A kind of photocuring coating and its preparation method and application

A technology of light-curing coatings and raw materials, applied in polyurea/polyurethane coatings, coatings, chemical industries, etc., can solve problems such as poor adhesion and poor bending resistance, achieve high solid content, improve hydrophilicity, and reduce equipment input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a light-cured coating, the raw materials of which include 20kg of hyperbranched polyglycerol acrylate, 30kg of urethane acrylate, 20kg of trimethylolpropane triacrylate, 5kg of 1-hydroxycyclohexylacetophenone, 0.5kg of Foaming agent and 0.5kg leveling agent.

[0036] The preparation method of the above-mentioned light-curing coating includes: obtaining the light-curing coating after mixing all the raw materials uniformly.

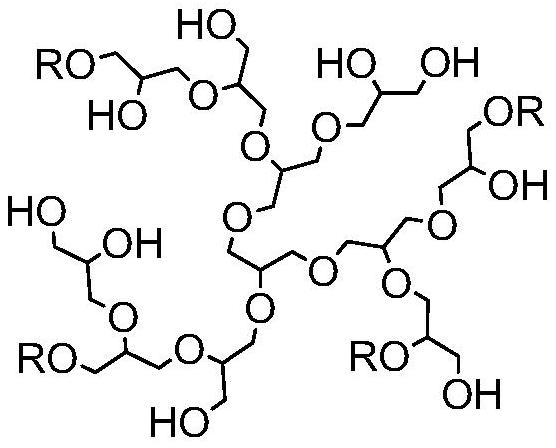

[0037] Wherein, the preparation method of hyperbranched polyglycerol acrylate comprises the following steps: mixing 200g hyperbranched polyglycerol with a molecular weight of 2000, 890g methyl acrylate and 5.05g tetrabutyl titanate, refluxing at 100° C., fractionating methanol through a rectifying column, After 6 hours of reaction, excess methyl acrylate was distilled off to obtain hyperbranched polyglycerol acrylate, wherein the saponification value of hyperbranched polyglycerol acrylate was 83.2 mg / g.

Embodiment 2

[0039] This embodiment provides a light-curing coating, the raw materials of which include 15kg of hyperbranched polyglycerol acrylate, 25kg of urethane acrylate, 20kg of polyethylene glycol 400 diacrylate, 23kg of ethoxylated trimethylolpropane triacrylate, 7kg 2-methyl-2-hydroxy-1-phenylacetone, 0.5kg defoamer and 0.5kg leveling agent.

[0040] The preparation method of the above-mentioned light-curing coating includes: obtaining the light-curing coating after mixing all the raw materials uniformly.

[0041]Wherein, the preparation method of hyperbranched polyglycerol acrylate comprises: mixing 300g hyperbranched polyglycerol with a molecular weight of 3000, 1335g methyl acrylate and 6.23g tetrabutyl titanate, refluxing at 100° C., fractionating methanol through a rectifying column, After 6 hours of reaction, excess methyl acrylate was distilled off to obtain hyperbranched polyglycerol acrylate, wherein the saponification value of hyperbranched polyglycerol acrylate was 112....

Embodiment 3

[0043] This embodiment provides a light-curing coating, the raw materials of which include 15kg of hyperbranched polyglycerol acrylate, 25kg of urethane acrylate, 20kg of polyethylene glycol 400 diacrylate, 23kg of ethoxylated trimethylolpropane triacrylate, 7kg 1-hydroxycyclohexylacetophenone, 0.5kg defoamer and 0.5kg leveling agent.

[0044] The preparation method of the above-mentioned light-curing coating includes: obtaining the light-curing coating after mixing all the raw materials uniformly.

[0045] Wherein, the preparation method of hyperbranched polyglycerol acrylate comprises: mixing 200g hyperbranched polyglycerol with a molecular weight of 4000, 670g methyl acrylate and 3.5g triethylamine, refluxing at 100°C, fractionating methanol through a rectifying column, and reacting for 6h Then, excess methyl acrylate is distilled off to obtain hyperbranched polyglycerol acrylate, wherein the saponification value of hyperbranched polyglycerol acrylate is 90.9 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com