A kind of method for treating fluorine-containing waste electrolyte

A waste electrolyte and content technology, applied in chemical instruments and methods, aluminum fluoride, alkali metal sulfite/sulfite, etc., can solve the problems of low raw material utilization rate, low effective aluminum fluoride content, high processing temperature, etc. , to improve the purity and recovery of fluorine, promote the reaction, and reduce the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

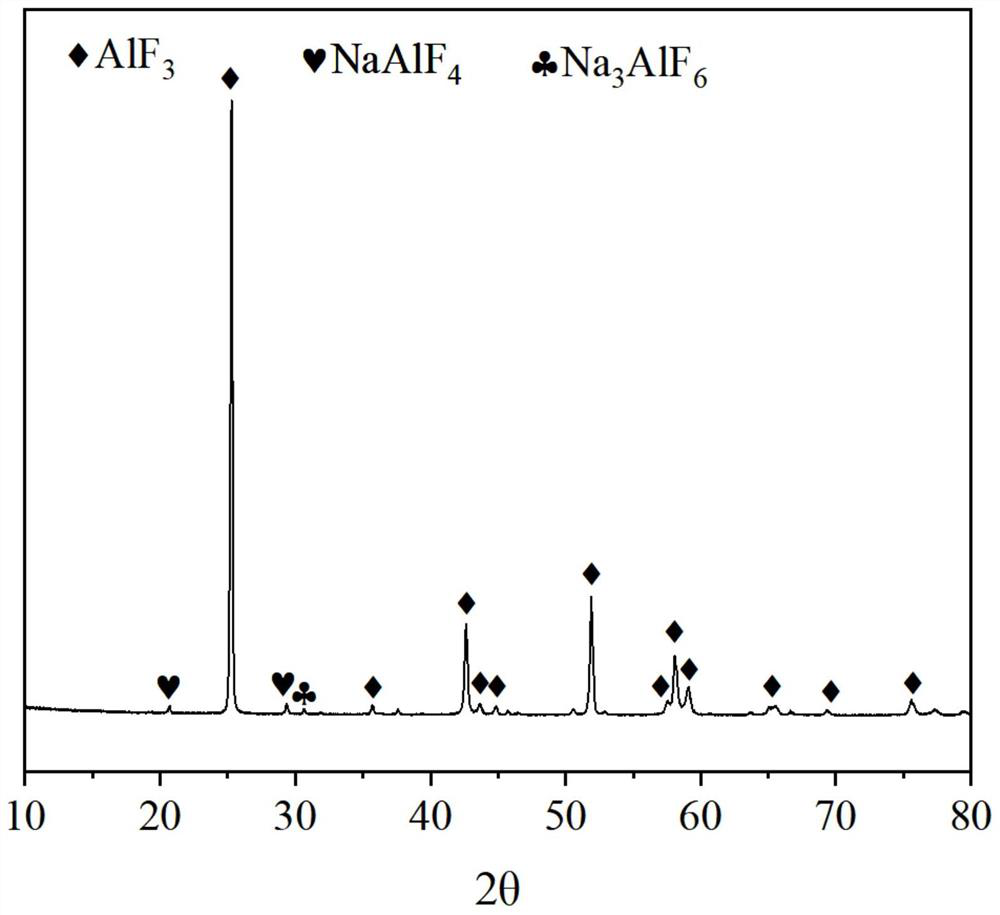

Embodiment 1

[0038] The steps of the method for treating the fluorine-containing waste electrolyte of the present embodiment are as follows:

[0039] (1) Take 50kg of waste electrolyte from an electrolytic aluminum plant (XRF fluorescence analysis: F 49.68wt.%, Na 21.48wt.%, Al14.48%, Ca 5.46, K 5.13wt.%, O 2.59wt.%, Mg 0.57 wt.%, S 0.18wt.%), crushed to less than 2mm to obtain waste electrolyte powder for use;

[0040] (2) Take 100kg of aluminum sulfate octadecahydrate and heat it up to 300°C at a rate of 10°C / min, keep the temperature for 2 hours, then heat up to 400°C, keep the temperature for 2 hours, and crush it to less than 2 mm after cooling, and weigh to obtain anhydrous aluminum sulfate powder 51.5 kg for use;

[0041] (3) Take 48kg of waste electrolyte powder, 43kg of anhydrous aluminum sulfate powder and 1.5kg of sodium carbonate and mix them evenly, and then ball mill to pass through a 100-mesh sieve to obtain mixed powder.

[0042] (4) Put the mixed powder obtained in step ...

Embodiment 2

[0047] Take 50kg of the same waste electrolyte as in Example 1, change the temperature in step (4) to 600 ° C, and other conditions remain unchanged, repeat the steps (1)-(6) of Example 1, and finally obtain 38.6kg of aluminum fluoride product, Got by-product potassium sulfate 10.8kg, by-product sodium sulfate 40.5kg. The obtained aluminum fluoride was detected, and the results are shown in Table 1.

Embodiment 3

[0049] Example 1 was repeated, and the difference was only that: the temperature in step (4) was controlled to 580° C., and the obtained aluminum fluoride product was detected. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com