A kind of preparation method of the water-based adhesive that has mutual understanding to the surface energy of the substrate

A substrate surface, mutual recognition technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc. -Object interaction force and other issues, to achieve wide practicability and improve the effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Put 1 mole of HDI trimer and 1 mole-average molecular weight of 1000 and viscosity of 2000cps monohydroxyl silicone oil into the reactor, and react at 70-80°C for 2 hours to obtain diisocyanate containing silicone side chains;

[0021] (2) 4.0wt% of polybutylene adipate diol, isophorone diisocyanate, hydrophilic chain extender dimethylol propionic acid (solid weight) of molecular weight 2000 is added to reaction vessel, control-NCO / -OH molar ratio 2:1, under continuous stirring and nitrogen atmosphere protection, heat up to 90 ° C for 2 hours to obtain -NCO-terminated polyurethane prepolymer;

[0022] (3) In another reactor, add polypropylene glycol with a molecular weight of 2000, 3.0 wt% of diisocyanate containing organosilicon side chains prepared in step (1) and isophorone diisocyanate to control the -NCO / -OH molar ratio 1:2, under continuous stirring and nitrogen atmosphere protection, heat up to 90°C for 2 hours to form -OH-terminated polyurethane prepolymer;...

Embodiment 2

[0025] (1) Put 1 mole of HDI trimer and 1 mole-average molecular weight of 2000 and viscosity of 4000cps monohydroxyl silicone oil into the reactor, and react at 70-80°C for 2 hours to obtain diisocyanate containing silicone side chains;

[0026] (2) Polycarbonate diol, 4,4'-dicyclohexylmethane diisocyanate H with a number average molecular weight of 10000 12 Add MDI, hydrophilic chain extender dimethylolpropionic acid (solid weight) 4.5wt% to the reaction vessel, control the -NCO / -OH molar ratio of 2:1, and raise the temperature to 80-90°C under continuous stirring and nitrogen atmosphere protection. ℃ for 2 hours to form -NCO-terminated polyurethane prepolymer;

[0027] (3) In another reactor, add polytetrahydrofuran diol with a number average molecular weight of 2000, 5.0 wt% of diisocyanate containing organosilicon side chains prepared in step (1) and toluene diisocyanate to control -NCO / -OH The molar ratio is 1:2, under the protection of continuous stirring and nitrogen ...

Embodiment 3

[0030] (1) Put 1 mole of HDI trimer and 1 mole-average molecular weight of 1000 and viscosity of 3000cps monohydroxyl silicone oil into the reactor, and react at 70-80°C for 2 hours to obtain diisocyanate containing silicone side chains;

[0031] (2) Polycaprolactone diol with a number average molecular weight of 4000, hexamethylene diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, hydrophilic chain extender dimethylol propionic acid (solid weight) Add 5.0 wt% into the reaction vessel, control the molar ratio of -NCO / -OH to 2:1, and raise the temperature to 80-90°C for 2.5 hours under the protection of continuous stirring and nitrogen atmosphere to form -NCO-terminated polyurethane prepolymer;

[0032] (3) In another reactor, add 100 parts of dihydroxy polybutadiene diol with a number average molecular weight of 10,000, 4.0 wt% of diisocyanate containing organosilicon side chains prepared in step (1) and hexamethylene diisocyanate , control the -NCO / -OH molar ratio of 1:2, un...

PUM

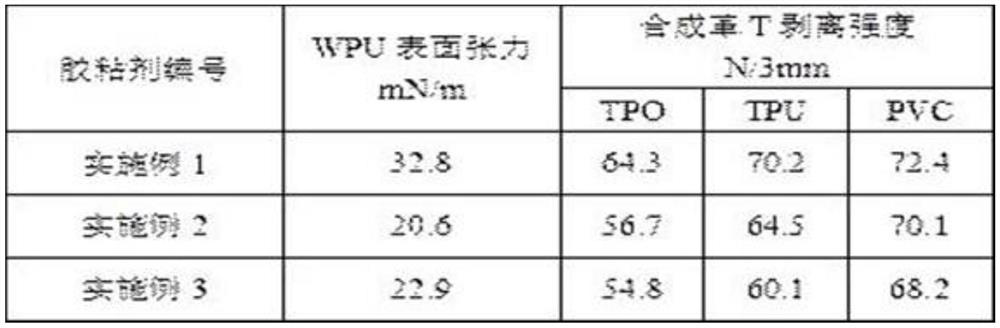

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com