Axial force conical surface thrust structure for high-speed heavy-load helical gear transmission system

A transmission system and helical gear technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of high operating temperature, thrust bearings not suitable for pinion operating conditions, and oil film rupture of conical thrust rings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below with reference to the accompanying drawings:

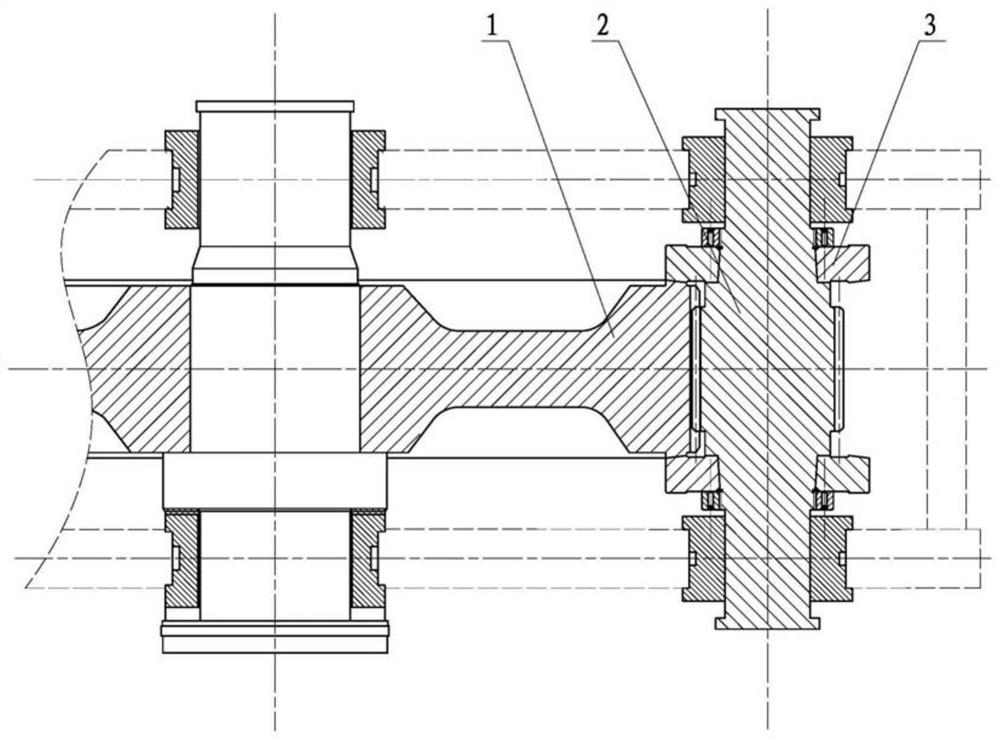

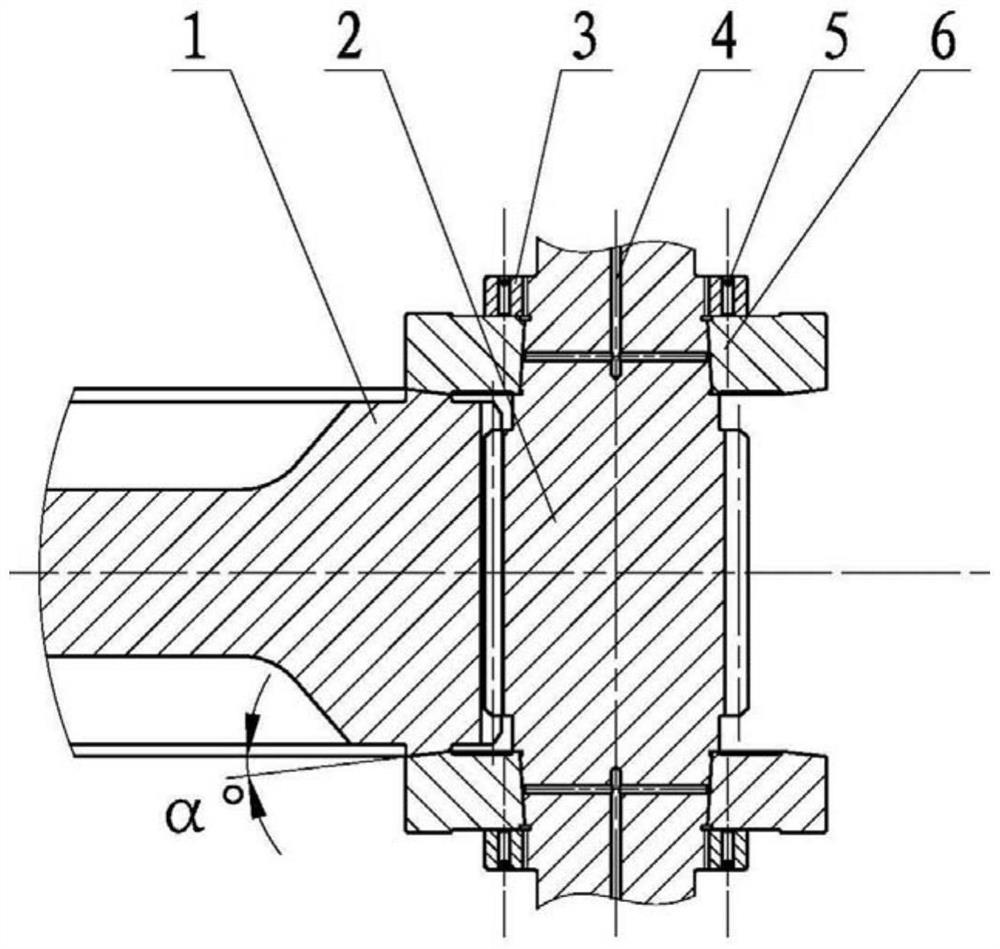

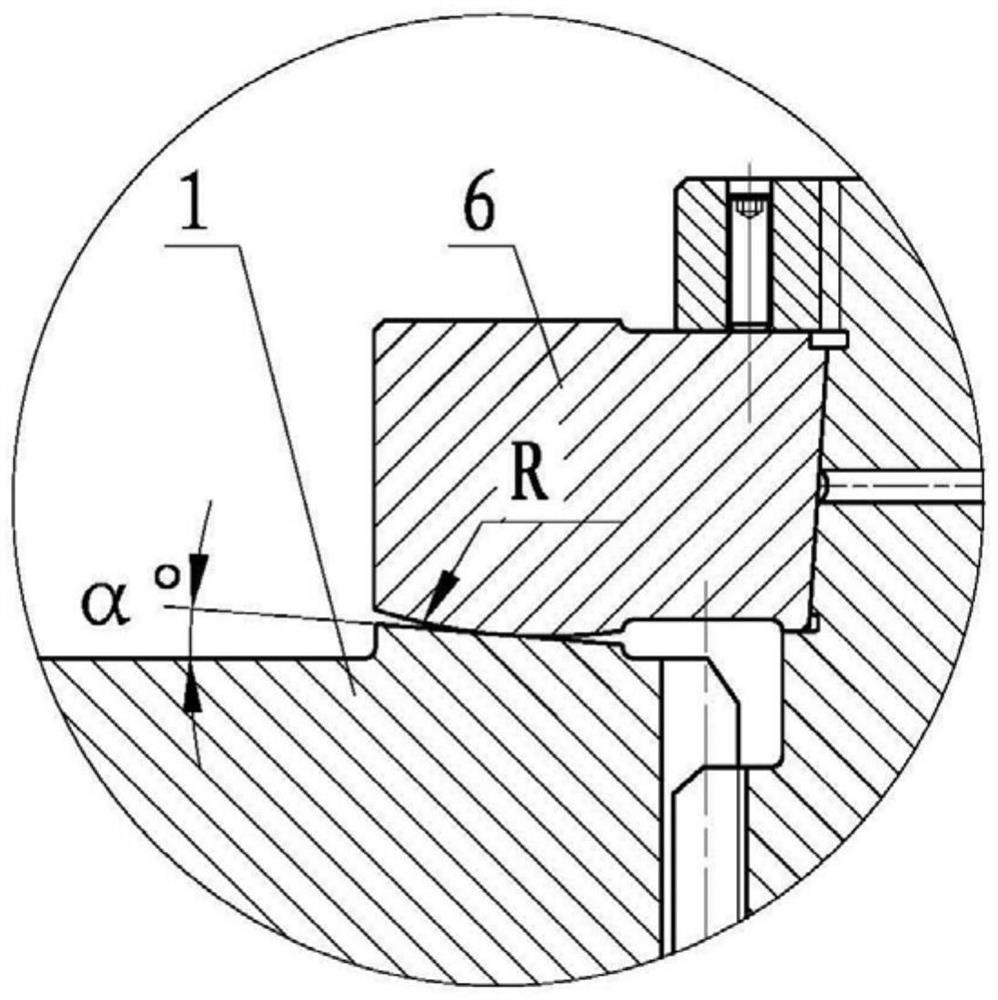

[0017] Combine Figure 1-3 The axial force cone surface thrust structure of the present invention is composed of a low speed large gear 1, a high speed pinion 2, an axial lock nut 3, a high pressure oil passage 4, a tightening screw 5, a cone surface push ring 6. The cone surface push ring 6 is a tapered structure, fitted to the outer diameter portion of the high speed pinion 2 tapered surface, and the high-pressure oil passage 4 is provided inside the high speed pinion, and the high pressure oil pump is passed through the high pressure oil pump. Injecting the insertion of the jaw high pressure oil passage 4, the inner diameter of the cone surface push loop 6 is large, and the tapered push loop 6 is tightly contacted with the high-speed gear shaft by mating the tightening axis 6, and since the high pressure oil generates internal pressure. The inner diameter of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com