Novel precision correcting mechanism of punching machine

A new type of high-precision technology, applied in the field of precision deep drawing stamping, can solve the problems of large gap and inability to meet the requirements of high-precision drawing stamping, etc., to achieve increased friction, enhanced precision correction ability, and increased contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

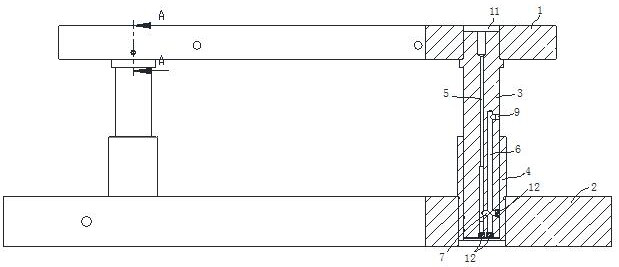

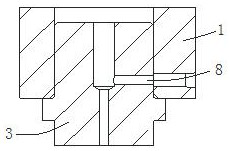

[0019] Such as Figure 1 to Figure 3 As shown, a new type of precision correction mechanism for a punch press includes an upper template 1, a lower template 2, a guide post 3 installed between the upper template 1 and the lower template 2, a guide sleeve 4 set on the guide post 3, and a guide post 3 is provided with a cooling oil first flow guide channel 5 and a cooling oil second flow guide channel 6, the first cooling oil flow guide channel 5 and the cooling oil second flow guide channel 6 are connected through the connecting hole 7, the guide post 3 A cooling oil inlet 8 and a cooling oil outlet 9 connected to the first flow guiding channel 6 or the second cooling oil guiding channel 7 are provided on the top.

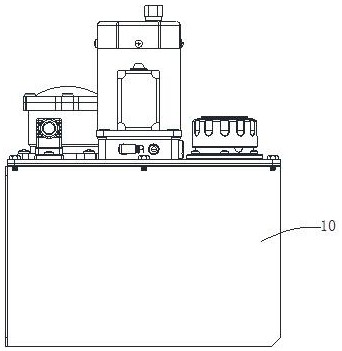

[0020] Further, a cooling oil machine 10 is connected between the cooling oil inlet 8 and the cooling oil outlet 9 . Plugs are installed at the ends of the first cooling oil diversion channel 5, the second cooling oil diversion channel 6 and the connecting hole 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com