Probiotic microcapsule and preparation method thereof

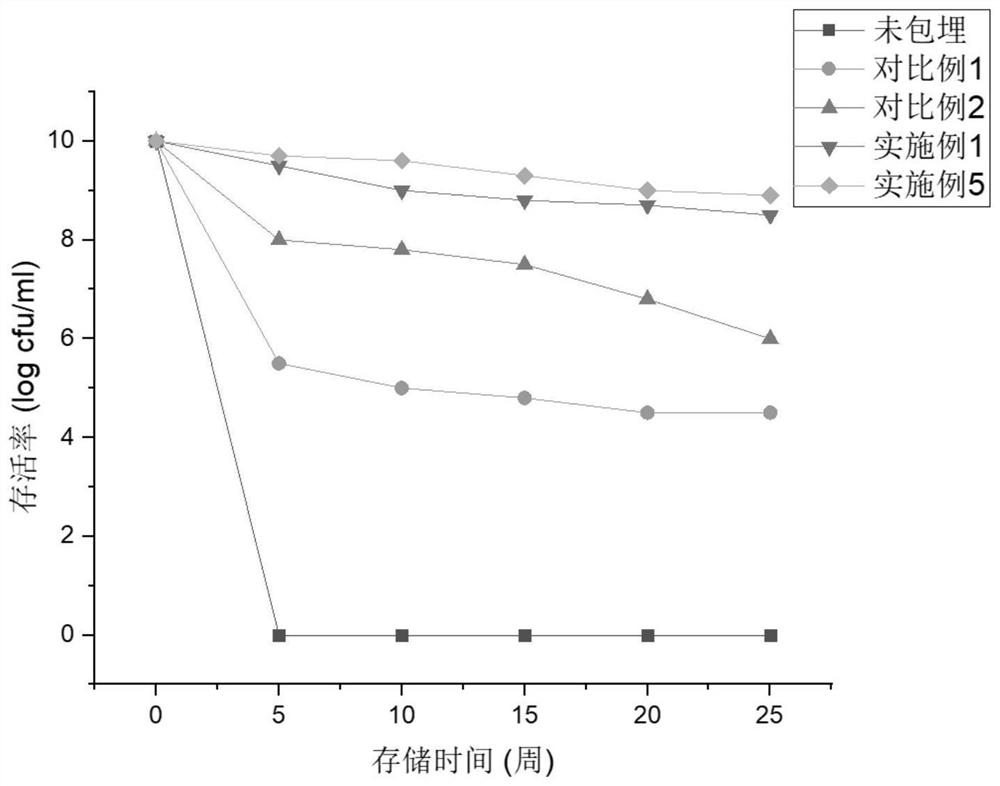

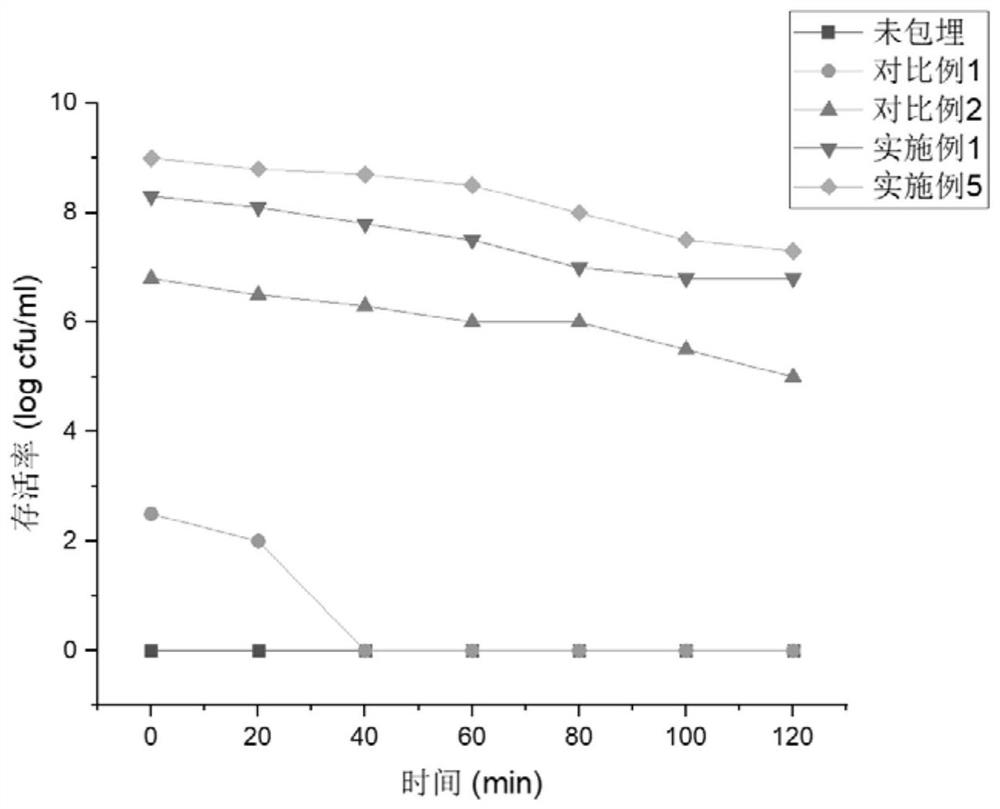

A probiotic and microcapsule technology, applied in microcapsule preparation, microsphere preparation, bacteria and other directions, can solve the problems of poor survival rate of probiotics, and achieve the effect of improving efficiency, improving survival rate and prolonging digestion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] An embodiment of the present invention proposes a method of preparing a probiotic microcapsule, comprising the steps of:

[0041] 1) Add phosphate buffer to porous starch, stand, add polyethylene imine, constant temperature oscillation, washing, drying, porous starch-polyethyleneimine carrier;

[0042] 2) Mix the above porous starch-polyethylene mine support and solid grease, a solution of an emulsifier, 40 ° C ~ 50 ° C constant temperature emulsification, cooling, porous starch-polyethyleneimine carrier of the solid grease;

[0043] 3) In the solution of the porous starch-polyethyleneimine carrier of the above-mentioned solid oil, triethylamine, dimethyl sulfoxide, stirring, and acetic anhydride, reaction, then dialyzed, freeze and dry, gave acetylated Porous starch-polyethyleneimine vector;

[0044] 4) In the above acetylated porous starch-polyethylene imine, the solution of the emulsifier is added, 40 ° C ~ 50 ° C emulsified, adding a lipase, 40 to 50 ° C for 10 to 20 mi...

