High-adaptability mud-resistant water reducing agent and preparation method thereof

An adaptable, water-reducing agent technology, applied in the field of highly adaptable anti-mud type water-reducing agents, can solve problems such as poor adaptability, and achieve the effects of ensuring durability, increasing rigidity, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A method for preparing a highly adaptable mud-resistant water reducer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and each raw material component includes:

[0036] 16.8 parts of 2-(allyloxy)phenol

[0037] Ethylene oxide 61.0 parts

[0038] Propylene oxide 242.1 parts

[0039] 0.8 parts of boron trifluoride and lithium aluminum tetrahydride with a mass ratio of 1:2.3

[0040] Acrylic acid 33.0 parts

[0041] 5.6 parts of ascorbic acid and sodium formaldehyde sulfoxylate with a mass ratio of 1:1.2

[0042] The mass ratio is 2:1 ammonium persulfate and azobisisobutyronitrile 6.7 parts

[0043] 3.2 parts of thioglycolic acid and mercaptoethanol with a mass ratio of 2:1.3

[0044] 7.3 parts of sodium bicarbonate and triisopropanolamine with a mass ratio of 1.3:1

[0045] The remainder is water, and the total mass is 1000 parts.

[0046] The preparation method is as follows:

[0047] (1) Add 16.80 parts of...

Embodiment 2-6

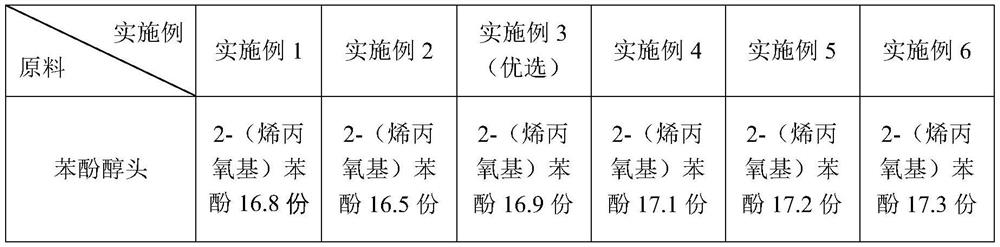

[0051] Concrete parameter (step is identical) in concrete raw material and preparation method is different with embodiment 1, specifically as shown in following table 1 and table 2 (table 1 is raw material, and table 2 is the parameter in preparation method), in table 2 Not listed expression is identical with embodiment 1:

[0052] The parts are all parts by mass.

[0053] Table 1

[0054]

[0055]

[0056]

[0057] Table 2

[0058]

[0059] The product of the present invention and Hubei Tengchen TC-900J water reducing agent were prepared into C50 concrete samples, and Tables 3 and 4 were obtained through testing.

[0060] table 3

[0061]

[0062] Table 4

[0063]

[0064] It can be seen from Table 4 that the highly adaptable anti-mud type superplasticizer solution synthesized by the method of the present invention shows better slump, water reducing rate and bleeding rate in the concrete system.

