Quenching furnace with impurity removal function

A quenching furnace and function technology, applied in the field of quenching furnaces, can solve the problems of reducing the reliability of the quenching furnace, easily scalding the staff, and reducing the quality of the quenching liquid, so as to achieve reuse, improve safety and reliability, and improve energy saving and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

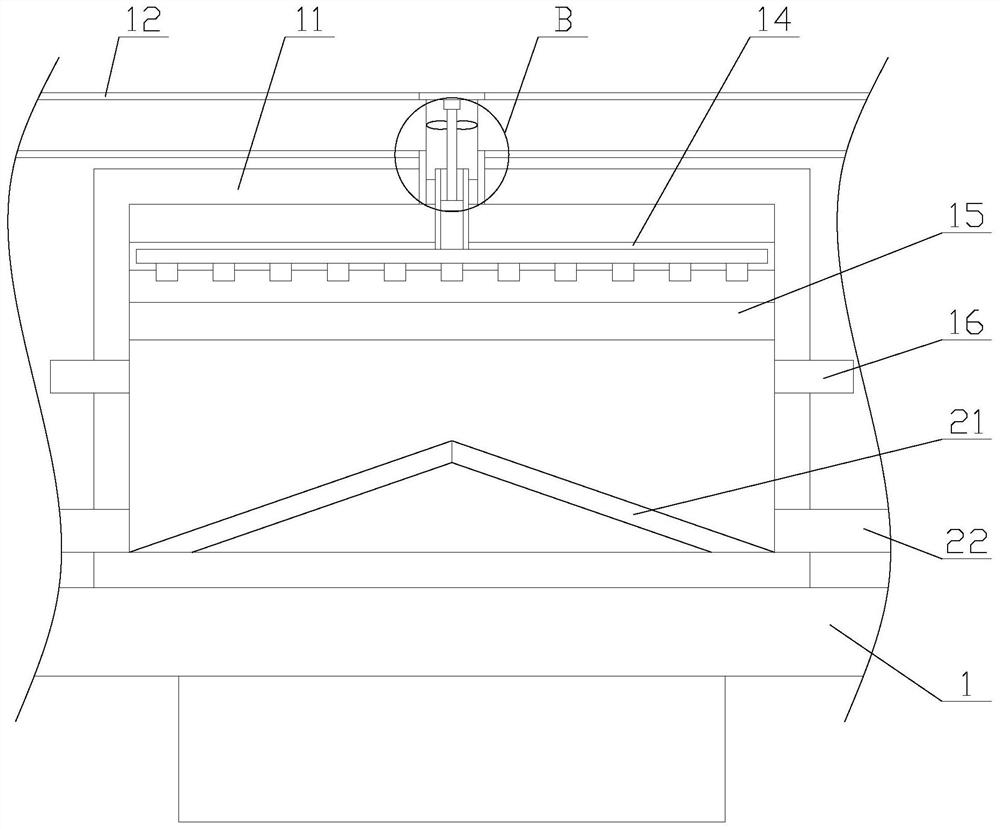

[0021] The invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

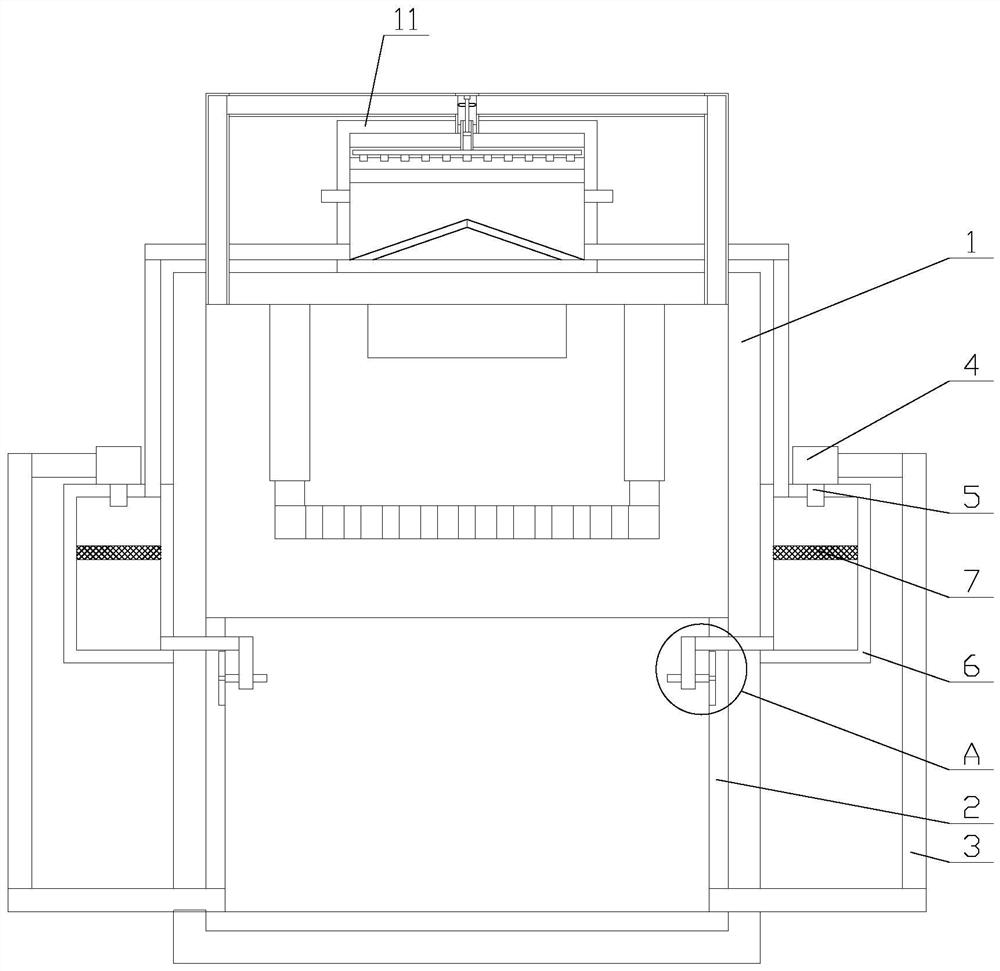

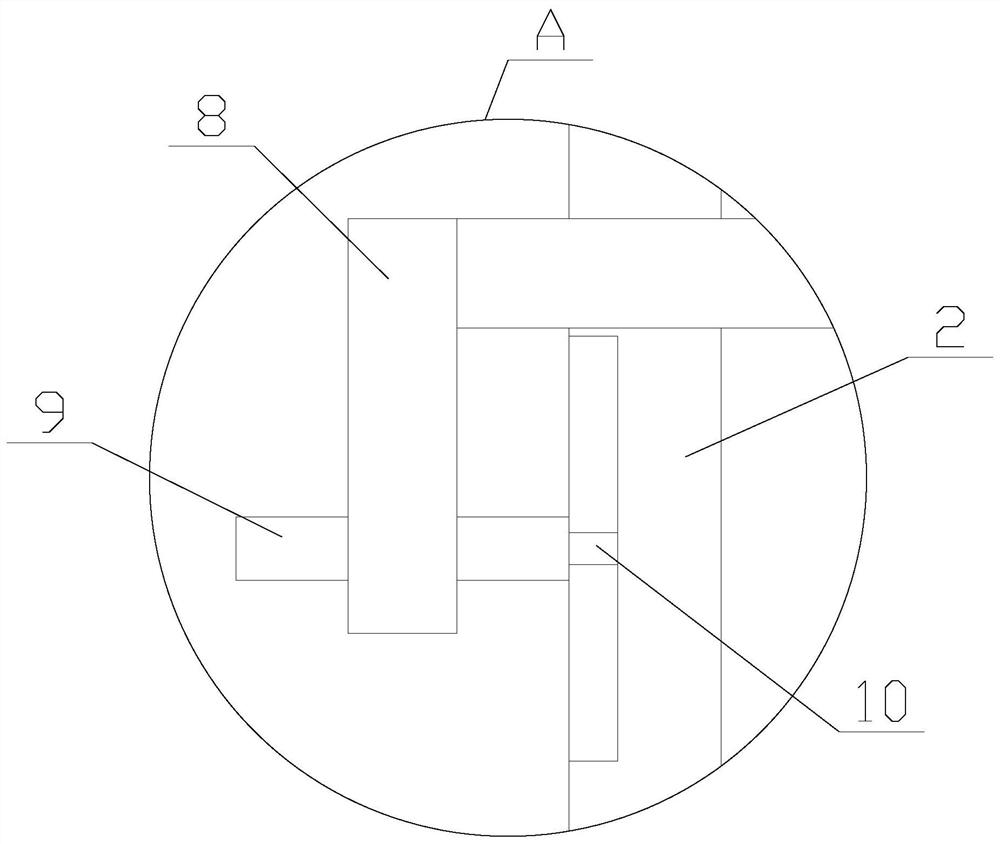

[0022] like figure 1 As shown, a quenching furnace having a mixed function, including the body 1, the quenching box 2, and the quenching device, the quenching device being disposed on the top of the main body 1, the quenching box 2 is disposed at the bottom of the main body 1, also Including a cooling mechanism and two developing agencies, the two developing mechanisms are disposed on both sides of the body 1, and the cooling mechanism is disposed above the main body 1, the cooling mechanism is connected to the developing mechanism, the main body 1 PLC is provided inside;

[0023] PLC, programs programmable logic controller, generally used for processing and output of the data, and is used to implement central control. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com