Organic hafnium compound content detection pretreatment method

A hafnium compound and organic technology, which is applied in the pre-treatment field of content detection of organic hafnium compounds, can solve problems such as excessive content of matrix substances, detection background signal interference, low accuracy and effectiveness of instrument testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

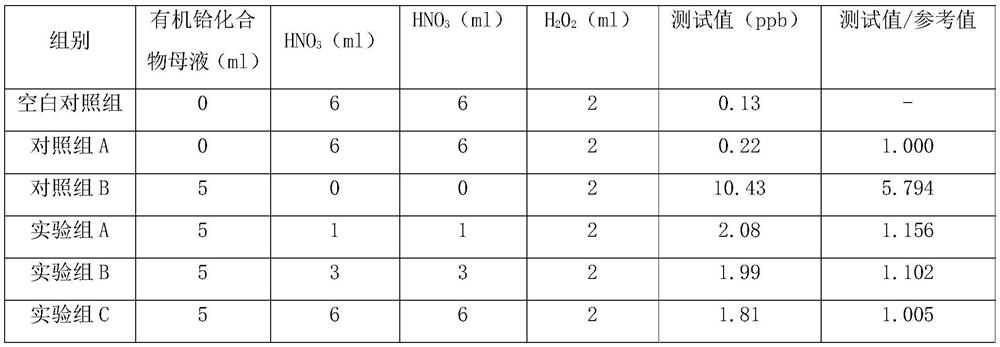

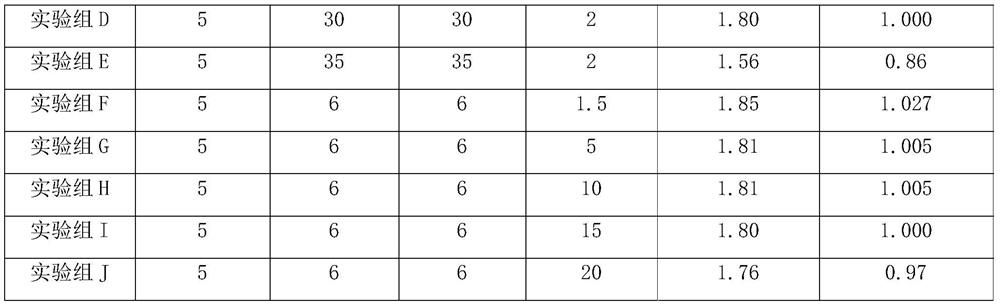

Examples

Embodiment 1

[0023] Step 1: Prepare a cleaned PFA digestion tank with a cover. Use a pipette gun to add the mother liquor of the organic hafnium compound into the digestion tank. Place the digestion tank on a temperature-controllable heating plate at a heating temperature of 50°C. The mouth is heated and concentrated to half of the total volume to obtain the processed product 1;

[0024] Step 2: Turn off the power supply of the heating plate, take off the digestion tank after cooling for a period of time and continue to cool to room temperature, add 30% by mass percent of superior grade pure nitric acid and 30 percent by mass percent of superior grade nitric acid to the concentrated product Pure hydrogen peroxide, the volume ratio of the addition of the nitric acid to the addition of the organic hafnium compound mother liquor is 3:5, the volume ratio of the addition of the hydrogen peroxide to the addition of the organic hafnium compound mother liquor is 3:1, the Put the digestion tank on ...

Embodiment 2

[0027] Step 1 is the same as Example 1, except that the heating temperature is 60°C;

[0028] Step 2: Turn off the power supply of the heating plate, take off the digestion tank after cooling for a period of time and continue to cool to room temperature, add 30% by mass percent of superior grade pure nitric acid and 30 percent by mass percent of superior grade nitric acid to the concentrated product Pure hydrogen peroxide, the volume ratio of the addition of the nitric acid to the addition of the organic hafnium compound mother liquor is 6:1, the volume ratio of the addition of the hydrogen peroxide to the addition of the organic hafnium compound mother liquor is 1:3, the Put the digestion tank on the electric heating plate, turn on the power button, heat the reaction and concentrate it to less than one-third of the total volume, the heating temperature is 90°C, remove the digestion tank from the electric heating plate, and cool it at room temperature to obtain a processed prod...

Embodiment 3

[0031] Step 1 is the same as Example 1, except that the heating temperature is 70°C;

[0032] Step 2: Turn off the power supply of the heating plate, take off the digestion tank after cooling for a period of time and continue to cool to room temperature, add 30%-40% high-quality pure nitric acid and 30% by mass to the concentrated product The superior grade pure hydrogen peroxide, the volume ratio of the addition of the nitric acid and the addition of the organic hafnium compound mother liquor is 3:1, the volume ratio of the addition of the hydrogen peroxide and the addition of the organic hafnium compound mother liquor is 1: 1. Put the digestion tank on the electric heating plate, turn on the power button, heat the reaction to concentrate to less than one-third of the total volume, the heating temperature is 120°C, remove the digestion tank from the electric heating plate, and cool it at room temperature to obtain Handle product one;

[0033] Step 3 is the same as in Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com