Embodiment 1

[0091] Example 1 Preparation method of probiotics microcapsules, including the following steps:

[0092] (1) Preparation of porous starch: 2 g of strain is added to 250 mL of triangular bottle, adding 0.2 mol / L of sodium hydrogen phosphate and 0.1 mol / L citric acid buffer, 40mL, add 0.1 ml of toluene, add 0.1 ml of toluene to add appropriate dilution The enzyme solution, 40 ° C, constant temperature oscillated 24 h, centrifugal separation supernatant, precipitate at 60 ° C for normal pressure drying, and pulverized.

[0093] (2) Porous starch-polyethyleneimine carrier preparation: accurately weigh 2.0 g of corn porous starch, placed in a beaker, to balance the vector, add 200 ml of phosphate buffer (pH 8.0), put 1 h, then Among them, 1.0 g of polyethylene imine was added, 40 ° C constant temperature was oscillated for 10 h, and after the reaction was completed, washed with pH 8.0 by the buffer until the filtrate was not tetrabenzenesulfonic acid reaction (TNBS). Wash with dis...

Embodiment 2

[0105] Example 2 Preparation method of probiotics microcapsules, including the following steps:

[0106] In the same embodiment, the difference is that step (12): repeating the above two steps until the 4-layer layer layer self-assembled probiotic microcapsules are assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com