Biodegradable salt-resistant thickening system as well as preparation method and application thereof

A biodegradable and systematic technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as temperature resistance, poor salt resistance, formation damage, difficult to handle flowback fluid, etc., to achieve convenient and flexible use Compounding, damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare the biodegradable salt-tolerant thickening system of the present invention:

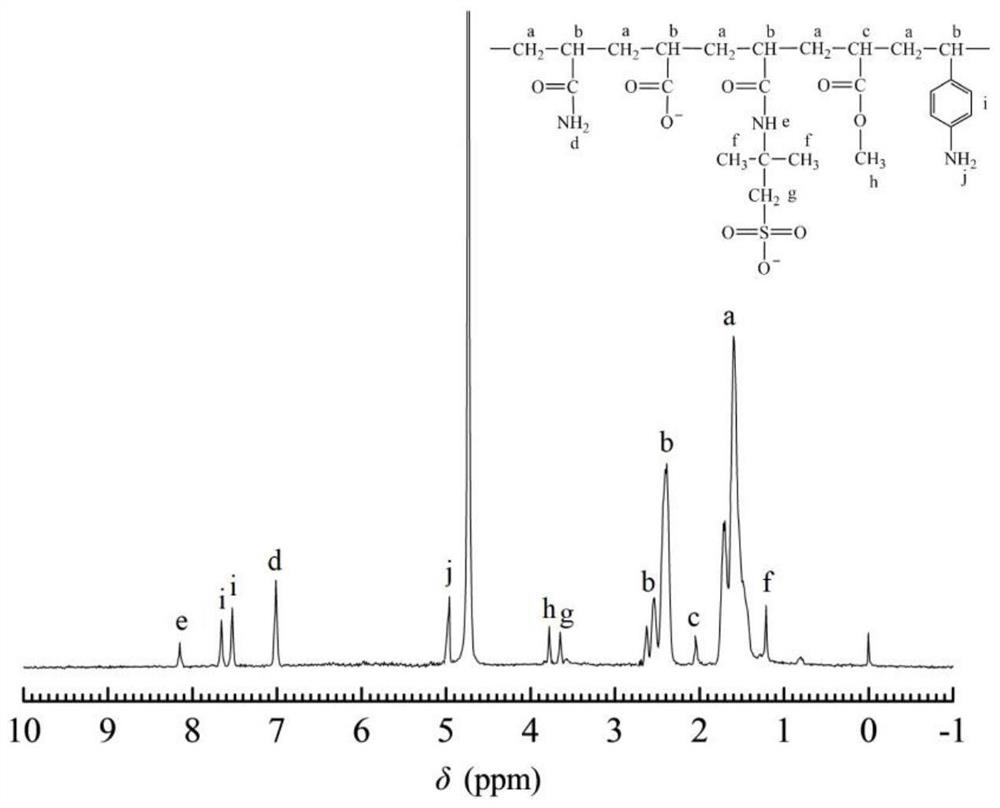

[0057] 1.1 Preparation of biodegradable salt-tolerant polymer

[0058] Accurately weigh acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and vinyl acetate with a molar ratio of 38:20:2:40 and dissolve them in a certain amount of deionized water. The mass concentration of the monomers is 30%, and then placed in a 250mL three-neck flask, stirring constantly to dissolve it. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear. Inject the initiator azobisisobutyronitrile (AIBN) with a syringe, and the amount of the initiator is 0.1% of the total mass of the monomers. The temperature was raised to 43°C, and the N 2 Stir continuously, seal the three-necked flask and place it for 6 hours, and finally obtain a transparent gel-like product, take it out and cut it into small pieces, purify it w...

Embodiment 2

[0066] Prepare the biodegradable salt-tolerant thickening system of the present invention:

[0067] 2.1 Preparation of biodegradable salt-tolerant polymer

[0068] Accurately weigh acrylamide, acrylic acid, carboxybetaine methacrylic acid and acrylate with a molar ratio of 47:15:3:35, dissolve them in a certain amount of deionized water, the mass concentration of the monomers is 20%, and then place in 250mL In a three-necked flask, stir continuously to dissolve it. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear, cooled to 5°C and stabilized. The initiator ammonium persulfate / sodium bisulfite mixture is injected with a syringe, and the amount of the initiator is 0.05% of the total mass of the monomers. Maintain the temperature at 5°C and continue to feed N 2 Stir continuously, seal the three-necked flask and place it for 7 hours, and finally obtain a transparent gel-like product, take it o...

Embodiment 3

[0076] Prepare the biodegradable salt-tolerant thickening system of the present invention:

[0077] 3.1 Preparation of biodegradable salt-tolerant polymer

[0078] Accurately weigh acrylamide, acrylic acid, carboxybetaine methacrylic acid and maleic anhydride with a molar ratio of 63:10:2:25, dissolve them in a certain amount of deionized water, the mass concentration of the monomers is 40%, and then place In a 250mL three-neck flask, stir continuously to dissolve it. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear, cooled to 10°C and stabilized. The initiator is the ammonium persulfate / sodium bisulfite mixed solution injected with a syringe, and the amount of the initiator is 0.07% of the total mass of the monomer. Maintain the temperature at 5°C and continue to feed N 2 Stir continuously, seal the three-neck flask and place it for 5 hours, and finally obtain a transparent gel-like produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com