Three-functional-group hyperbranched polysiloxane cross-linked high-strength and high-toughness composite hydrogel and preparation method thereof

A composite hydrogel and polysiloxane technology, applied in the field of polymer materials, can solve the problem that the mechanical properties of hydrogel cannot be strengthened and toughened, the strength and toughness of hydrogel cannot be effectively balanced, and the mechanical properties of hydrogel cannot be effectively balanced. Problems such as performance enhancement and imbalance between parameters, to achieve the effects of controllable group designability, excellent low toxicity, and strong group designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

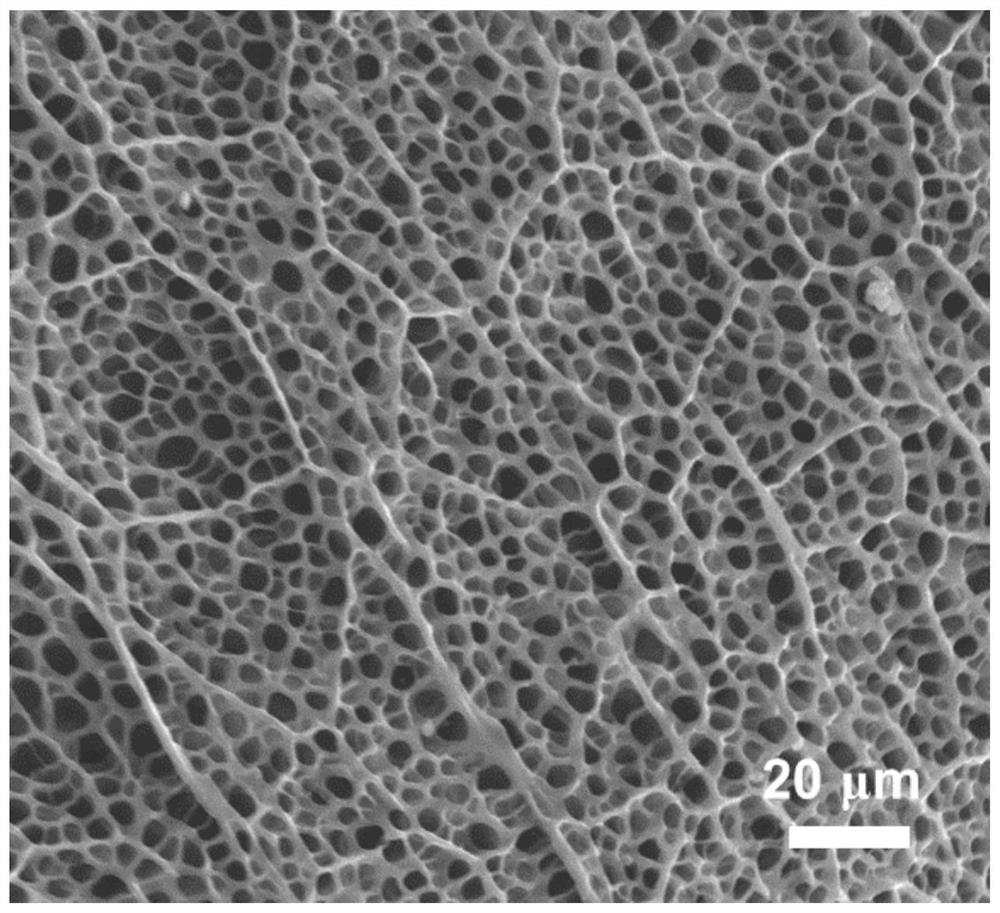

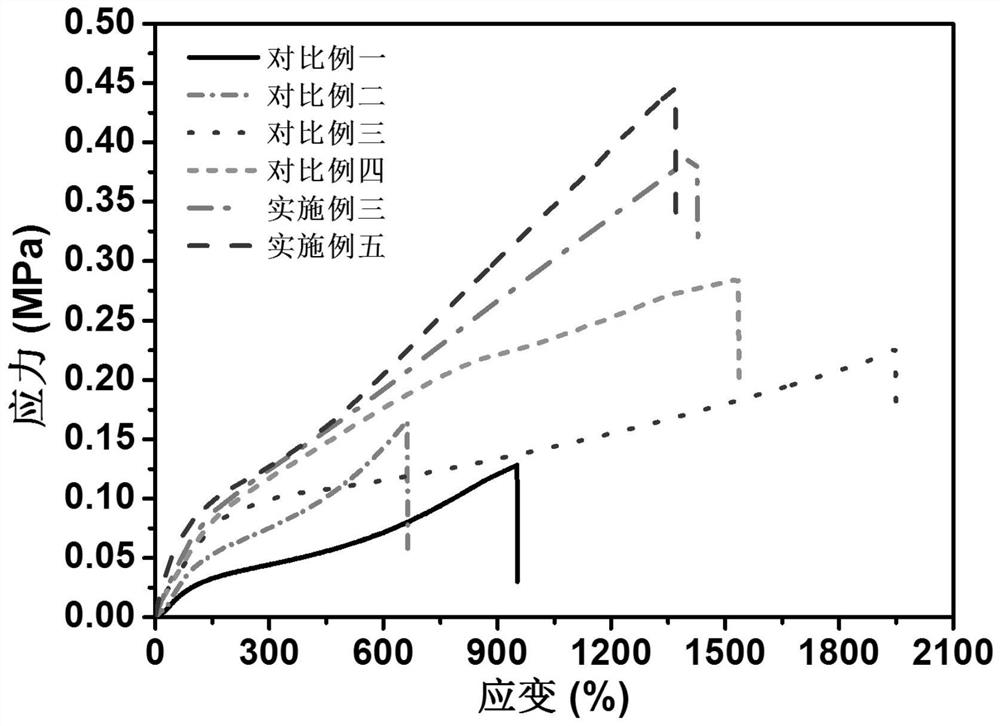

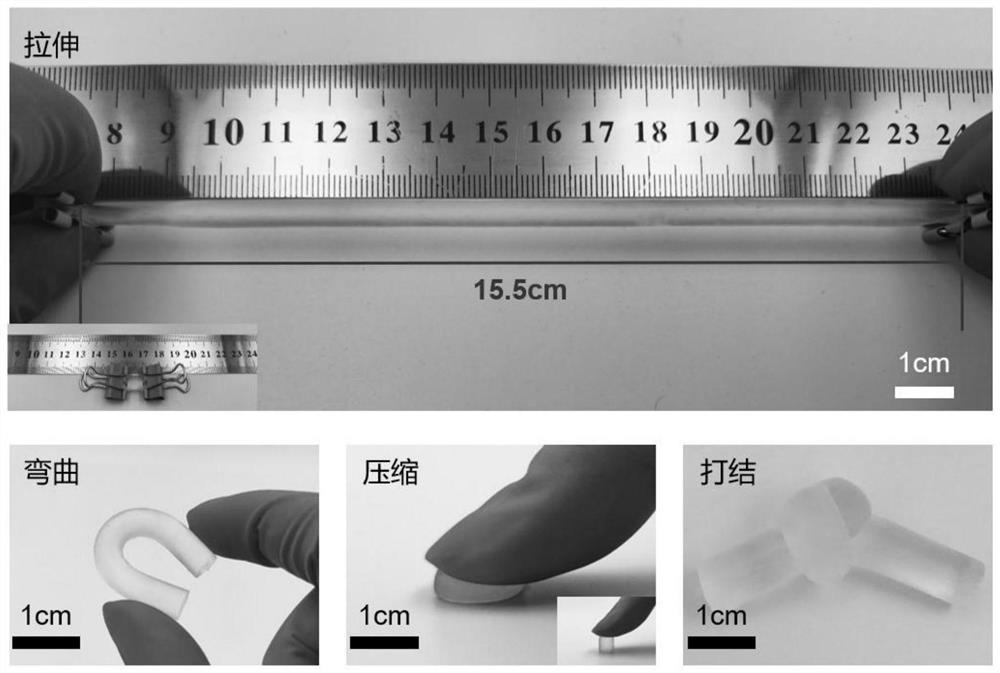

Image

Examples

Embodiment 1

[0036] 1) Preparation of hyperbranched polysiloxane containing vinyl, epoxy and alkyl groups simultaneously.

[0037] In molar ratio, mix 1mol of γ-methacryloxypropyltrimethoxysilane, 0.3mol of 3-glycidyl etheroxypropyltrimethoxysilane, 0.4mol of methyltrimethoxysilane with 2.3 mol of distilled water was mixed evenly, and 8 mol of absolute ethanol was added, and then hydrochloric acid was slowly added dropwise under stirring condition to adjust the pH value of the solution to 3; Vacuum-dried to obtain a hyperbranched polysiloxane containing vinyl, epoxy and alkyl groups.

[0038] 2) By weight, add 1 g of phosphorylated cellulose nanofibril solution with an aspect ratio of 30:1 and 11 g of N-isopropylacrylamide into a container at room temperature, add 60 ml of water, and mix to form a uniform solution.

[0039] 3) Add 0.2 ml of the hyperbranched polysiloxane prepared in step 1) and 1.1 mg of potassium persulfate to the solution obtained in step 2) in an ice bath, and stir to ...

Embodiment 2

[0041] 1) Preparation of hyperbranched polysiloxane containing vinyl, epoxy and alkyl groups simultaneously.

