Composite bulletproof plate and coating method

A ballistic plate and cladding technology, applied in chemical instruments and methods, protective clothing, protective equipment, etc., can solve the problems of complex molding process, low production efficiency, large back plate, etc., to reduce process steps, improve production efficiency, The effect of simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

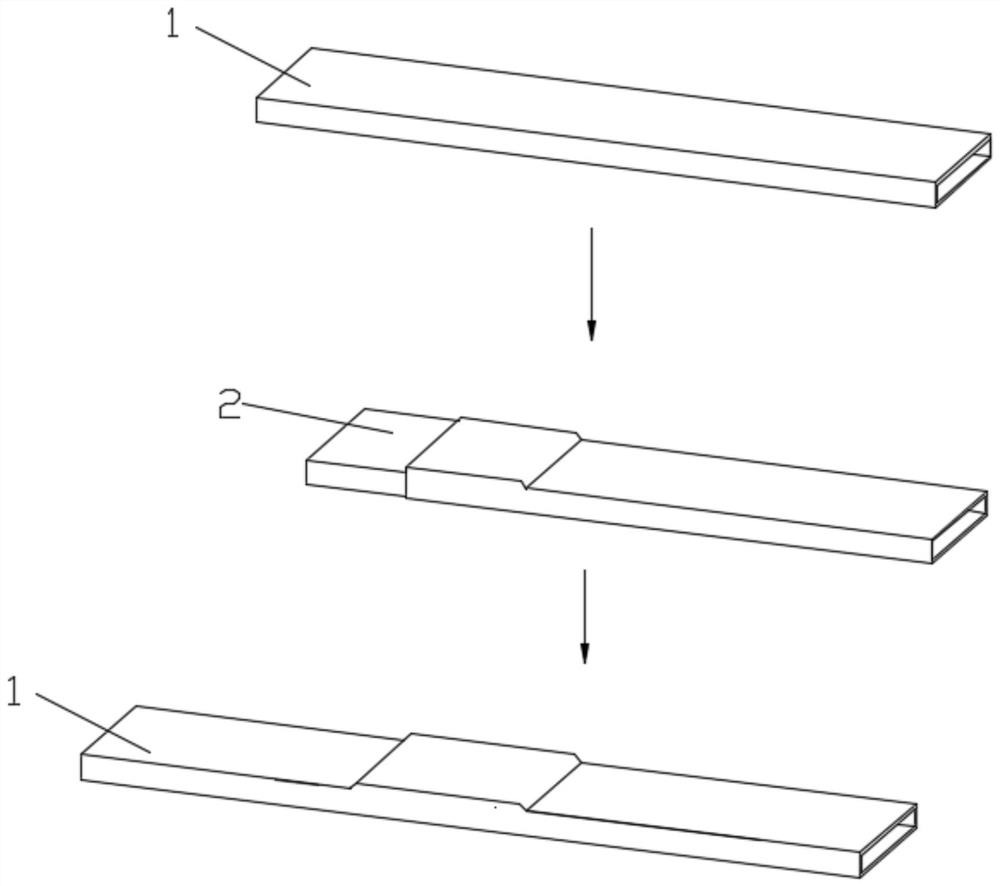

Method used

Image

Examples

Embodiment 1

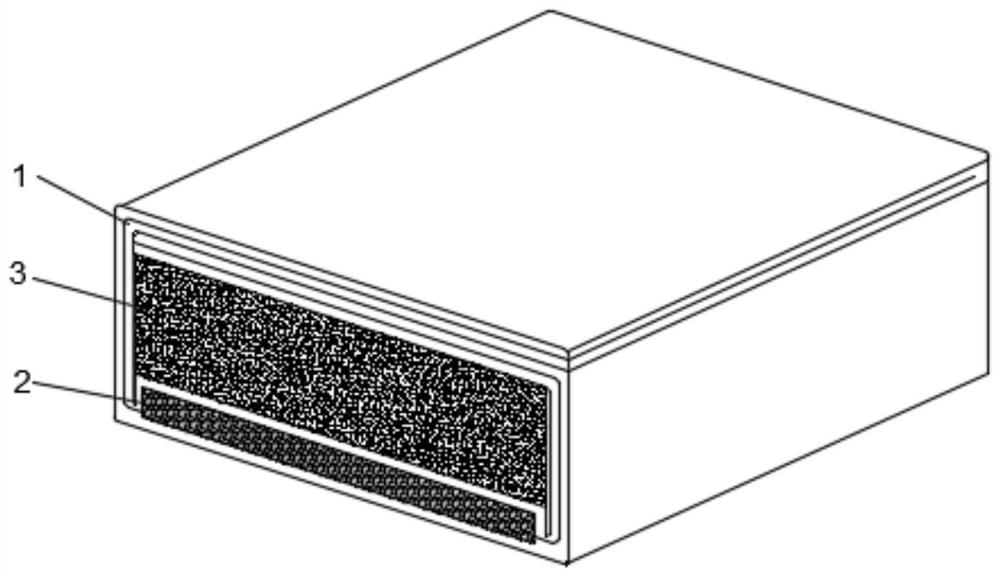

[0035] A composite bulletproof plate, such as figure 2 As shown, it includes a tubular anti-crack fabric and a ceramic plate wrapped in the tubular anti-crack fabric. The coated ceramic plate is located in the middle of the tubular anti-crack fabric. The reserved end of the material backboard; the inner and outer surfaces of the tubular anti-crack fabric are coated with a hot-melt adhesive film, and a composite material backboard is arranged above the ceramic plate.

[0036] The composite material backplane is placed above the ceramic plate and corresponds to the position of the ceramic plate, and the reserved ends at both ends of the tubular anti-crack fabric are fixed on the upper surface of the composite material backplane by high-temperature adhesive tape. The overall covering of the ceramic plate and the covering of the four peripheral surfaces of the composite material back plate are formed by the tubular anti-crack fabric, while a layer of crack-stop fabric between the...

Embodiment 2

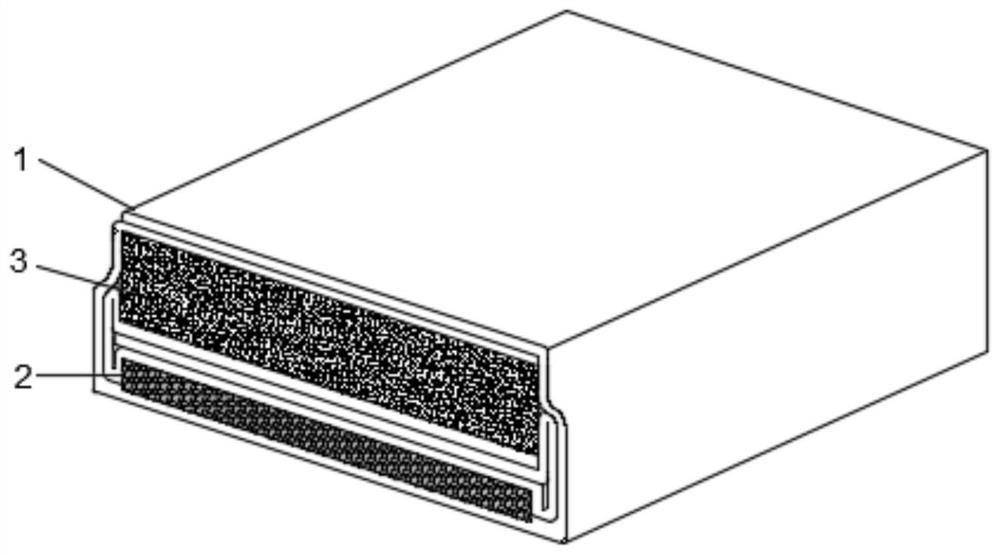