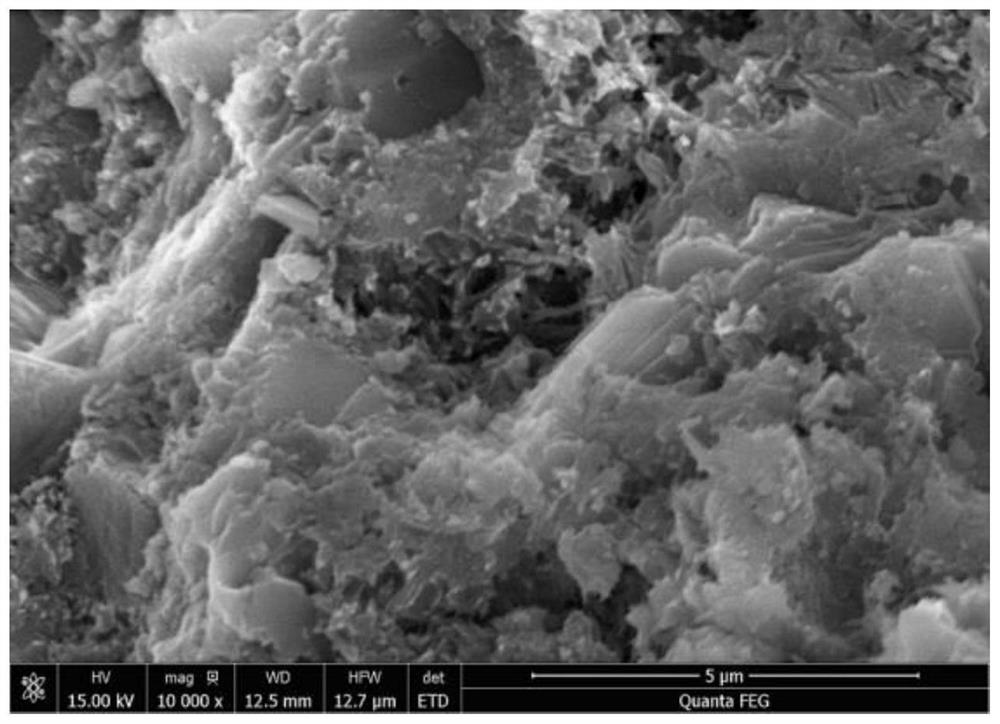

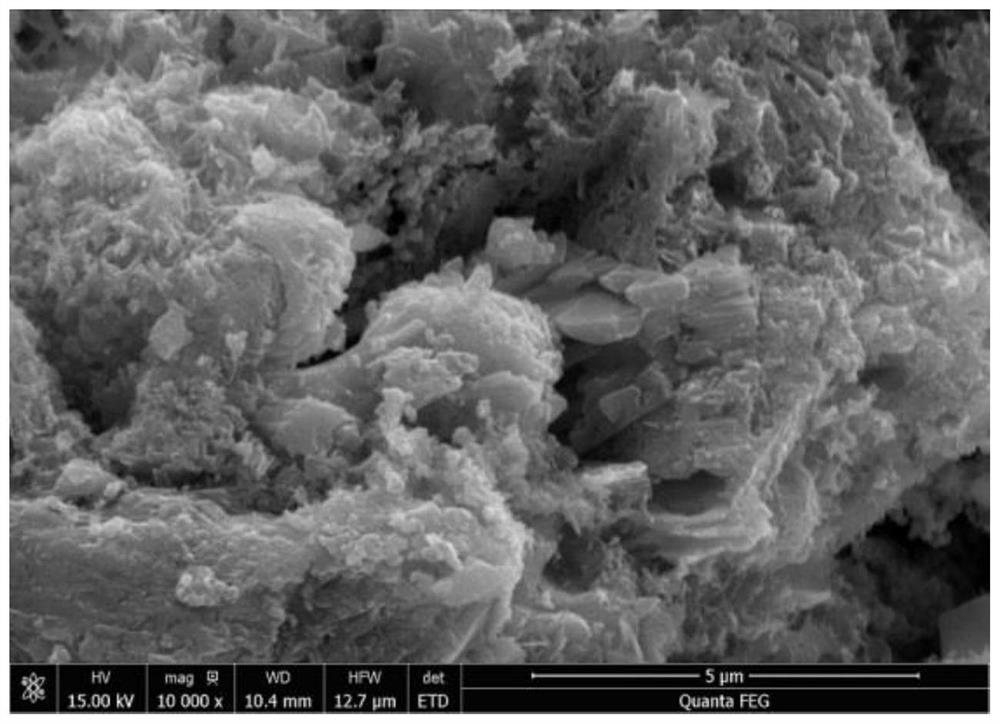

[0065] figure 1 , figure 2 SEM images of TC-900J wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com