Bismuth-based nano material as well as preparation method and application thereof

A nanomaterial, bismuth nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems such as the capacity and durability of bismuth-based negative electrode materials to be improved, and achieve improved electrochemical performance. Cycling performance, loss avoidance, effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 0.5 g of PAN was added to 6 ml of DMF, stirred for 12 h to obtain a solution A.

[0046] 0.49 g of a five-nitrate, 0.1 g of dithiamine and 1.2 ml of DMF were added to the centrifuge tube, stirred to clear and transparent, add solution A, and purge the centrifuge tube with 0.2 ml of DMF and add the cleaning liquid to the solution together. A. Then at 35 ° C for 35min (1000 rpm), the precursor solution was obtained.

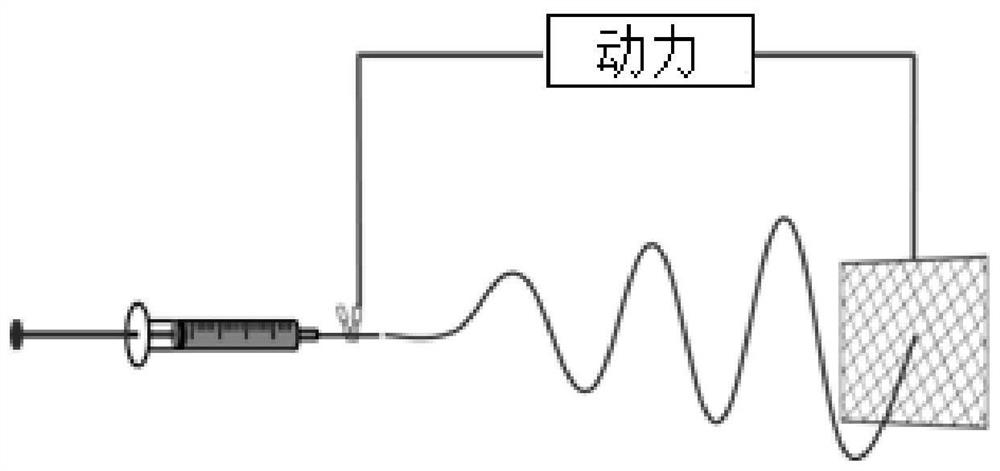

[0047] Electrostatic spun is carried out using a precursor solution. Specific electrostatic spinning operation figure 1 As shown, a 1ml syringe is used to absorb the precursor solution and a flat needle of a specification is 20 g, and then the syringe is placed in a microjet pump, and a layer of aluminum foil is placed on the roller as a collector. A 10 kV voltage is applied to the needle, and the distance from the needle tippage receiver is 12.5 cm, and the fiber material is collected after the end.

[0048] The fibrous material was removed in the porcelain boat,...

Embodiment 2

[0053] This embodiment provides a bismuth-based nanomaterial, and the solar difference of the preparation method and Example 1 is to adjust the mass of the diodide to 0.2 g.

[0054] The specific preparation method is as follows:

[0055] 0.5 g of PAN was added to 6 ml of DMF, stirred for 12 h to obtain a solution A.

[0056] 0.49 g of a five-nitrate, 0.2 g of dithiamine and 1.2 ml of DMF were added to the centrifuge tube, stirred to clear and transparent and added solution A for mixing, and was purified with 0.2 ml of DMF to clean the centrifuge tube and add the cleaning liquid to the solution together A. Then at 35 ° C for 35min (1000 rpm), the precursor solution was obtained.

[0057] Electrostatic spun is carried out using a precursor solution. Specific electrostatic spinning operation figure 1 As shown, a 1ml syringe is used to absorb the precursor solution and use a flat needle head of 20 g, and then the syringe is placed in a microjet pump. A layer of aluminum foil is place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com