Novel lithium ion battery negative electrode material

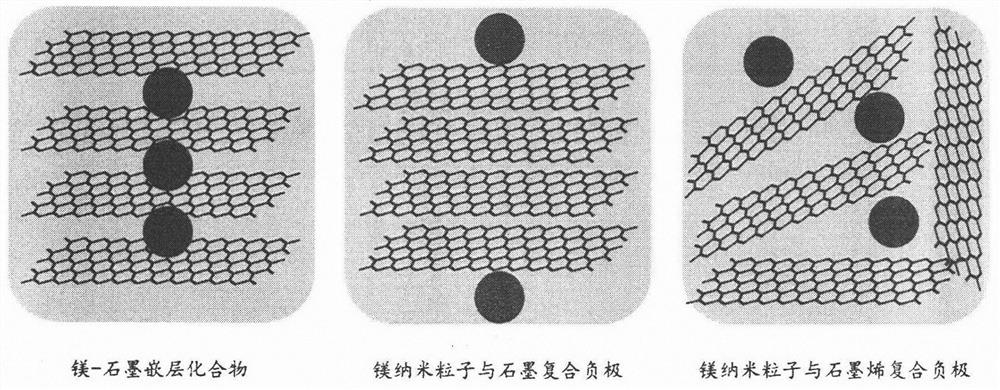

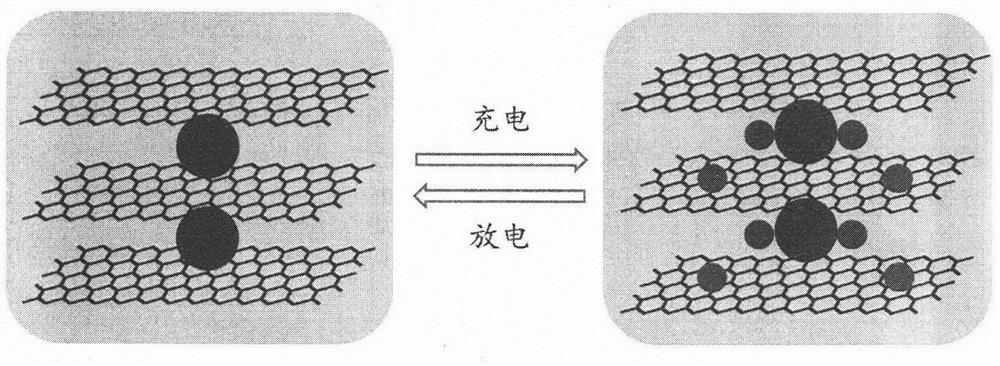

A technology for lithium ion batteries and negative electrode materials, applied in the field of electrochemical energy storage, can solve problems such as loss of efficacy, compression of carbon coating layers, and inability to reduce the degree of volume expansion of alloy negative electrode particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] In a glove box protected by dry nitrogen, a mixture of a certain proportion of natural flake graphite and anhydrous magnesium chloride (MgCl2) was put into a heat-resistant glass tube and sealed with a rubber stopper. After taking it out from the glove box, connect it to a vacuum drying system, and evacuate it to below 0.133Pa. Then, 0.05MPa of high-purity chlorine gas was introduced, and after fusing and sealing, it was placed in a constant temperature reaction furnace, and the temperature was raised to 650°C at a certain heating rate, and kept for 15 days. After cooling in the air, break the glass tube, wash the excess MgCl2 with deionized water, soak it once with anhydrous acetone, and then dry it in vacuum at 100 °C for 12 hours to obtain the magnesium chloride-graphite intercalation compound (MgCl2-GIC ). Put the prepared MgCl2-GIC into a tube furnace, pass in Ar / H2 mixed gas, gradually raise the temperature to 300°C and maintain it for 24h, that is, the Mg-GIC is...

specific Embodiment 2

[0020] In a high-purity argon-protected glove box, add a certain proportion of natural flake graphite and metal magnesium powder into the hydrothermal reactor, then add a certain amount of ethylenediamine, seal the reactor, and react at 100°C for 15 days . After the reaction, the product was taken out by centrifugation. Then, under the protection of high-purity nitrogen, it was heated to 250°C to obtain Mg-GIC.

specific Embodiment 3

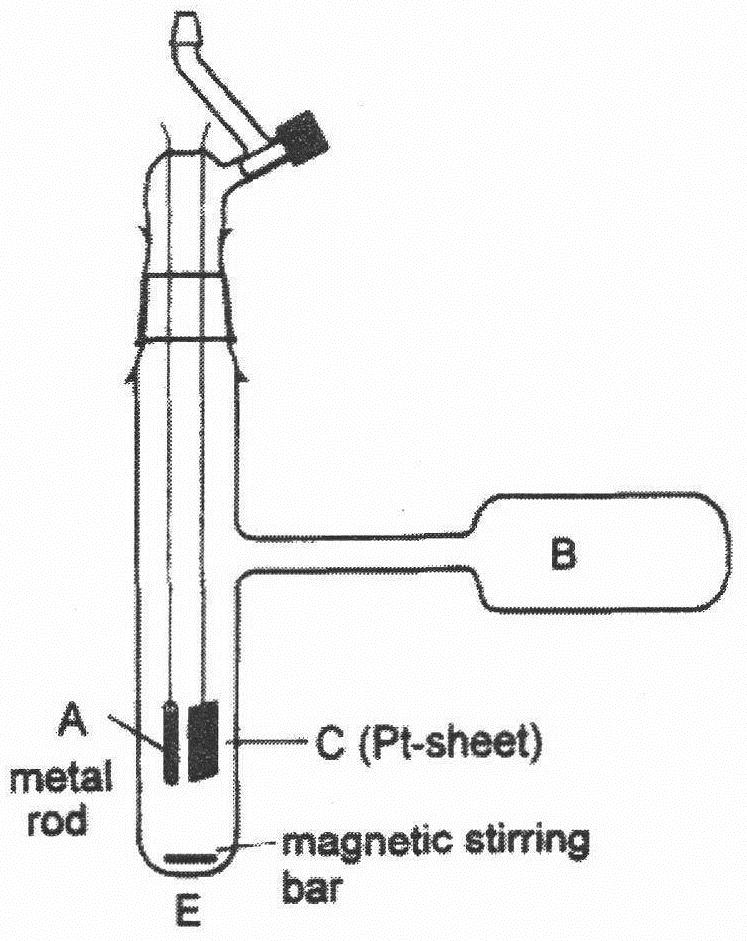

[0022] In a high-purity nitrogen-protected glove box, weigh a certain mass of ammonium iodide (or ammonium perchlorate) and natural flake graphite into the electrolytic cell, and place the electrolytic cell in a cold trap at -60°C. Then the high-purity ammonia gas is passed into the electrolytic cell, the ammonia gas is condensed into liquid ammonia, the ammonium iodide is dissolved in the liquid ammonia, and the natural flake graphite is completely immersed in the liquid ammonia. Electrolyze for 2 hours with a metal magnesium rod as an anode and a platinum sheet as a cathode. After filtration, the product was washed three times with liquid ammonia, and air-dried in a glove box to obtain Mg-GIC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com