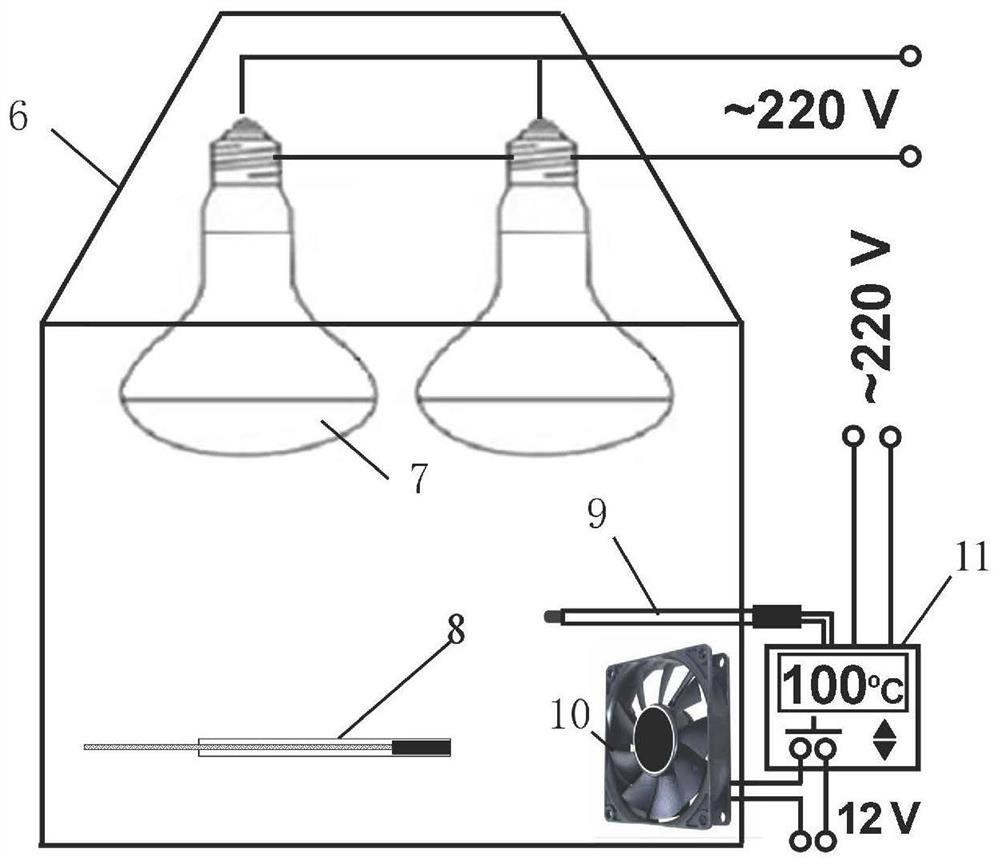

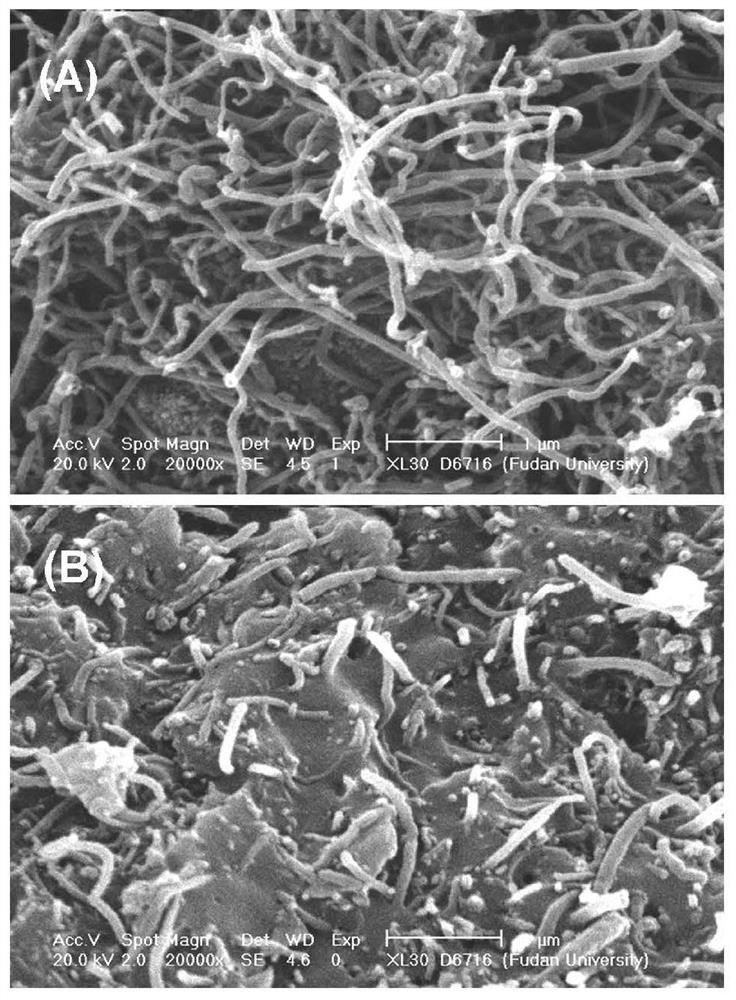

[0044] Disperse 2 grams of commercial carbon nanotubes with a purity higher than 95% in a flask filled with 500 ml of concentrated nitric acid, heat treatment in a water bath at 60°C for 12 hours, and mechanically stir the mixture in the bottle at a speed of 120 rpm minute. After the nitric acid oxidation heat treatment mixture is cooled to room temperature, filter it under reduced pressure, and wash it with a large amount of water by means of a water pump, and continuously check with pH test paper until the pH value of the filtrate is higher than 5. Then, place the solid in the figure 2 In a metal box with air holes, dry at 110°C for 20 minutes to obtain nitric acid oxidation-treated carbon nanotubes.

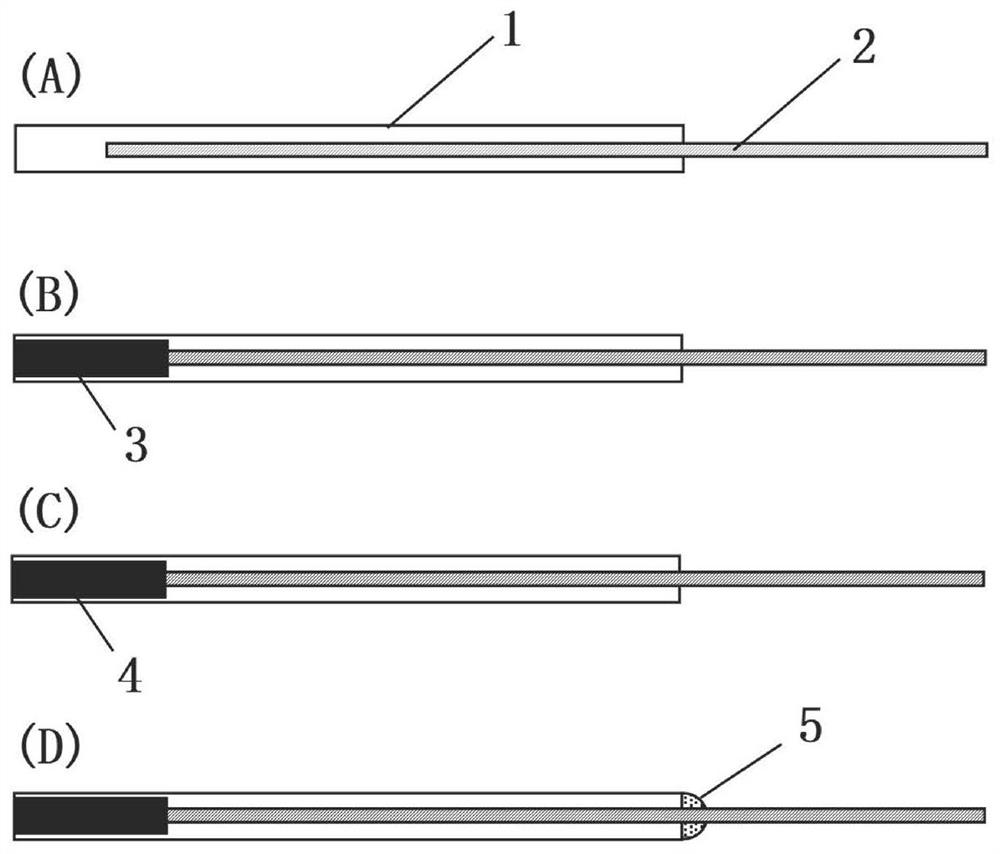

[0045] The preparation process of the carbon nanotube epoxy resin composite electrode is shown in the appendix figure 1 . Mix the E51 type epoxy resin prepolymer and the supporting epoxy...

Embodiment 2

[0055]Example 2: A carbon nanotube epoxy resin composite electrode for voltammetric analysis of tobacco chemical components and its preparation method

[0056] Different from the electrode in Example 1, the area of the working electrode used in various voltammetry analysis methods such as linear voltammetry analysis, cyclic voltammetry analysis, stripping voltammetry analysis, and differential pulse voltammetry analysis of tobacco chemical components is larger. The diameter of the circular electrode used is 1 to 6 millimeters, that is, the inner diameter of the electrode tube is required to be relatively large; at the same time, a carbon nanotube epoxy resin composite material mixture with a higher viscosity and a higher content of carbon nanotubes is used.

[0057] The preparation steps are the same as in Example 1. The difference is: weigh 1 gram of treated carbon nanotube powder and mix it with 1 gram of epoxy resin prepolymer containing curing agent, and stir thoroughly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com