[0044] A composite bulletproof plate, such as image 3 As shown, it includes a tubular anti-crack fabric and a ceramic plate wrapped in the tubular anti-crack fabric. The coated ceramic plate is located in the middle of the tubular anti-crack fabric. The reserved end of the material backboard; the inner and outer surfaces of the tubular anti-crack fabric are coated with a hot-melt adhesive film, and a composite material backboard is arranged above the ceramic plate.

[0045] The composite material backboard is placed above the ceramic board and corresponds to the position of the ceramic board, and the reserved ends at both ends of the tubular anti-crack fabric are sequentially nested on the surface of the composite material backboard. The overall coverage of the ceramic plate and the composite material back plate is formed by the tubular anti-crack fabric, and the three-layer anti-crack fabric between the ceramic plate and the composite material back plate forms a transition l...

Embodiment 3

[0053] A composite bulletproof plate, such as Figure 4 As shown, it includes a tubular anti-crack fabric and a ceramic plate wrapped in the tubular anti-crack fabric. The coated ceramic plate is located in the middle of the tubular anti-crack fabric. The reserved end of the material backboard; the inner and outer surfaces of the tubular anti-crack fabric are coated with a hot-melt adhesive film, and a composite material backboard is arranged above the ceramic plate.

[0054] The composite material back plate is placed above the ceramic plate and corresponds to the position of the ceramic plate. Both ends of the tubular anti-crack fabric are folded and covered on the top of the ceramic plate, and then the composite material back plate is placed on the tubular anti-crack fabric. above the cracked fabric. The full coverage of the ceramic plate is formed by a tubular anti-crack fabric, while five layers of anti-crack fabric form the transition layer between the ceramic plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com