A piezoelectric control system and method for printing and preparing high-uniform device film layers

A technology for controlling the system and film layer, applied in the direction of the spray device, etc., can solve the problems of uneven film formation, uneven film layer, insufficient spray volume, etc., to improve the film formation uniformity, improve the detection efficiency, and improve the film quality. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

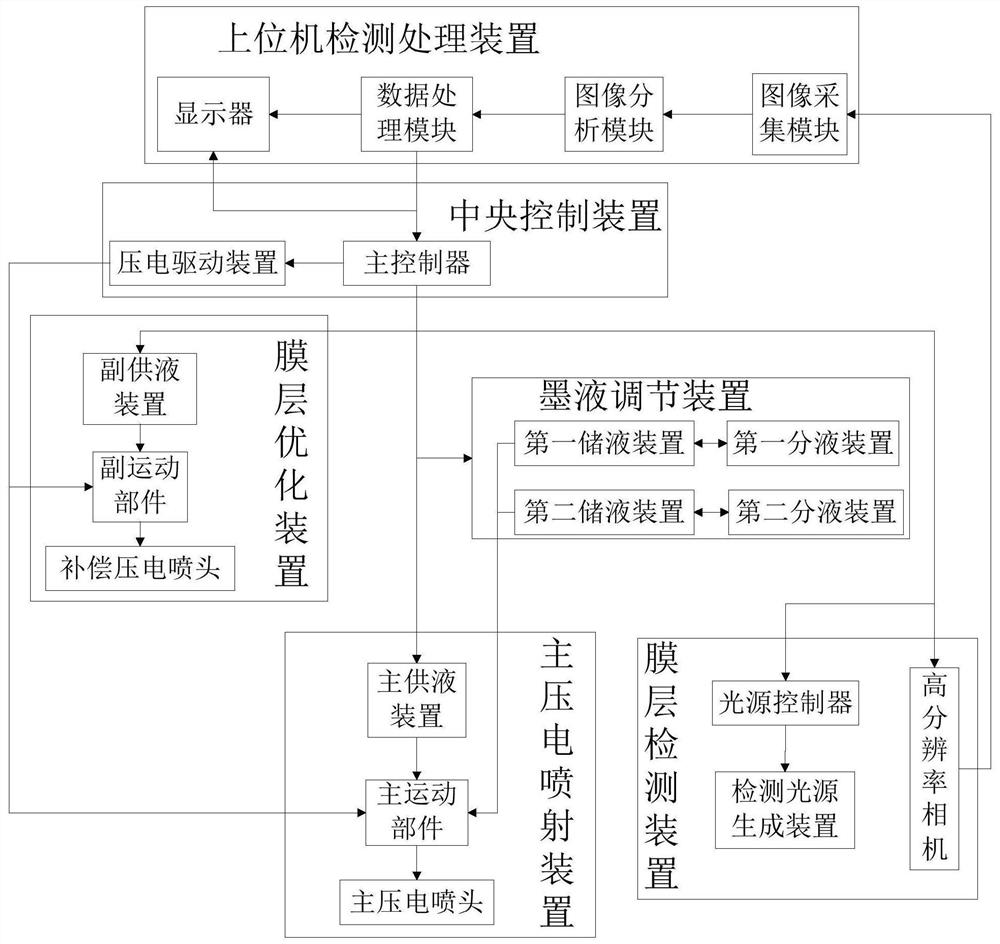

[0055] Such as figure 1 with figure 2 As shown, this embodiment provides a piezoelectric control system for printing and preparing high-uniform device film layers. The system includes: a central control device, a main piezoelectric injection device, an ink adjustment device, a film layer detection device, and a film layer optimization The device and the upper computer detection and processing device, the main piezoelectric injection device, the ink adjustment device, the film layer detection device, the film layer optimization device and the upper computer detection and processing device are respectively connected with the central control device, and the upper computer detection and processing device is connected with the film layer detection device. device connection.

[0056] combine figure 1 with figure 2 As shown, the central control device is equipped with a main controller and a piezoelectric drive device, and the main controller is connected with the piezoelectric ...

Embodiment 2

[0067] Such as Figure 4As shown, this embodiment provides a piezoelectric control method for printing and preparing a highly uniform device film layer, the method includes the following steps:

[0068] Installation steps: Connect the main piezoelectric injection device, ink adjustment device, film layer detection device, film layer optimization device, and host computer detection and processing device with the central control device, and set the film layer detection device in the host computer detection and processing device. Connected image acquisition module, the image acquisition module is used to obtain the original image of film formation detection;

[0069] Ink pretreatment step: deliver the raw liquid, the first solvent, and the second solvent to the main piezoelectric nozzle. In actual application, the main piezoelectric spraying device, the first liquid dispensing device, and the second liquid dispensing device respectively deliver the stock solution, the first solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com