Modified polyamide composite nanofiltration membrane and preparation method thereof

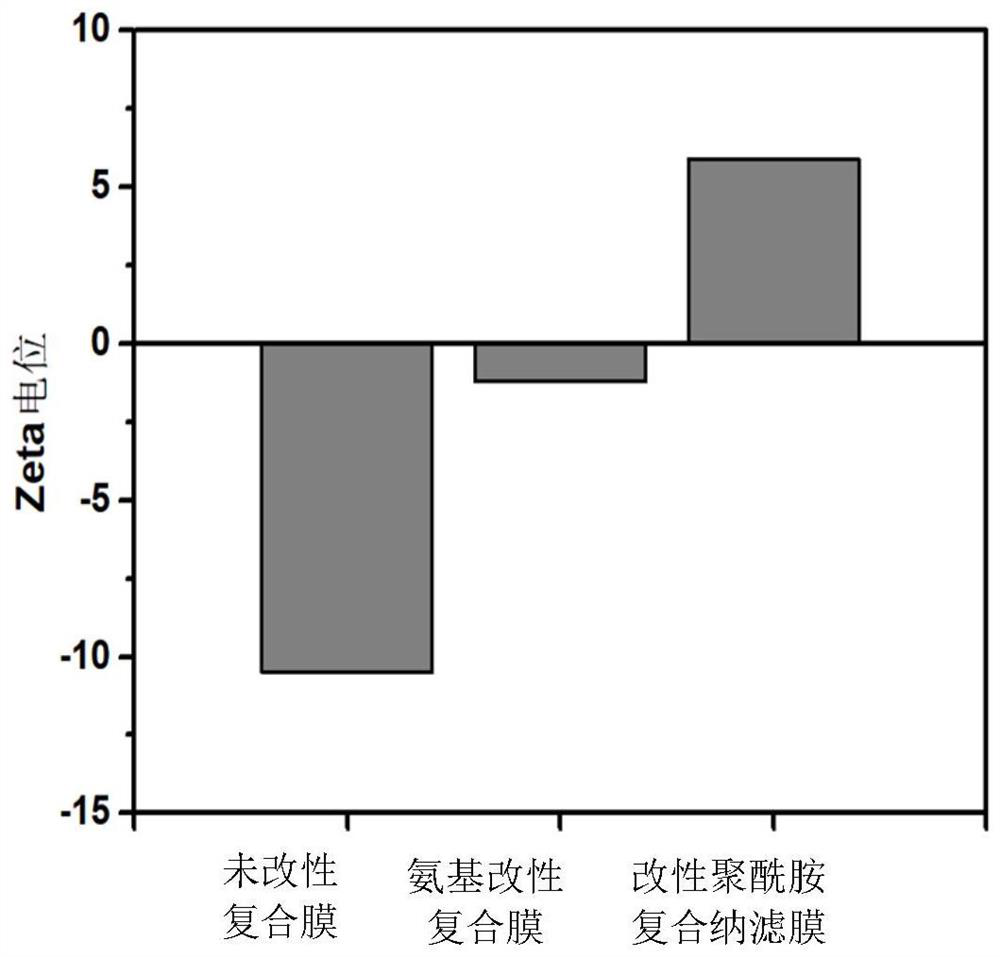

A composite nanofiltration membrane and polyamide technology, applied in the field of membrane separation, can solve the problems of poor positive charge, poor rejection rate of high-valence cations, etc., and achieve good separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