[0042] In molar ratio, mix 0.5mol of vinyltrimethoxysilane, 0.2mol of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 0.15mol of methyltrimethoxysilane with 1.5 mol of distilled water was mixed evenly, and 4 mol of absolute ethanol was added, and then acetic acid was slowly added dropwise under stirring condition to adjust the pH value of the solution to 4; Vacuum-dried to obtain a hyperbranched polysiloxane containing vinyl, epoxy and alkyl groups.

[0043] 2) By weight, add 1 g of hydroxylated cellulose nanofibrils with an aspect ratio of 20:1 and 30 g of N-methylolacrylamide into a container at room temperature, add 150 ml of water, and mix to form a uniform solution.

[0044] 3) Add 0.2ml of the hyperbranched polysiloxane prepared in step 1) and 0.5mg of potassium persulfate to the solution obtained in step 2) in an ice bath, and stir to form a uniform solution. R...

Embodiment 3

[0046] 1) Preparation of hyperbranched polysiloxane containing vinyl, epoxy and alkyl groups simultaneously.

[0047] In molar ratio, 1mol of γ-methacryloxypropyltriethoxysilane, 0.35mol of 3-glycidyl etheroxypropyltrimethoxysilane, 0.35mol of propyltrimethoxysilane and Mix 2.6 mol of distilled water evenly, add 6.8 mol of absolute ethanol, then slowly add p-toluenesulfonic acid dropwise under stirring condition to adjust the pH of the solution to 5; after the dropwise addition, raise the temperature to 42°C, and react under nitrogen protection for 5 hours; After the reaction is completed, the hyperbranched polysiloxane containing vinyl groups, epoxy groups and alkyl groups is obtained through vacuum drying.

[0048] 2) By weight, add 1 g of phosphorylated cellulose nanofibrils with an aspect ratio of 60:1 and 55 g of N-isopropylacrylamide into a container at room temperature, add 190 ml of water, and mix to form a uniform solution.

[0049] 3) Add 0.2ml of the hyperbranched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com