Anti-overcharge low-temperature electrolyte and lithium ion battery based on same

An anti-overcharge and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of inability to discharge, overcharge and discharge, low discharge capacity, etc., and achieve the effect of reducing impedance, low viscosity, and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the above-mentioned electrolyte, the method comprising: mixing an organic solvent, a lithium salt, and the above-mentioned additives to prepare the electrolyte, and the mixing is not limited by the order of addition.

[0039]The present invention also provides a lithium ion battery, which includes the above-mentioned electrolyte solution. The lithium ion battery includes a positive electrode sheet, a separator and a negative electrode sheet, and the separator is arranged between the positive electrode sheet and the negative electrode sheet.

[0040] Specifically, in a specific embodiment of the present invention, the positive electrode sheet includes one or two positive electrode active material layers and a positive electrode current collector. Wherein the positive electrode active material layer includes a positive electrode active material, a conductive agent and a positive electrode binder, the positive elec...

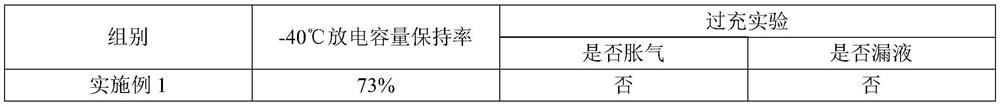

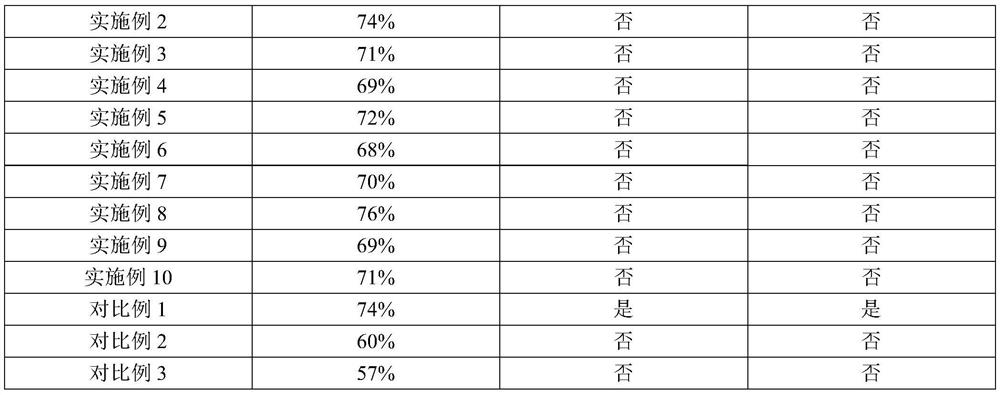

Embodiment 1

[0045] Mix the solvent ethyl acetate, ethylene carbonate, propylene carbonate, diethyl carbonate, and vinyl methyl carbonate, and add vinylene carbonate, 1,3-propane sultone, vinyl sulfite, 1,4-di-tert-butyl-2,5-dimethoxybenzene was used as an additive, and finally lithium hexafluorophosphate and lithium tetrafluoroborate were added to obtain the anti-overcharge low-temperature electrolyte of Example 1.

[0046] In the obtained anti-overcharge low-temperature electrolyte, according to mass percentage, the above-mentioned components are respectively: 36wt% of ethyl acetate, 12wt% of ethylene carbonate, 13wt% of propylene carbonate, 15wt% of diethyl carbonate, methylethylene carbonate 2wt% ester as organic solvent (78wt%), lithium hexafluorophosphate 14wt% and lithium tetrafluoroborate 3wt% as lithium salt (17wt%), vinylene carbonate 1.5wt%, 1,3-propane sultone 1.2wt% and vinyl sulfite 0.3wt% as a low-resistance film-forming additive (3wt%), and 2wt% of 1,4-di-tert-butyl-2,5 dim...

Embodiment 2

[0049] Mix the solvent ethyl acetate, ethylene carbonate, propylene carbonate, diethyl carbonate, and vinyl methyl carbonate, and add vinylene carbonate, 1,3-propane sultone, vinyl sulfite, 1,4-di-tert-butyl-2,5-dimethoxybenzene was used as an additive, and finally lithium hexafluorophosphate and lithium tetrafluoroborate were added to obtain the anti-overcharge low-temperature electrolyte of Example 1.

[0050] In the obtained anti-overcharge low-temperature electrolyte, according to mass percentage, the above-mentioned components are respectively: 36wt% of ethyl acetate, 12wt% of ethylene carbonate, 13wt% of propylene carbonate, 15wt% of diethyl carbonate, methylethylene carbonate 2wt% of ester as organic solvent (78wt%), 14wt% of lithium hexafluorophosphate and 3wt% of lithium tetrafluoroborate as lithium salt (17wt%), 2wt% of vinylene carbonate, 1.7wt% of 1,3-propane sultone and Vinyl sulfite 0.3wt% is used as a low-resistance film-forming additive (3wt%), and 1,4-di-tert-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com