Low-temperature-sintered temperature-stable composite microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and temperature stability, which is applied in the field of ceramic materials for microwave electronic components and electronic components. The effect of high factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

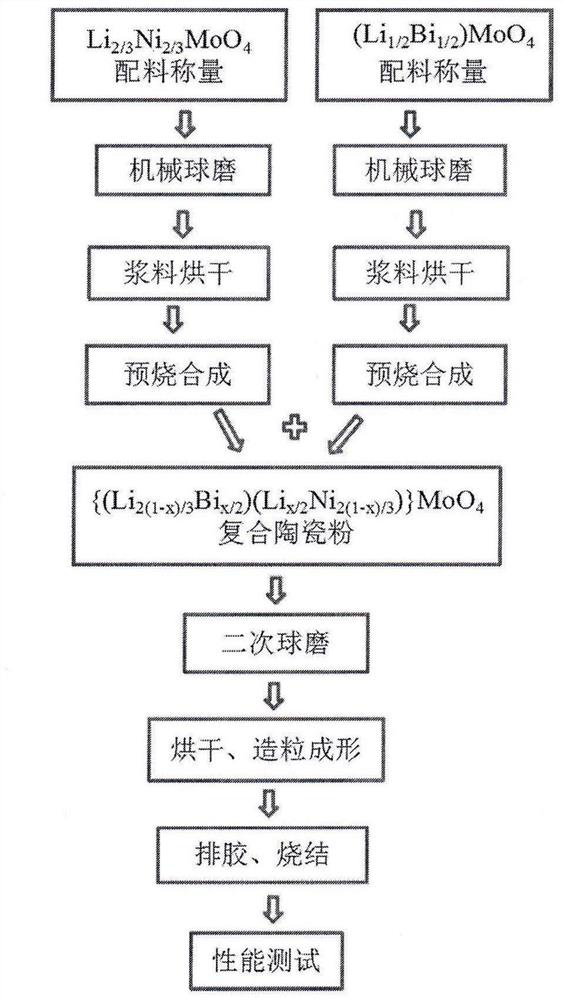

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: x=0.2

[0031] Preparation:

[0032] 1) Li with a purity ≥ 99.9% 2 CO 3 , NiO, Bi 2 o 3 and MoO 3 as raw material, according to Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 )MoO 4 Stoichiometric ratio preparation and weighing, using absolute ethanol and agate balls as the ball milling medium, ball milling at a speed of 300r / min for 4-6 hours, drying at 80°C, and then heating at a rate of 2°C / min-5°C / min Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 )MoO 4 ceramic powder.

[0033] 2) The ceramic powder synthesized by step 1) pre-fired in proportion to (1-x)Li 2 / 3 Ni 2 / 3 MoO 4 -x(Li 1 / 2 Bi 1 / 2 ) MoO 4 The ingredients get {(Li 1.6 / 3 Bi 0.2 / 2 )(Li 0.2 / 2 Ni 1.6 / 3 )}MoO 4 Composite ceramic powder; use absolute ethanol and agate balls as the ball milling medium to mill the prepared composite ceramic powder in a high-speed ball mill with a speed of 250r / min to 350r / min for 8h to 12h and mix evenly; bake at 80°C Dry, grind into powder and sieve, add p...

Embodiment 2

[0037] Embodiment 2: x=0.3

[0038] Preparation:

[0039] 1) Li with a purity ≥ 99.9% 2 CO 3 , NiO, Bi 2 o 3 and MoO 3 as raw material, according to Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 ) MoO 4 Stoichiometric ratio preparation and weighing, using absolute ethanol and agate balls as the ball milling medium, ball milling at a speed of 300r / min for 4h~6h after mixing, drying at 80°C, and then heating at a rate of 2°C / min~5°C / min Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 ) MoO 4 ceramic powder.

[0040] 2) The ceramic powder synthesized by step 1) pre-fired in proportion to (1-x) Li 2 / 3 Ni 2 / 3 MoO 4 -x(Li 1 / 2 Bi 1 / 2 ) MoO 4 The ingredients get {(Li 1.4 / 3 Bi 0.3 / 2 )(Li 0.3 / 2 Ni 1.4 / 3 )}MoO 4 Composite ceramic powder; use absolute ethanol and agate balls as the ball milling medium to mill the prepared composite ceramic powder in a high-speed ball mill with a speed of 250r / min to 350r / min for 8h to 12h and mix evenly; at a temperature of 80°C Drying, grindin...

Embodiment 3

[0044] Embodiment 3: x=0.4

[0045] Preparation:

[0046] 1) Li with a purity ≥ 99.9% 2 CO 3 , NiO, Bi 2 o 3 and MoO 3 For raw materials, press Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 ) MoO 4 The stoichiometric ratio of the chemical formula is prepared and weighed, with anhydrous ethanol and agate balls as the ball milling medium, ball milled at a speed of 300r / min for 4h to 6h, then dried at 80°C, and then dried at 2°C / min to 5°C / min The heating rate is kept at 500°C-600°C for 2-4 hours to obtain Li 2 / 3 Ni 2 / 3 MoO 4 , (Li 1 / 2 Bi 1 / 2 ) MoO 4 ceramic powder.

[0047] 2) The ceramic powder synthesized by step 1) pre-fired in proportion to (1-x)Li 2 / 3 Ni 2 / 3 MoO 4 -x(Li 1 / 2 Bi 1 / 2 ) MoO 4 Mixing ingredients to obtain composite ceramic powder; use absolute ethanol and agate balls as the ball milling medium for the prepared composite ceramic powder, and ball mill it in a high-speed ball mill with a speed of 250r / min to 350r / min for 8 to 12 hours to mix evenly;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com