Battery case and battery pack

A technology for battery packs and casings, applied in the field of battery pack casings and battery packs, can solve the problems of high cost, corrosion, inability to prevent external water vapor from entering the battery pack, etc., and achieve the effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

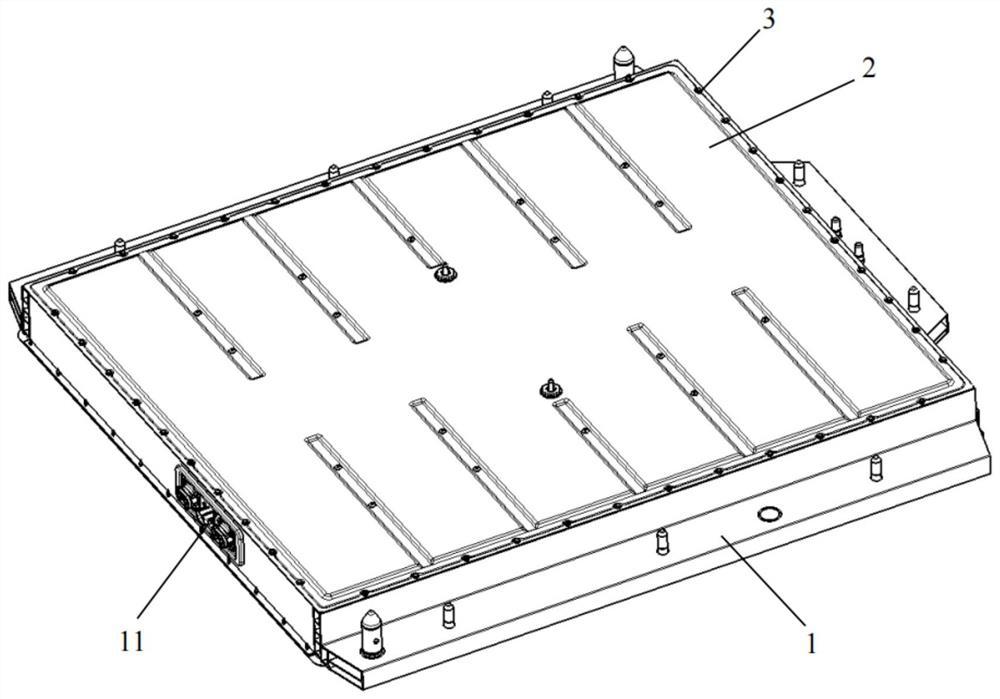

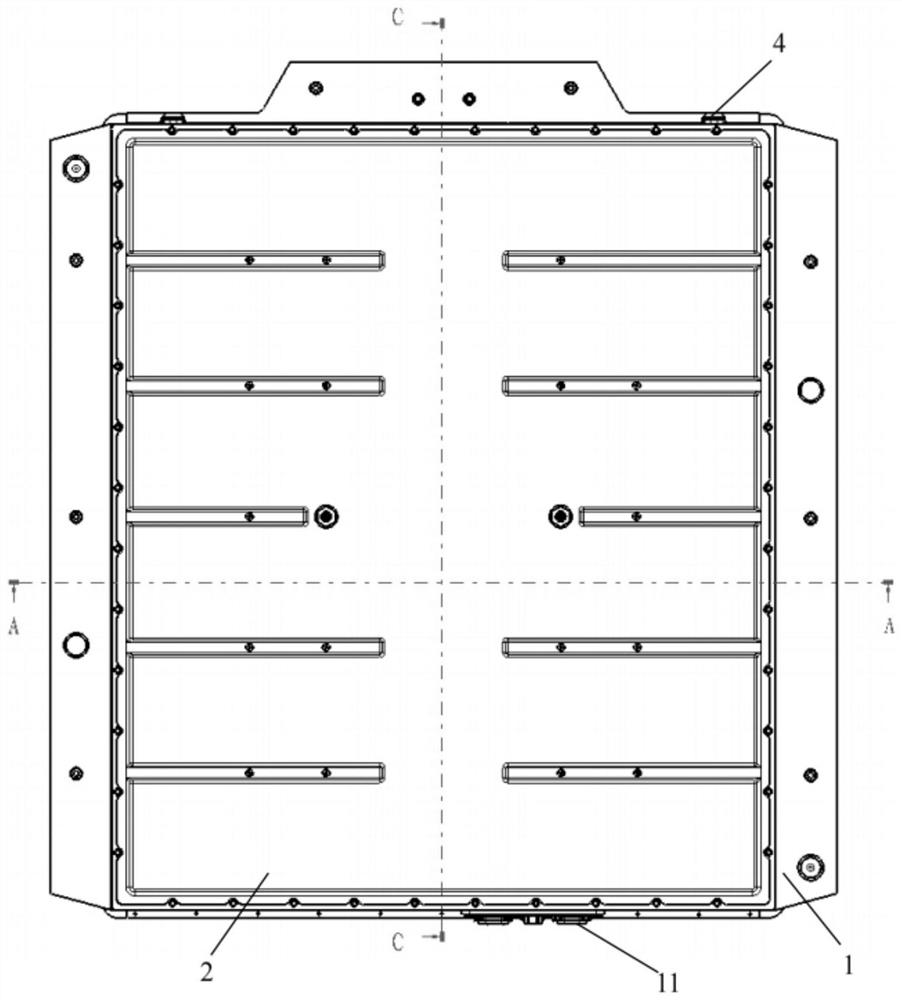

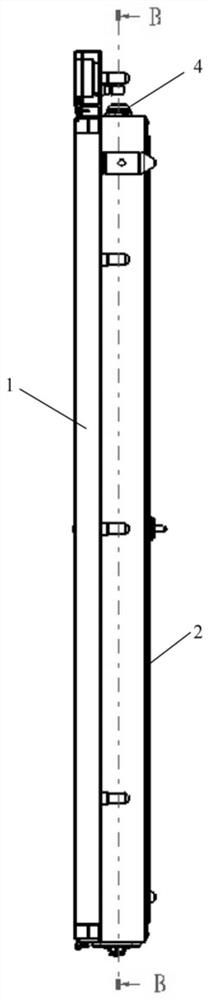

[0037] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 The structure of the battery pack casing of the embodiment of the present application is shown; the battery pack casing is composed of a battery tray 1, an upper cover 2, a connecting piece 3, an explosion-proof vent valve 4 and a sealing member 5; the above-mentioned battery pack casing is designed to be only capable of The gas is exchanged with the outside through the explosion-proof vent valve 4 . The explosion-proof ventilation valve 4 is designed to meet the functions of waterproof and ventilation. When the internal pressure of the battery pack casing exceeds the set value, the explosion-proof ventilation valve 4 will open the pressure relief channel. The battery tray 1 is composed of a front frame 16 , a rear frame 17 , a left frame 15 , a right frame 12 , a longitudinal beam 14 , a plurality of cross beams 13 , a bottom plate structure 19 , an electrical panel 11 , an isolation...

Embodiment 2

[0047] Figure 14 , Figure 15 Another embodiment of the isolation assembly is shown, and the other structure is the same as that of Embodiment 1.

