Blowdown treatment process for thermodynamic system of hot water boiler

A hot water boiler and thermal system technology, applied in the direction of heating water/sewage treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of poor purification efficiency, cumbersome sewage treatment process, large sewage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

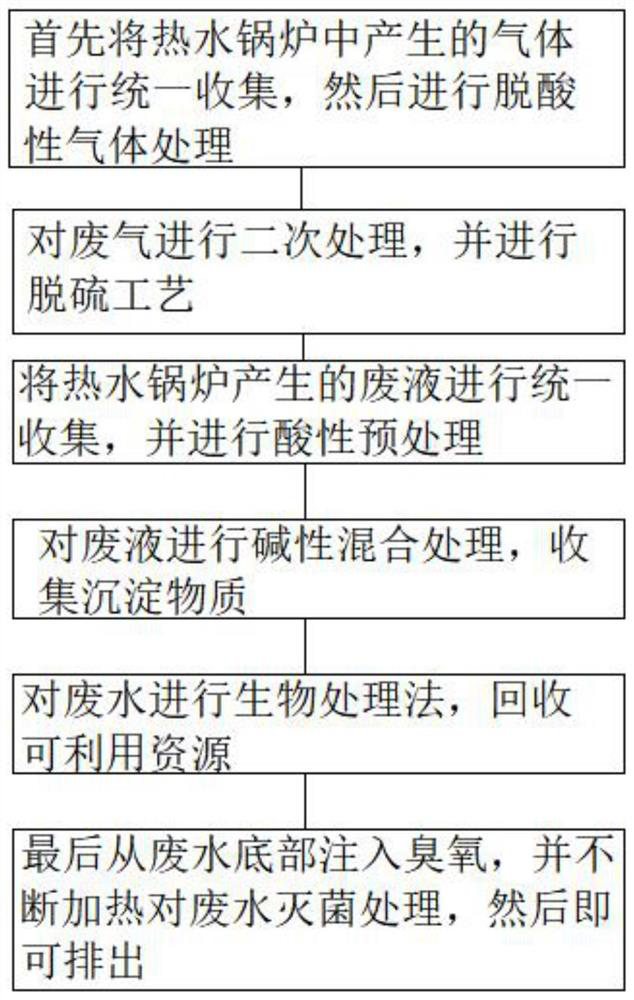

Method used

Image

Examples

Embodiment 1

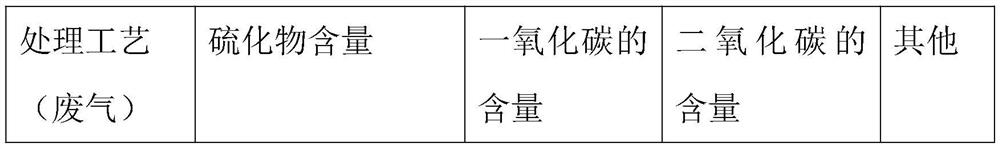

[0039] First, the acid waste gas collects the waste gas generated by the hot water boiler system through each branch pipe, enters the main air pipe, and uses the acid waste gas to collect the waste gas generated by each equipment and area through the branch pipes through the waste gas treatment scrubber, enters the main air pipe, and passes through the waste gas The treatment scrubber uses the contact between gas and liquid to transfer the pollutants in the gas to the liquid, and then separates and purifies the clean gas from the polluted liquid, and finally is sucked by the anti-corrosion fan to the activated carbon adsorption bed to absorb harmful pollutants in the waste gas. Composition, gas detection PH is controlled at 6.8, that is, the emission standard is met, and the waste gas is treated with water to reduce dust and delay. The treated flue gas enters the cooling tower after the coarse filtration of the dust collector, and sprays it in the cooling tower Cooling water, c...

Embodiment 2

[0041] First, the acid waste gas collects the waste gas generated by the hot water boiler system through each branch pipe, enters the main air pipe, and uses the acid waste gas to collect the waste gas generated by each equipment and area through the branch pipes through the waste gas treatment scrubber, enters the main air pipe, and passes through the waste gas The treatment scrubber uses the contact between gas and liquid to transfer the pollutants in the gas to the liquid, and then separates and purifies the clean gas from the polluted liquid, and finally is sucked by the anti-corrosion fan to the activated carbon adsorption bed to absorb harmful pollutants in the waste gas. Composition, gas detection PH is controlled at 6.8, and the waste gas is sprayed with water to reduce dust and delay. The treated flue gas enters the cooling tower after the coarse filtration of the dust collector, and sprays cooling water in the cooling tower to dissipate the flue gas. The gas is cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com