Carbon-coated PtPdIr/C oxygen reduction electrocatalyst as well as preparation method and application thereof

An electrocatalyst and carbon-coated technology, which is applied in the fields of energy materials and electrochemistry, can solve problems affecting service life, shedding, agglomeration, etc., and achieve improved heating efficiency, prevention of shedding and agglomeration, high oxygen reduction catalytic activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

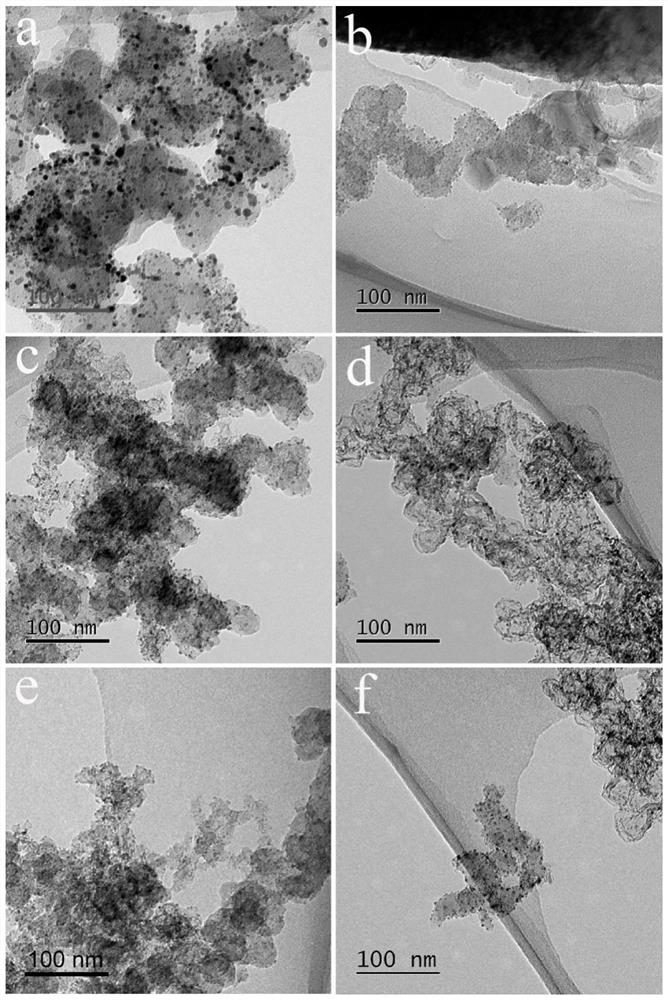

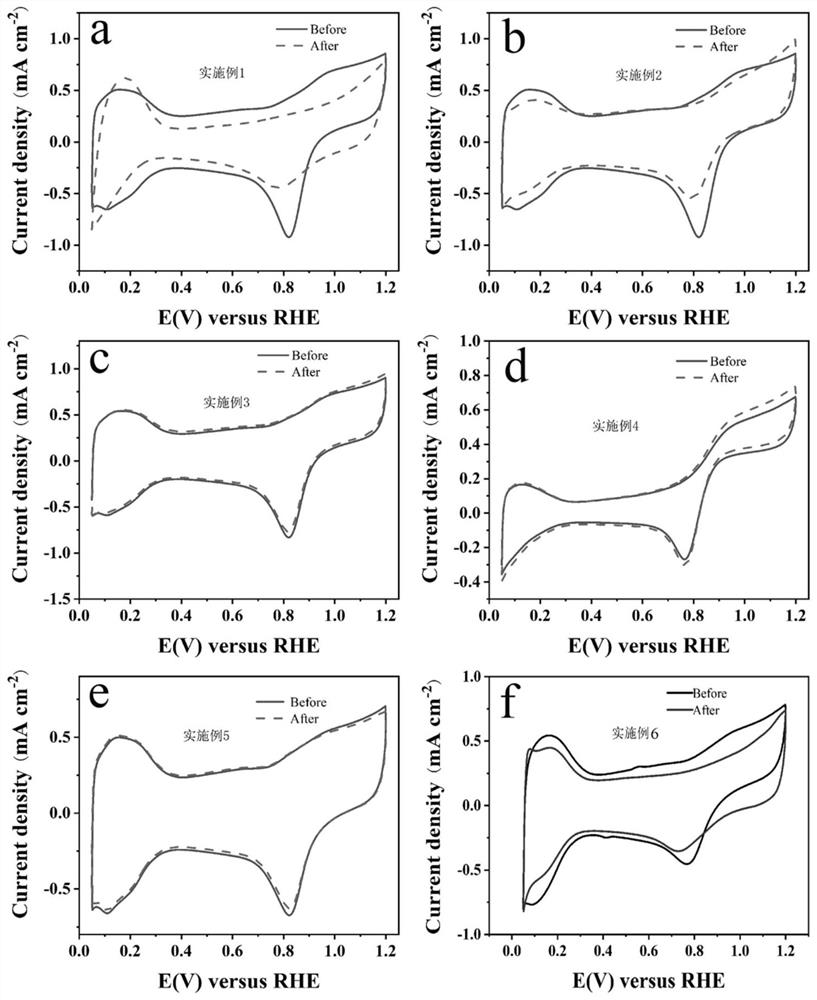

[0037] Embodiment 1 (comparative example)

[0038] A kind of preparation method of the PtPdIr / C catalyst without carbon coating of the present embodiment, described method specifically comprises the following steps:

[0039] (1) the nano-carbon black ultrasonic dispersion of 50mg is dispersed in deionized water, forms the nano-carbon black dispersion liquid; Chloroplatinic acid (H 2 PtCl 6 ) dissolved in deionized water to form H at a concentration of 0.01M 2 PtCl 6 solution; sodium chloropalladate (Na 2 PdCl 4 ) dissolved in deionized solution to form Na at a concentration of 0.01M 2 PdCl 4 solution; the chloroiridic acid (H 2 IrCl 6 ) dissolved in deionized solution to form H at a concentration of 0.01M 2 IrCl 6 solution; then 3mL of the H 2 PtCl 6 solution, 6mL of the Na 2 PdCl 4 solution, 3mL of the H 2 IrCl 6 The solution is sequentially added to the nano-carbon black dispersion, and ultrasonically mixed evenly to obtain a reaction precursor;

[0040] (2)...

Embodiment 2

[0046] A method for preparing a carbon-coated PtPdIr / C oxygen reduction electrocatalyst of this embodiment, the method specifically includes the following steps:

