Manufacturing method of copper-plated porcelain

A production method and technology of porcelain, which is applied in the field of production of copper-inlaid porcelain, can solve problems such as the complexity of the porcelain process, and achieve the effects of good toughness, less processing steps, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

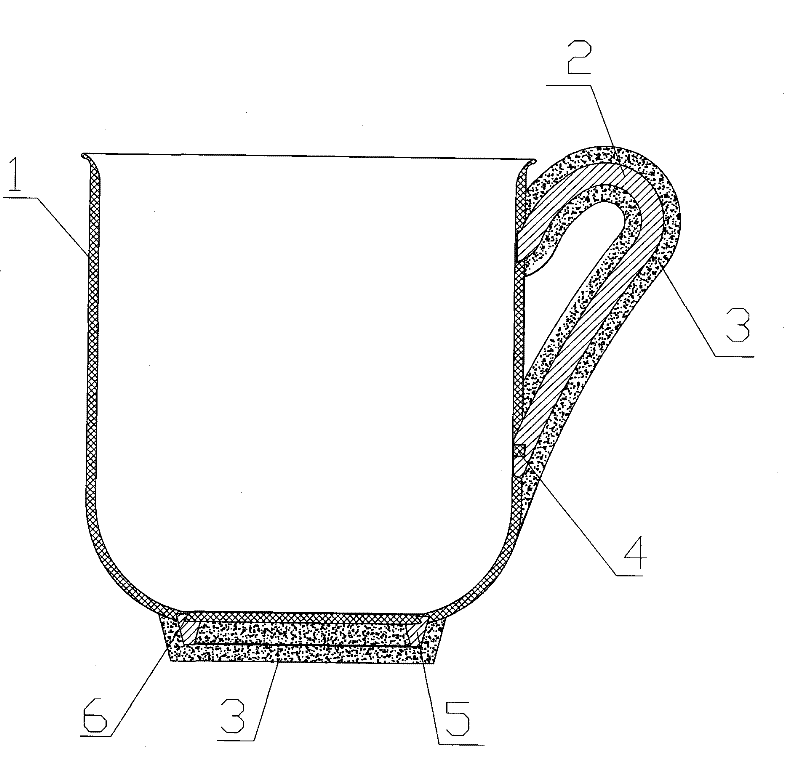

[0008] The manufacturing method of the present invention will be described in detail below by taking the copper inlaid handle and the copper base porcelain cup as examples.

[0009] Such as figure 1 As shown, the copper handle 2 and the copper base 5 of the teacup are processed separately first, and the copper handle 2 and the copper base 5 are wrapped with complex molding sand resistant to high temperature of 2000°C, and a complex molding sand protective layer 3 is formed on the surface of the copper piece. Remove the complex molding sand at both ends of the handle and the inner side of the base at the junction of the cup mud tire 1, then insert the handle 2 and base 5 into the cup mud tire 1, and completely close the mud tire 1 and the complex molding sand protective layer 3 without leaving any gaps , After the mud tire is dry, it is fired. In this way, part of the molten copper water between the complex molding sand protective layer and the porcelain body will not overflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com