Modeling method for predicting switching loss in dynamic process of IGBT

A technology of switching loss and modeling method, which is applied in the direction of calculation model, biological model, biological neural network model, etc., can solve the problems of slow prediction speed, low prediction accuracy, and slow simulation speed, so as to improve reliability and expand Strong ability and high reliability to predict the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

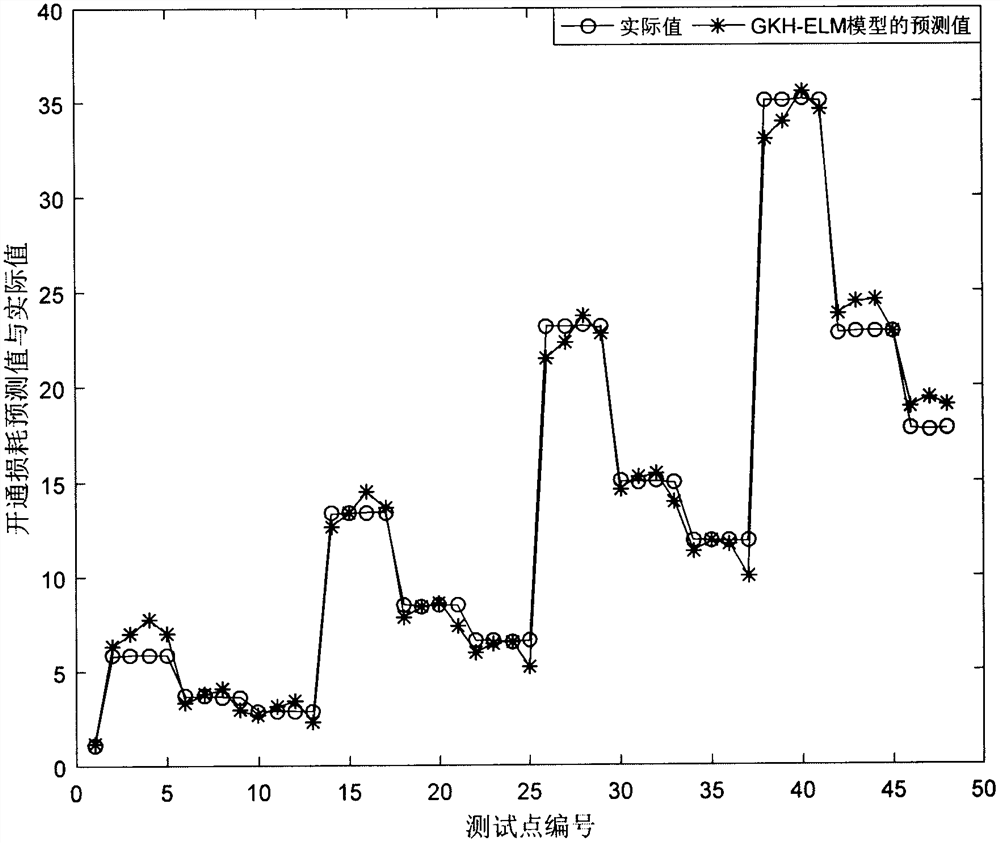

[0076] The present invention uses a PC as a platform for model building, wherein the CPU is i5-3230M 2.60GHz, the installed memory is 4GB, the operating system is Windows 7-64 bits, and MATLAB R2016a version is used. The IGBT module is MMG75S120B6HN from Macmic. The rated value of the module is 1200V / 75A. The module includes two identical IGBT chips and freewheeling diodes, and the distance between the IGBT chip and the FWD chip is 6.4 mm.

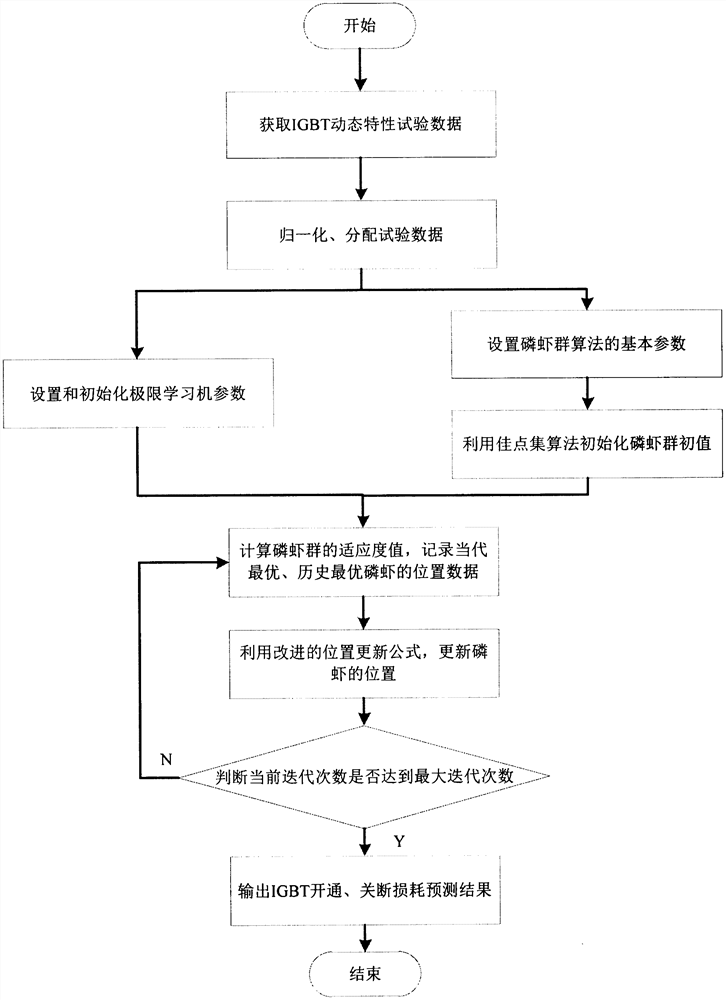

[0077] Step 1: Obtain IGBT dynamic characteristic test data

[0078] (1.1) Obtain 240 sets of test data through the IGBT dynamic characteristic test, each set of data includes DC bus voltage, collector current, gate voltage and switching frequency data, as well as the turn-on and turn-off loss data of the IGBT module;

[0079] Step 2: Normalize and distribute the IGBT dynamic characteristic test data

[0080] (2.1) Use formula (1) to normalize the IGBT characteristic test data;

[0081] (2.2) Divide the normalized test data into learning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com