[0047] (1) the nano-carbon black ultrasonic dispersion of 50mg is dispersed in deionized water, forms the nano-carbon black dispersion liquid; Chloroplatinic acid (H 2 PtCl 6 ) dissolved in deionized water to form H at a concentration of 0.01M 2 PtCl 6 solution; sodium chloropalladate (Na 2 PdCl 4 ) dissolved in deionized solution to form Na at a concentration of 0.01M 2 PdCl 4 solution; the chloroiridic acid (H 2 IrCl 6 ) dissolved in deionized solution to form H at a concentration of 0.01M 2 IrCl 6 solution; then 3mL of the H 2 PtCl 6 solution, 3mL of the Na 2 PdCl 4 solution, 3mL of the H 2 IrCl 6 The solution is sequentially added to the nano-carbon black dispersion, and ultrasonically mixed evenly to obtain a reaction precursor;

[0048] (2) Transfer the reaction precursor obtained in step (1) t...

Embodiment 3

[0054] A method for preparing a carbon-coated PtPdIr / C oxygen reduction electrocatalyst of this embodiment, the method specifically includes the following steps:

[0055] (1) the nano-carbon black ultrasonic dispersion of 50mg is dispersed in deionized water, forms the nano-carbon black dispersion liquid; Chloroplatinic acid (H 2 PtCl 6 ) dissolved in deionized water to form H at a concentration of 0.01M 2 PtCl 6 solution; sodium chloropalladate (Na 2 PdCl 4 ) dissolved in deionized solution to form Na at a concentration of 0.01M 2 PdCl 4 solution; the chloroiridic acid (H 2 IrCl 6 ) dissolved in deionized solution to form H at a concentration of 0.01M 2 IrCl 6 solution; then 3mL of the H 2 PtCl 6 solution, 1.5mL of the Na 2 PdCl 4 solution, 4mL of the H 2 IrCl 6 The solution is sequentially added to the nano-carbon black dispersion, and ultrasonically mixed evenly to obtain a reaction precursor;

[0056] (2) Transfer the reaction precursor obtained in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com