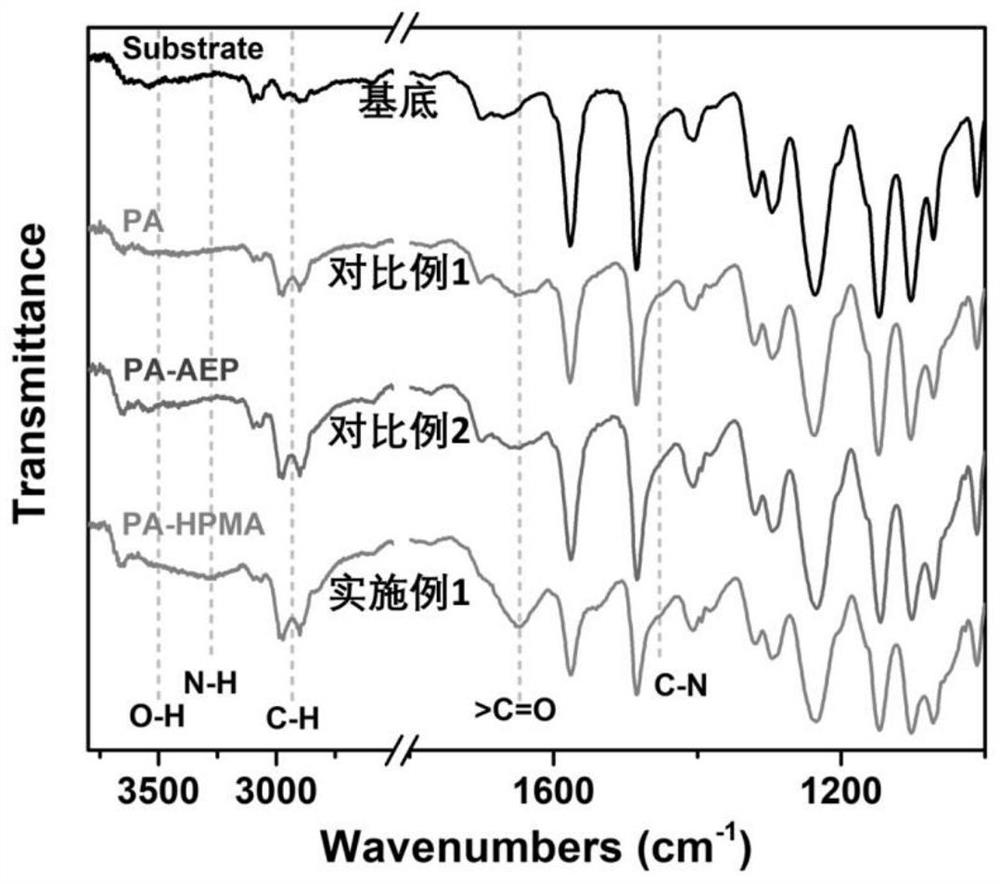

[0029] The preparation method of the modified polyamide composite nanofiltration membrane provided by the present invention comprises the following steps: (1) using polyamines and polyacyl chlorides as polymerization raw materials, in-situ polymerization on the surface of the supporting base membrane by interfacial polymerization to form a polyamide layer , to obtain an unmodified composite membrane; (2) use a diamine monomer to aminate the unmodified composite membrane to obtain an amino-modified composite membrane; (3) use diamine monomer and diene monomer as polymerization raw materials , in-situ polymerization on the polymer layer of the amino-modified composite membrane to generate a hyperbranched polymer to obtain a modified polyamide composite nanofiltration membrane.

[0030] In some embodiments, the process of step (1) includes: immersing the supporting base film in an aqueous phase solution containing polyamines, taking it out, then immersing it in an oil phase soluti...

Embodiment 1

[0040] The preparation method of modified polyamide composite nanofiltration membrane is as follows:

[0041] (1) N-aminoethylpiperazine is dissolved in water to obtain N-aminoethylpiperazine solution; trimesoyl chloride is dissolved in n-hexane to obtain the n-hexane solution of trimesoyl chloride, wherein N -The mass fraction of aminoethylpiperazine is 0.5%, and the massfraction of trimesoyl chloride is 0.1%; the support base membrane (pore diameter is 20nm) that will comprise polyethersulfone layer is soaked in the water of N-aminoethylpiperazine After taking it out, immerse it in the n-hexane solution of trimesoyl chloride for 1 minute. After taking it out, dry it at 80°C for 8 minutes to obtain an unmodified composite film;

[0042] (2) N-aminoethylpiperazine is dissolved in water to make N-aminoethylpiperazine solution, wherein the mass fraction of N-aminoethylpiperazine is 1%; The composite membrane was immersed in the N-aminoethylpiperazine solution for 2 hours, and a...

Embodiment 2

[0045] The mass fraction of the N-aminoethylpiperazine of step (3) in Example 1 is increased to 12.4%, making N-aminoethylpiperazine and N, the N-methylenebisacrylamide mol ratio is 1.2: 1. Other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com