Composite material with light transmittance changing along with humidity, preparation method of composite material and visual humidity-sensitive sensing film

A humidity change, composite material technology, applied in transmittance measurement, phase influence characteristic measurement, etc., can solve the problems of wearable clothing application with external wires, inflexibility, and few humidity sensors, and achieve the effect of visual monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]The present invention also provides a preparation method of a composite material whose light transmittance changes with humidity, comprising the steps of:

[0037] S1. preparing a porous membrane substrate;

[0038] S2. The porous membrane base material prepared in step S1 is immersed in an organic acid solution for a preset time and then taken out to obtain a composite membrane material; specifically: prepare a certain mass fraction of an organic acid aqueous solution under acidic conditions and pour it into a petri dish Then cut the nanofiber film to a specific size (select the appropriate size according to the size of the petri dish), place it in an organic acid aqueous solution and soak it for a period of time, and take it out of the petri dish after the film is evenly infiltrated.

[0039] S3. Heat-treating the composite film material in step S2 to obtain a composite material whose light transmittance varies with humidity.

[0040] In step S1, the porous membrane s...

Embodiment 1-5

[0049] A composite material whose light transmittance changes with humidity is prepared by the following steps:

[0050] S1. Polyethylene-vinyl alcohol nanofibers (PVA-PE) were prepared by melt extrusion phase separation, and nanofiber suspensions were prepared into independent flexible nanofiber films by high-pressure spraying.

[0051] S2. Prepare 50ml of citric acid aqueous solution with a mass fraction of 15wt% under acidic conditions, pour it into a petri dish with an outer diameter of 9cm, and then cut the polyethylene-vinyl alcohol nanofiber film with a thickness of 30μm into a rectangle of 2cm*2cm , placed in citric acid aqueous solution for continuous soaking for 4 hours, and removed from the petri dish after the film was soaked evenly.

[0052] S3. The taken-out film is subjected to high-temperature treatment in different temperature environments for 3 minutes, and the composite film is obtained after drying.

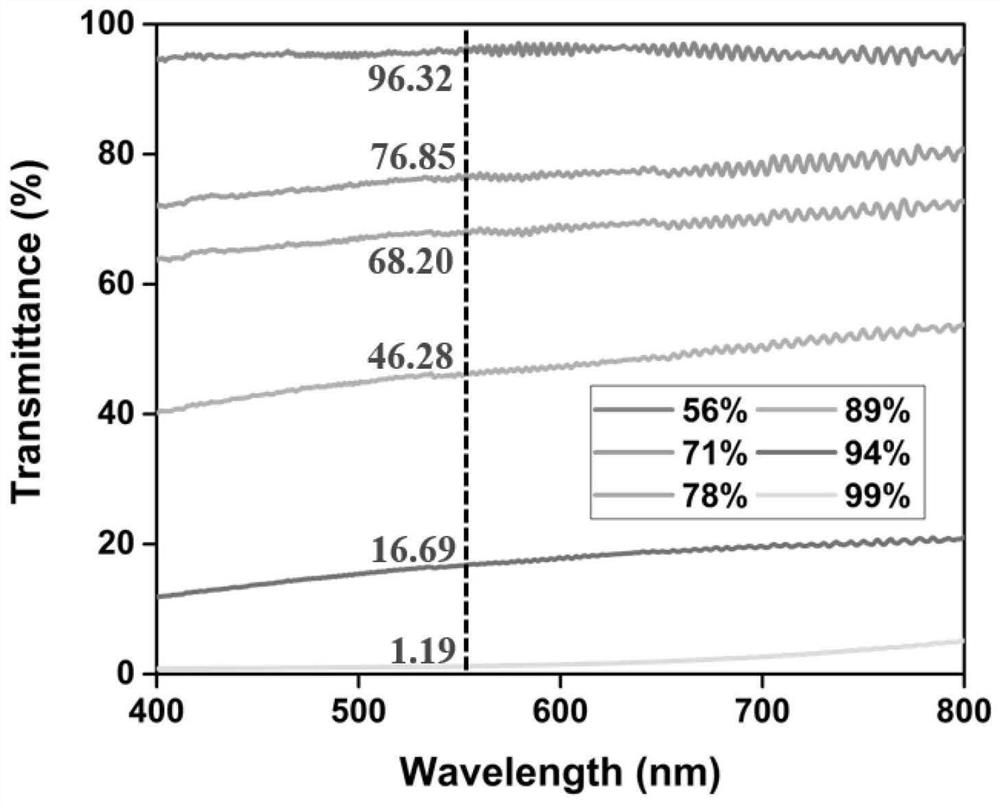

[0053] The test humidity of the light transmittance in ...

Embodiment 6-10

[0062] A composite material whose light transmittance changes with humidity. Compared with Example 5, the difference is that the types of fibers and organic acids are shown in Table 2, and the others are the same as Example 5, and will not be repeated here.

[0063] Preparation conditions and performance test results of table 2 embodiment 6-10

[0064]

[0065]

[0066] It can be seen from Table 2 that the fiber substrate and the type of organic acid will have a certain impact on the tensile properties and optical transparency of the composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com