[0048] The isolation assembly 18 is preferably an isolation sleeve made of elastic material or a folding telescopic bag made of polymer material. One end of the isolation assembly 18 is connected to the longitudinal beam 14 and realizes the connection between the front space 143 and the rear space 144 inside the longitudinal beam 14 cavity. Isolation, specifically, the isolation assembly 18 and the stringer 14 can be connected and sealed by bonding, heat fusion, crimping, or the like. When the internal air pressure of the battery pack is greater than the external air pressure, the force exerted by the internal air pressure of the battery pack on the isolation component 18 will be greater than the force exerted on the isolation component 18 by the external air pressure, and the resultant force applied inside the isolation componen...

Embodiment 3

[0050] A battery pack is provided, including a battery module and the battery pack case described in the above solution, preferably, the interstitial space in the battery pack is filled with argon gas, nitrogen gas or carbon dioxide gas. It can be understood that the battery pack automatically balances the internal and external pressure difference by discharging or inhaling the external air through the explosion-proof vent valve 4. During this process, the external air does not enter the area where the battery module is accommodated; therefore, the humidity of the external air will not affect the interior of the battery pack. Due to the humidity of the filling gas, the dry gas inside the battery pack will not condense, thereby reducing the risk of corrosion and short circuits caused by condensation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com