Micro-inclined condenser tube bundle arrangement method capable of reducing thermal resistance

A layout method and condenser technology, applied in the direction of heat exchanger shell, steam/steam condenser, heat exchange equipment, etc., can solve the problem of reducing the heat transfer efficiency of the condenser, increasing the heat transfer resistance of the condenser tube bundle, Affect the economics and safety of the unit to achieve the effect of improving heat transfer efficiency and easy calculation and programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred implementation examples of the present invention are described below, and it should be understood that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0041] Implementation Example 1

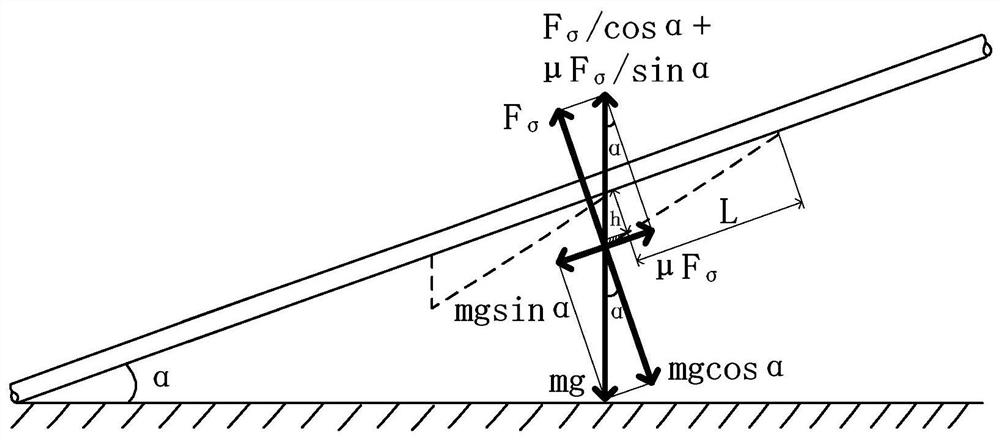

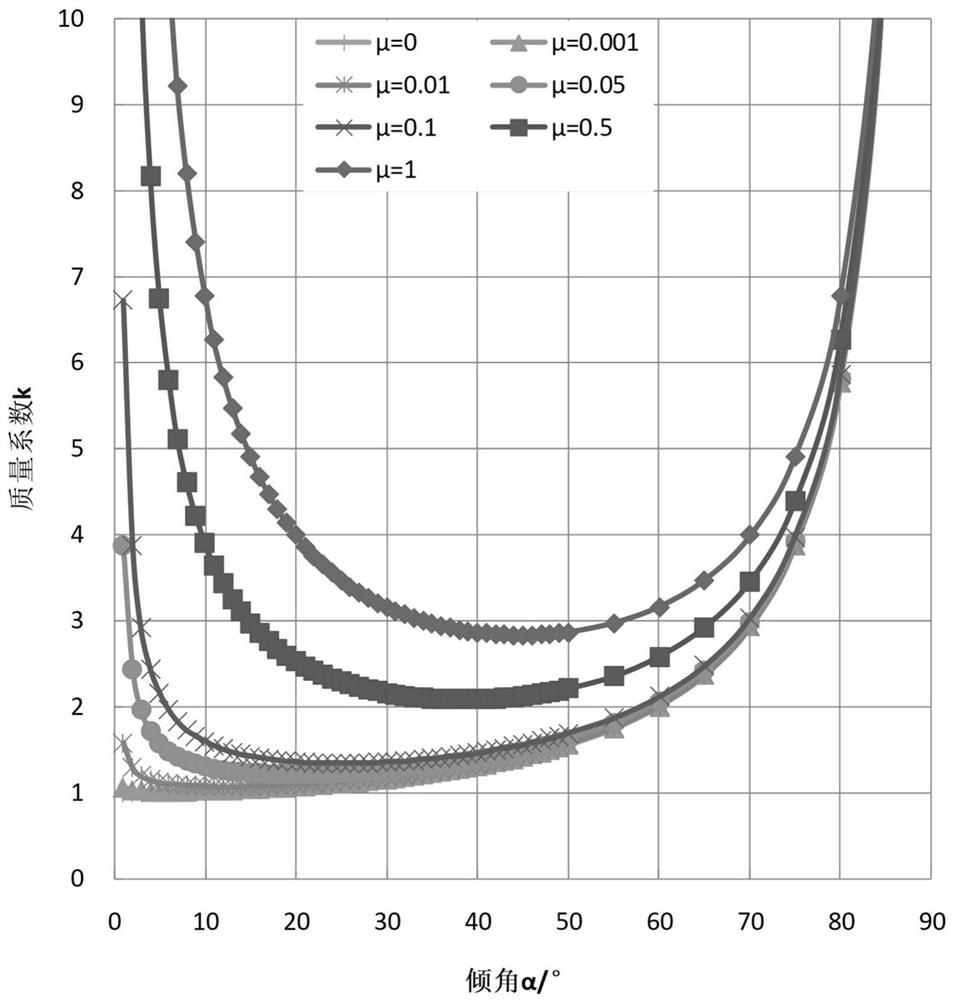

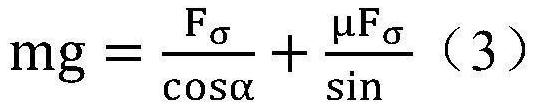

[0042] The invention provides a slightly inclined condenser tube bundle arrangement method that can reduce thermal resistance. When the condenser heat exchange tube bundle is preset at an inclination angle, the condensed water film will slide down the tube wall when it increases to the set thickness. The thickness of the water film continues to increase during the descent, and eventually it will drip. The sliding process will reduce the thickness of a part of the water film, and facilitate the flow of impurities in the tube under the action of gravity, improving the heat transfer efficiency of the heat exchange tube bundle. The specific implementation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com