Polyimide film and preparation method thereof

A polyimide film and a polymerization reaction technology, applied in the field of polyimide film and its preparation, can solve the problems of poor stability, increased cost, uneven mixing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

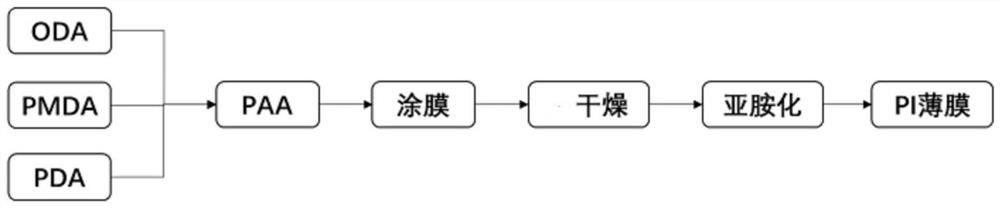

[0022] The invention provides a kind of preparation method of polyimide film, comprises the following steps:

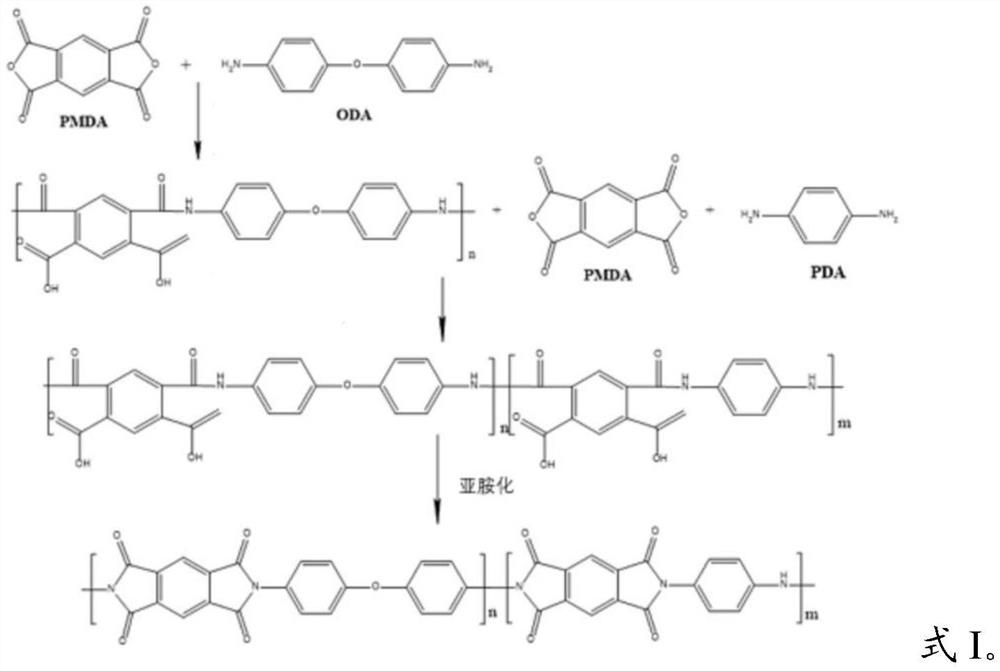

[0023] (1) mixing 4,4'-diaminodiphenyl ether, an organic solvent and pyromellitic anhydride to perform a first polymerization reaction to obtain a first precursor solution;

[0024] (2) mixing the first precursor solution obtained in the step (1) with p-phenylenediamine, an organic solvent and pyromellitic anhydride, and performing a second polymerization reaction to obtain a second precursor solution;

[0025] (3) First coating the second precursor solution obtained in the step (2) on the substrate, and then performing imidization treatment to obtain a polyimide film.

[0026] The present invention mixes 4,4'-diaminodiphenyl ether, an organic solvent and pyromellitic anhydride to perform a first polymerization reaction to obtain a first precursor solution. In the invention, 4,4'-diaminodiphenyl ether (ODA), an organic solvent and pyromellitic anhydride (PMDA) are fi...

Embodiment 1

[0053] Step 1: Add ODA (12.0g, 0.06mol) into a 500mL reactor, add DMAc (186.1g), turn on mechanical stirring and control the temperature at 35°C to dissolve ODA; after ODA is completely dissolved, control the temperature of the solution to drop to 25°C, add PMDA (12.64g, 0.058mol), under the protection of nitrogen, carry out the first polymerization reaction 0.5h, obtain the first precursor solution;

[0054] Step 2: Dissolve PDA (15.12g, 0.14mol) in DMAc (186.1g), then add to the first precursor solution and mix, add PMDA (28.78g, 0.132mol) after mixing completely, react for 0.5h, and then Add PMDA (1.31g, 0.006mol) to react for 0.5h, add PMDA (0.872g, 0.004mol) again to react for 0.5h, and the time of the second polymerization reaction is 1.5h in total to obtain the second precursor solution;

[0055] Step 3: Use an automatic coating machine to coat the second precursor solution on the glass plate with a wet film thickness of 150 μm, put it on a constant temperature heating ...

Embodiment 2

[0057] Step 1: Add ODA (16.0g, 0.08mol) into a 500mL reactor, add DMAc (201.9g), turn on mechanical stirring and control the temperature at 35°C to dissolve ODA; after ODA is completely dissolved, control the temperature of the solution to drop to 25°C, add PMDA (17.0g, 0.078mol), carry out the first polymerization reaction 0.5h under nitrogen protection, obtain the first precursor solution;

[0058] Step 2: Dissolve PDA (12.96g, 0.12mol) in DMAc (201.9g), then add to the first precursor solution and mix, add PMDA (28.78g, 0.132mol) after mixing completely, react for 0.5h, and then Add PMDA (1.31g, 0.006mol) to react for 0.5h, add PMDA (0.872g, 0.004mol) again to react for 0.5h, and the time of the second polymerization reaction is 1.5h in total to obtain the second precursor solution;

[0059] Step 3: Use an automatic coating machine to coat the second precursor solution on the glass plate with a wet film thickness of 150 μm, put it on a constant temperature heating table at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com