MIL-101/PDVB composite material for adsorbing benzene gas as well as preparation method and application of MIL-101/PDVB composite material

A composite material and gas technology, applied in the field of MIL-101/PDVB composite material and its preparation, can solve the problems of small surface area, confinement, hydroxyl attack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. At room temperature, mix 2ml of deionized water, 20ml of tetrahydrofuran, 1.6g of divinylbenzene, 0.4g of methacrylic acid, and 0.05g of azobisisobutyronitrile and stir for 4-8h, then pour into polytetrafluoroethylene water In a thermal reaction kettle, keep warm at 100°C for 24h, cool with the furnace until the solvent is volatilized, and then place it in a vacuum drying oven at 60°C for 12h and grind to obtain carboxyl-modified PDVB (hereinafter referred to as A), the structural formula is as follows:

[0030]

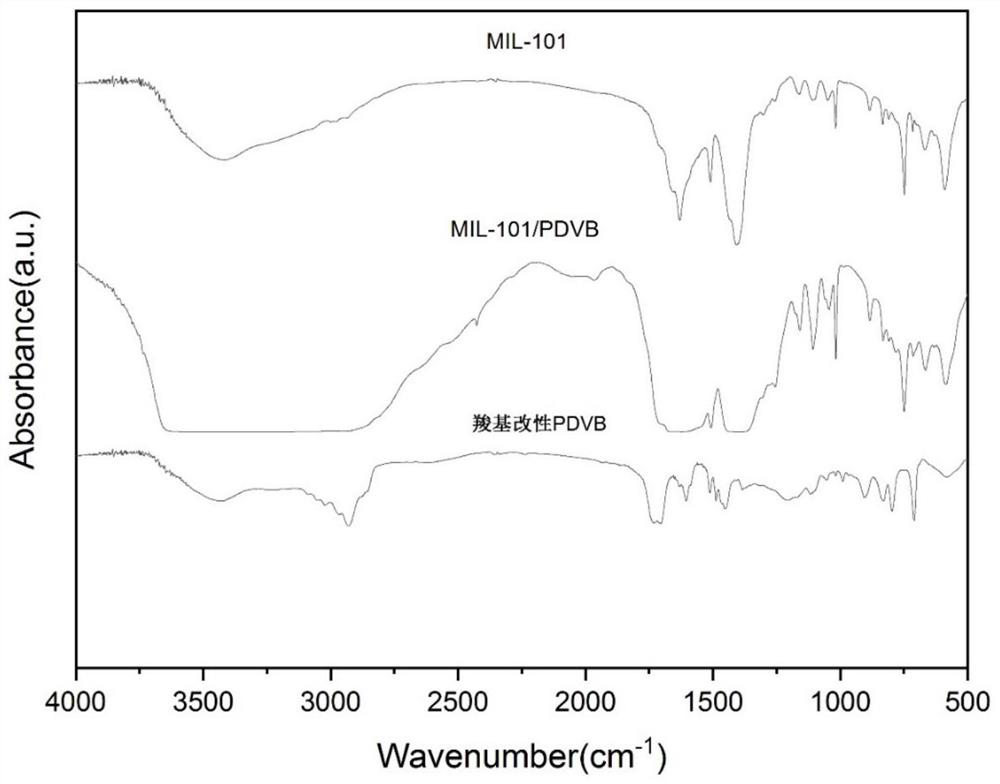

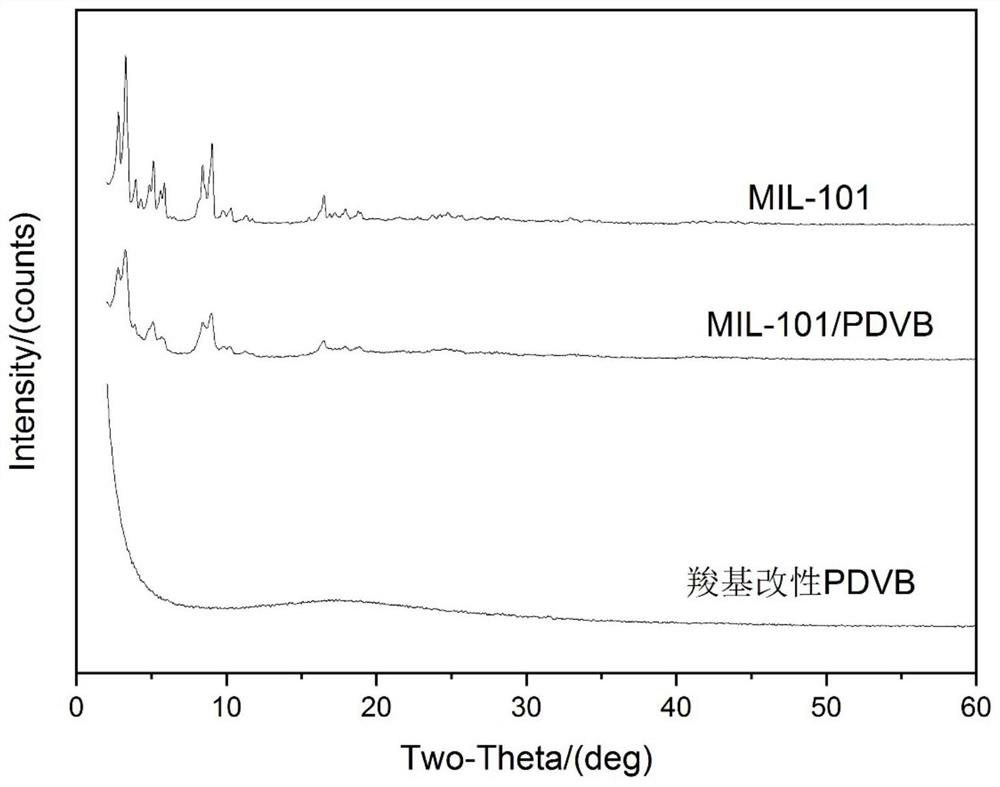

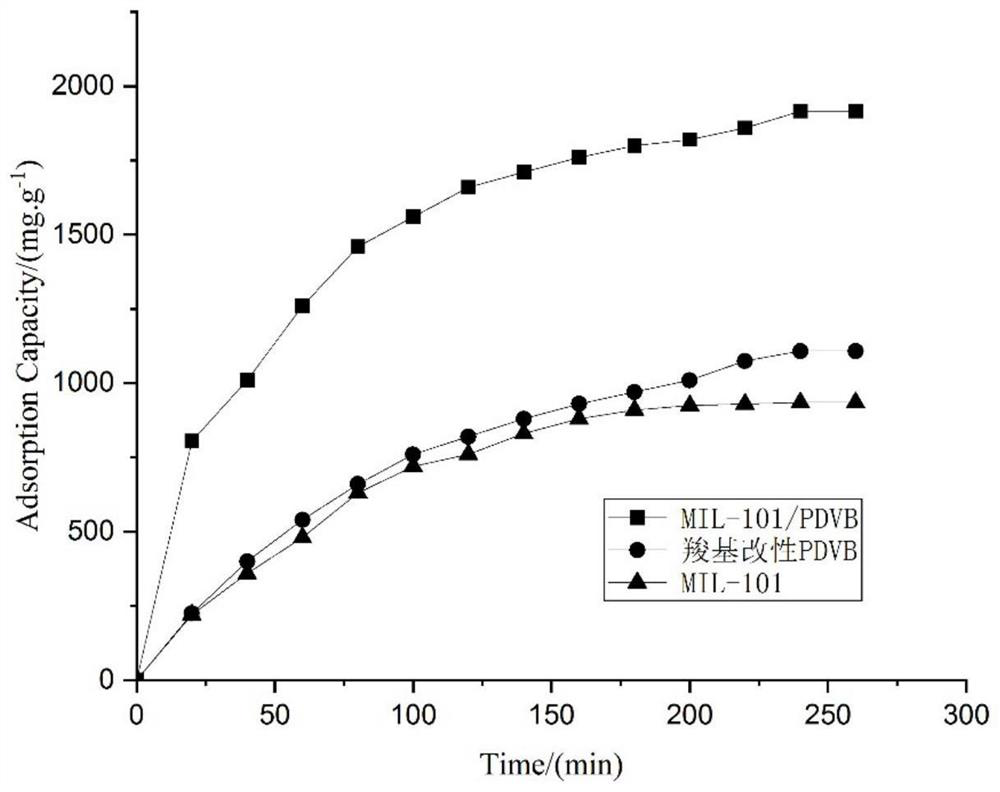

[0031] Polydivinylbenzene (PDVB) is an adsorption resin with high specific surface area, large pore volume, controllable pore size, good chemical stability and other characteristics, so it is used as a gas adsorbent; and PDVB brings The benzene ring structure makes the composite material have excellent hydrophobic properties, which improves the competitive adsorption capacity of PDVB for benzene gas. In the present invention, combined with the unique por...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, the difference is: "0.149gA (the proportion of carboxyl-modified PDVB in the MIL-101 / PDVB composite material used to adsorb benzene gases is 5%), 2g Nine Chromium nitrate water, 0.2g sodium hydroxide, 0.83g terephthalic acid, 25ml ionized water, mix and sonicate, as follows:

[0039] a. This step is identical with the step of embodiment one;

[0040] b. 0.149gA (the proportion of carboxy-modified PDVB in the MIL-101 / PDVB composite material used to adsorb benzene gases is 5%), 2g chromium nitrate nonahydrate, 0.2g sodium hydroxide, 0.83g p-benzene Diformic acid, 25ml ionic water, mix and sonicate to obtain precursor solution B, namely MIL-101 / PDVB precursor solution;

[0041] c. This step is the same as the step in Embodiment 1;

[0042] d. This step is the same as the step in Embodiment 1;

[0043] e. this step is identical with the step of embodiment one;

[0044] The MIL-101 / PDVB composite material used for th...

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, the difference is: "0.181gA (the proportion of carboxyl-modified PDVB in the MIL-101 / PDVB composite material used to adsorb benzene gases is 6%), 2g Nine Water Chromium Nitrate, 0.2g Sodium Hydroxide, 0.83g Terephthalic Acid, 25ml Ionized Water, mixed and sonicated", as follows:

[0047] a. This step is identical with the step of embodiment one;

[0048] b. 0.181gA (the proportion of carboxy-modified PDVB in MIL-101 / PDVB used to adsorb benzene gases is 6%), 2g chromium nitrate nonahydrate, 0.2g sodium hydroxide, 0.83g terephthalic acid , 25ml of ionized water, mixed and sonicated to obtain precursor solution B, namely MIL-101 / PDVB precursor solution;

[0049] c. This step is the same as the step in Embodiment 1;

[0050] d. This step is the same as the step in Embodiment 1;

[0051] e. this step is identical with the step of embodiment one;

[0052] The MIL-101 / PDVB composite material used for the adsorption of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com